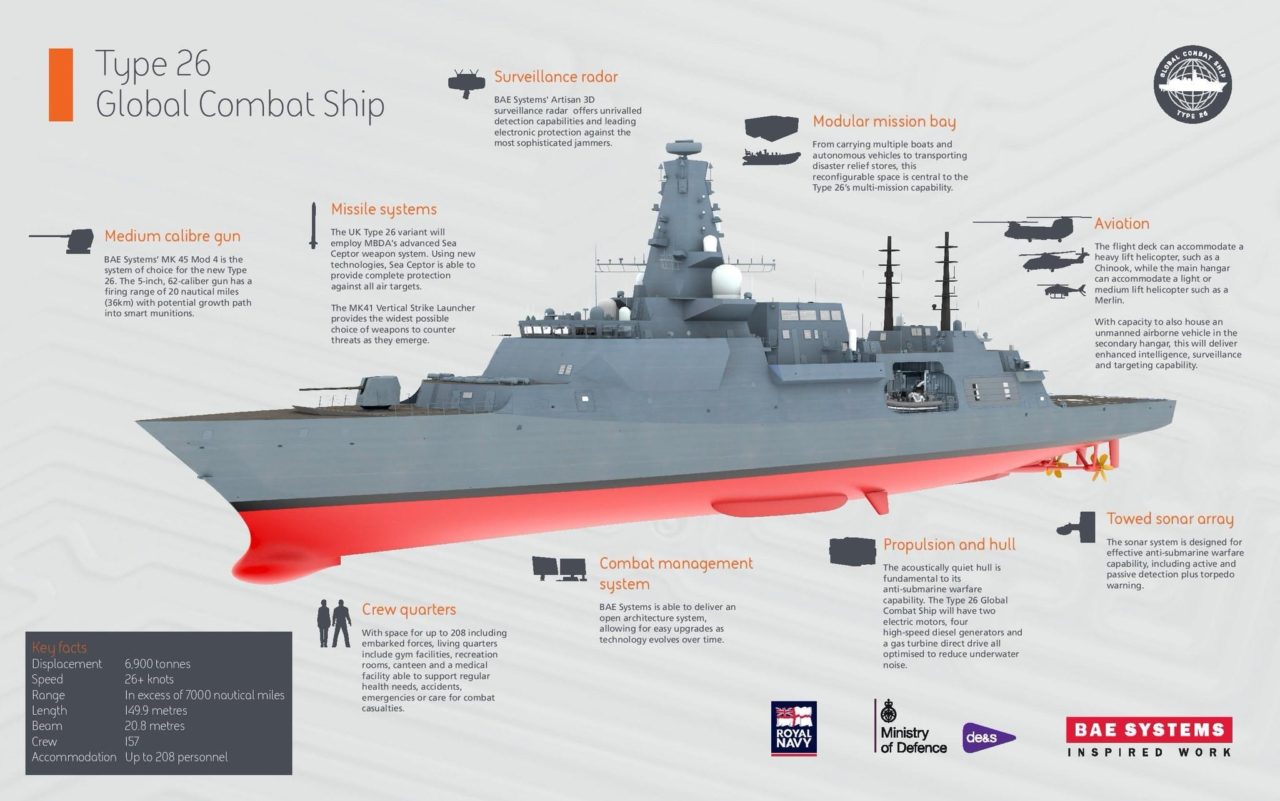

The capabilities of the Type 26 Global Combat Ship that will replace the Type 23 frigate as the workhorse of the Royal Navy Fleet, undertaking the Royal Navy’s three core roles – warfighting, maritime security and international engagement.

Share on twitter

Twitter

Share on facebook

Facebook

Share on linkedin

LinkedIn

Share on reddit

Reddit

Share on print

Print

It is probably fair to say the Royal Navy Type 26 Global Combat Ships will be extremely capable, equipped with a variety of state of the art systems.

De-Risking the Type 26

The Royal Navy has taken a sensible approach with the Type 26 by de-risking many of the systems on other ships, notably the Type 23 Frigate.

From an old Royal Navy publication;

To reduce programme risk, and in keeping with the principles of through-life capability management, there is a drive to maximise pull-through from the Queen Elizabeth-class aircraft carriers, Type 45 destroyers and ongoing Type 23 capability sustainment/upgrades, in an effort to both reduce risk and capitalise on previous investment, and/or existing system inventory. So while the Type 45 is characterised by approximately 80 per cent new to service equipment and 20 per cent reuse, these percentages will be effectively reversed for Type 26

The air defence system, gas turbine, countermeasures, helicopter handling, combat management system, medium calibre guns, sonars and even the chip fryers will be in service on ships other than Type 26 GCS before they are in service on the Type 26 GCS. There is, of course, design and engineering challenges, but at least, there are no major systems to develop in parallel, like with Type 45 for example.

Some of the physical systems from Type 23 may be transferred to under construction Type 26’s, depending one would assume, on crossovers between out of service, build and in-service schedules. Type 23 has been continually upgraded but the most recent package of improvements has been defined as the Type 23 Capability Sustainment Programme (CSP).

The slide above is merely an indicator but it provides a good overview of the planned upgrades.

Combined with a number of equipment obsolescence changes that improve the life of the hull and superstructure, the CSP has started to be incorporated into the existing Type 23 fleet, the first being HMS Argyle.

This Life Extension (LIFEX) to HMS Argyl, for example, not only added the ARTISAN radar and Sea Ceptor missile system but also such seemingly mundane improvements as a chilled water ring main and new paint. All these will inform Type 26.

General Arrangements

In line with contemporary ship construction methods, there has and will be a great deal of thought and effort put into ease of upgrade, reflecting the likelihood of major systems change over the life cycle of the ships. Blown fibre optic cable, block construction, COTS computing hardware and prefabricated internal fixtures like accommodation spaces are just a few of the features that are designed to keep construction and refit costs down.

Clean lines, faceted construction and carefully chosen materials are designed to reduce the ships electromagnetic signature although there are of course obvious limitations in this regard.

- Displacement 6,900 tonnes

- Length 149.9 metres

- Maximum beam 20.8 metres

- Top speed 26+ knots

- Range in excess of 7,000 nautical miles in Electric-Motor (EM) drive

Major Equipment

The Type 26 Global Combat Ship (GCS), or Frigate, is designed to fulfil a variety of missions but the main one is combat operations, at a high tempo and against a peer enemy.

Admiral Sir Philip Jones described Type 26 well;

The distinction is that the Type 26 is a high-end anti-submarine warfare frigate, and it is deliberately designed to be so. Its design enables it to provide high-end protection both to our continuous at-sea deterrent forces and to our future carrier strike groups, and it is deliberately designed to be resilient, noise-quietened and highly effective in countering peer and near-peer threats in the anti-submarine warfare environment.

It is this focus on ASW that sets Type 26 apart from Type 31.

Power and Propulsion

Anti-Submarine Warfare (ASW) requirements influence the hull design and means of propulsion.

The ability to tow a large sonar array, a low acoustic signature hull and the ability to carry out ‘sprint and drift’ manoeuvres are essential to anti-submarine warfare. In the future, there may be technological developments such as offboard unmanned netted sensor swarms that change the requirements in the lifetime of Type 26, but for now, the Type 23 concept is still relevant and still, therefore, the design route is chosen.

The propulsion and power configuration is COmbined Diesel eLectric Or Gas (CODLOG), sometimes called CODELOG, from Rolls Royce;

A CODELOG (Combined Diesel Electric or Gas Turbine) configuration is to be deployed in the Type 26 Global Combat Ship. The diesel gensets supply electric power for on-board systems and for vessel propulsion in cruising mode. The Rolls-Royce gas turbine will be switched in for high-speed propulsion whenever needed. The propulsion concept is ideally suited for the mission profiles of the future combat ships. For naval applications, the MTU gensets have double-resilient mounting systems and are housed within acoustic enclosures. This creates a propulsion system with an extremely low level of acoustic emissions, making the ship very difficult to locate

The important difference between Type 26 and other similar vessels is the Or (O) instead of And (A) in CODELAG. Two presentations and papers that describe the differences can be found here.

For high speeds, the gas turbine drives the twin shafts through a splitting gearbox and then a reduction gearbox.

At lower speeds, where low noise is absolutely critical, the turbine and associated gearboxes are shut down and the shafts driven by General Electric Power Conversion induction motors. The motor speed is controlled by adjusting its frequency through another GE Power Conversion product, the MV3000 marine converter. Unlike Type 23, which uses changes in DC voltage, Type 26 will change the fixed AC supply to DC and then adjust the waveform supplied to the motor using a technique called Pulse Width Modulation (PWM). The MV3000 at the heart of the system is widely used in the marine industry and so support issues with unique equipment should be reduced, although for use in naval applications shock protection and noise reduction are key changes.

Commenting on the contract award, Mark Dannatt, GE Naval Systems Lead said;

Reducing radiated noise from the motor makes it exceptionally quiet, which is obviously very important for naval operations. GE is on the cutting edge with this proven, robust technology. It will allow the Royal Navy to operate more efficiently, cost-effectively and safely. Drawing on our extensive experience over decades in the electrical power conversion systems industry, we are moving to provide the latest in motor and drive technology that is at the forefront of operational efficiency

Rolls Royce will supply a single 36-40 MW MT30 Gas Turbine for each Type 26 GCS, the same as fitted to the QE Class carriers.

Rolls Royce describe the MT30 as;

Designed with approximately 50 per cent fewer parts than other aero-derived gas turbines in its class, to minimise maintenance costs, the MT30 has a twin-spool, high-pressure ratio gas generator with free power turbine. It maintains operating efficiency down to 25MW and can be configured in either mechanical, electrical or hybrid drive configurations

The diesel generators will be from MTU, the same Type 20V 4000 M53B as used on the German F125 Frigates. Each ship will have four of them in a double resilient acoustic enclosure.

In August 2015, the MoD awarded a £68 million contract to Rolls Royce for the provision of 48 MTU 12V 4000 M53B gensets, training and logistics support. Twelve Type 23’s will get four of the 1,650kW systems each. Although not identical to the 20V 4000 M53B gensets planned for the Type 26 one wonders if there is a high degree of commonality that will enable some rework and transfer?

(if you want a double-decker infographic that the MoD seems keen on, click here)

David Brown Gear Systems will provide the reduction gearboxes and a load test rig, DCNS the shaft lines and, making an assumption, Rolls Royce, the propellor.

The image of engineering beauty on the right is a Type 23 fixed-pitch propeller in the National Maritime Museum.

The low noise fixed pitch propellers as fitted to the Type 23 can run on a diesel-powered electric drive at about 90 RPM or 13 to 17 knots. The slow rotation speed and fixed pitch propellers are used to lower the onset cavitation and radiated noise that might interfere with the sonar systems.

Rolls Royce will supply the Type 26 GCS propellors, steering gears and stabilisers.

Finally, WR Davis will provide the engine uptakes and down takes.

[the_ad id=”53393″]

Computing and Communications

The primary interface between the ships equipment and its crew will be the combat management system and this will likely be the latest iteration of the Outfit DNA(2)/CMS-1 from BAE. In January 2011, BAE was awarded a £47m contract to support the combat management systems aboard the Type 23 Frigates and RFA Argus.

A good description of what a CMS does can be found at BAE;

The CMS assists a ship’s command in detecting and countering threats to the ship and any surrounding forces by managing all relevant external and internal information provided by the ship’s radars. It integrates this information with the activities of the anti-air weapons systems as well as other sensors and weapons.

The press release describes the Joint Support Solution which is a wider commercial framework incorporating the same systems on Type 45, CVF and future ships. In March 2012 year, BAE was awarded another related contract, in conjunction with QinetiQ. The £45m award covered specialist tests, integration and approval of naval combat management systems and this, or at least a future extension/variant, will likely include work on the Type 26 programme.

The Surface Ship Combat Systems (SSCS) DNA system has had a difficult introduction into service. Originating in the Surface Ship Command System (SSSC) programme it was selected in 1989 after another advanced combat management system had failed. Does anyone remember Token Ring or IEE802.5, DNA(1) used this with fibre optic networking and combined such cutting edge systems as 3.2Gb storage arrays, Pentium processors and colour displays!

The Type 45 command and combat system is an evolved derivative of the DNA(1) system with elements from other programmes and run over a Fast Ethernet network. It wasn’t until 2010 that the first Type 23, HMS Montrose, was put to sea with the upgraded DNA(2) system, 4 years after the initial contract award to BAE that would also see the same system being deployed in the future surface vessels and another variant for submarines. A significant feature of DNA(2) is that it is based on commercial hardware and software.

The Type 26 GCS will have a common computing infrastructure that makes use of open architecture systems for ease of technology insertion and change management.

BAE will be introducing a shared computing environment based on modern blade server architecture and operating systems virtualisation on Type 23 and this will be transferred to Type 26. Given the rapid rate of development in computing equipment and long timescales between design and introduction of the Type 26 GCS this kind of technology, mundane and ordinary in the civilian world, will allow the ship computing environment to avoid obsolescence issues that limit effectiveness and drive up support costs as manufacturers struggle to find stocks of Intel 486 processors, for example.

The pace of change in IT equipment seems as rapid as ever and in a decades time when the Type 26 GCS is in service the computing power on offer in the open market will no doubt be hugely different than that today. Data growth is a key issue and by enabling the use of commercial hardware, opportunities to exploit this increasing amount of data can be realised at reasonable costs. Future unmanned systems will no doubt add to this data growth and the Type 26 must be ready for it.

Aish Technologies provide blade server enclosures, displays and consoles to the Royal Navy.

Type 26 Visualisation below

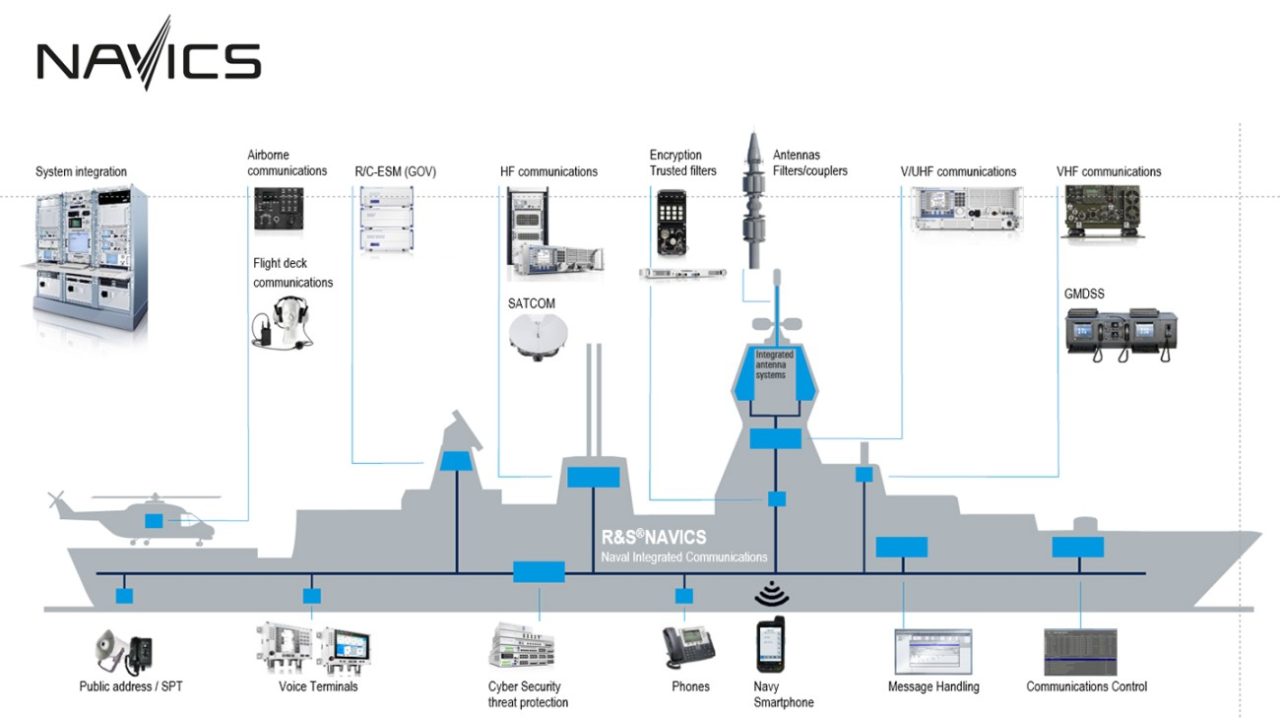

Rohde & Schwarz will provide an integrated internal and external communication system based on its NAVICS IP switching system that has been specially hardened to protect against physical and cyber disruption.

i.Safe ATEX Smartphones with a graphical user interface will be employed to provide ‘man on the move’ communications and fixed terminal provided as required throughout the ship.

The full system scope will include

- Tactical Voice System and Communications Control Subsystem (TACV/CCS), where TACV provides state of the art internal and external Voice-over-IP (VoIP) communication and CCS provides control and monitoring of equipment plus the definition and activation and management of navy specific communication plans;

- Administrative Telephony and Wireless Communication System (ADTEL/WCS), where ADTEL enables the communication between crew members on the vessel, and WCS providing mobile voice terminals for the full range of communication;

- Broadcast and Alarms System, providing broadcast communication and alarm notifications on the ship (Lloyds approved); and

- Self-Powered Telephones, providing emergency point-to-point and group voice communications.

- HF communications, providing extended range beyond-line-of-sight (BLOS) communications, tactical voice communications and the exchange of high-grade messages;

- V/UHF Line of Sight Communications, providing line-of-sight (LOS) voice and data communications with military and civilian air, sea and shore assets;

- Land Forces Tactical Communications, providing tactical communications with land forces; and

- Integration of 3rd party external communication – Military SATCOM (MILSAT), Global Maritime Distress and Safety System (GMDSS), Civil SATCOM, Video Teleconferencing (VTC)

Software-Defined M3SR (series 4100 and 4400) VHF/UHF and HF transceivers will provide external radio communications, making use of an R&S designed mast and a range of supporting ancillaries such as terminals, filters, power supplies and racks.

In addition to the announced HF/VHF/UHF radios, the Type 26 GCS will most likely be fitted with the full complement of SHF satellite communication systems, IFF, underwater telephone, 3G, GSM, LTE and Link 11, 14 and 16 JTIDS.

Anti-jam antennae from Novatel will be fitted for navigation and timing.

The Type 45 satellite communications were designed and installed by BAE, Thales and EADS Astrium, the latter responsible for the Satellite Communication Onboard Terminal (SCOT) 3 equipment. Type 23 satellite fit also uses SCOT equipment so it is possible, Type 26 will use the same.

Datasheets for SCOT Patrol and SCOT Mission, here and here.

Civilian systems such as Iridium or Inmarsat are also likely to be fitted.

The communication masts will be provided by STS Defence and Mainstay Marine.

Radar, ESM and Electro-Optical Sensors

The main radar will be the BAE Type 997 ARTISAN 3D system.

Now fitted to the type 23 frigates, Advanced Radar Target Indication Situational Awareness and Navigation (ARTISAN) is an advanced medium-range 3D radar with a high level of resistance to jamming, providing air surveillance, target identification and air traffic management services. The ARTISAN antenna weighs in at about 700kg the systems as a whole, developed at a cost of over £100m

https://www.youtube.com/watch?v=8ZhD9BxDNpQ

Actual capabilities remain classified but it is reportedly capable of tracking in excess of 800 objects at a range of 200km.

There are also a couple of smaller and less sophisticated systems from Kelvin Hughes used on the Type 23 Frigate. The Kelvin Hughes Type 1007 and now Type 1008 is used for surface warning and navigation. Both are considered legacy equipment and so less likely to be transferred from the Type 23, instead, the Kelvin Hughes Sharpeye digital radar systems will probably be used for navigation, obstacle avoidance and helicopter flight operations support.

There are plans for the Type 23 to receive a navigation radar upgrade and if this happens, again, the systems may be a straight transfer. It was subsequently announced that the Terma Scanter 6000 would be used.

https://www.youtube.com/watch?v=fUUmxLVbo80&ab_channel=TERMAGroup

Lockheed Martin was awarded a £44m contract for navigation radars across multiple Royal navy platforms in 2016, with Kelvin Hughes as a key sub-contractor, the Vigilance radar software from LM combining with Kelvin Hughes radar. Cambridge Pixel’s software modules for radar scan conversion, target tracking and radar fusion will be used as part of the Vigilance system. In May 2012, Thales announced the award of an earlier contract to upgrade the Royal Navy major surface fleet with their Fully Digital Radar Electronic Support Measures (RESM) as part of the UAT Mod 2 programme.

Under the terms of the new contract – the UAT MOD 2.1 & 2.3, advanced technology will be now be introduced to the UAT RESM equipments fitted across the RN surface fleet and associated land-based training equipments. The technology provides excellent system performance in the modern dense radar environment. This enables the ship to operate in all operational maritime theatres, including the littoral environment, and provides the RN with world leading electronic warfare support and emitter identification technology. By digitising the RF signal at the antenna, the majority of the receiver functionality is implemented using software and firmware algorithms. The system is therefore easily upgraded and new signal analysis tools are easily introduced, keeping the RESM capability current in a rapidly evolving operational environment. The approach also maximises the use of commercial off-the-shelf hardware, making the RESM significantly more reliable, easier to maintain and lowers the total cost of ownership.

In a nutshell, they detect, locate, classify and report signals intelligence data in real-time, overall, a very advanced system.

[the_ad id=”53393″]

Cooperative Engagement Capability now seems to be firmly off the agenda, if one looks at the images below, on the left is an older image of Type 26 with the CEC panels (the square ones) and the latest image on the right, without. Incidentally, the pyramidal shapes arranged around the mast are the ESM receivers described above.

The Sharpeye navigation radar and SCOT satellite radomes can also be seen.

The mast itself will be built by Umoe Mandal AS in Norway.

The shapes at the base of the mast that look like beer barrels are electro-optical sensors, the Ultra Electronics SERIES 2500 EO System that is standard equipment fit on Type 45 Destroyers.

The stabilised sensor is called the Electro-Optical Director (EOD) and this is linked to a system console called the platform Control Cubicle (PCC). The system can be cued manually or automatically (including from radar and other systems), track moving objects with its long-range TV and Infra-Red sensors, perform target identification and provide ballistic fire control information for the ships gunnery equipment.

Subsequent to the initial imagery, Chess Dynamics (in conjunction with EOS Australia) was awarded a contract to provide their Sea Eagle electro-optical systems for Type 26.

HGH Infrared Systems manufacture panoramic thermal imaging systems, working in a QinetiQ led project they will supply their Spynel-M products for integration with the Compact Combat System (C2S) that will combine a Kelvin Hughes SharpEye radar and a Chess Dynamics Sea Eagle. The system is primarily designed to counter the small fast inshore attack craft (FIACs) threat. Information from the three sensors and AIS data is integrated with the Enhanced Situation Awareness From Existing Sensors (ESAFES) fusion engine and presented to a single display and cueing information provided to on deck automatic weapons via an Ethernet link.

Although this is only a research project this kind of technology might find its way onto Type 26 GCS

Acoustic Sensors

The hull-mounted Ferranti/Thomson Sintra Type 2050 sonar on Type 23’s has a long and complex history with many changes of ownership but the base product is now part of the Thales UMS 4110 family and utilises much of the processing and display console systems as the CAPTAS 4 or 2087.

From Jane’s;

Sonar 2050 is the medium-range, medium-frequency hull-mounted attack sonar for the Royal Navy fitted to the Type 42 destroyers and Type 23 and Type 22 frigates. It is the successor to Sonar 2016 and is compatible with both bow and keel variants of the Sonar 2016 array

In February 2014, Thales received a 5-year support contract for the thirteen Sonar 2050 on Type 23 Frigates and then strangely, Ultra received a £27 million contract in December 2014 for the Sonar 2050 Technology Refresh Programme that will upgrade and support for ten years, 2050 sonar systems on eight Type 23 Frigates.

Whether the Type 2050’s will be transferred to Type 26 or a new purchase of the UMS 4110 (or another type), is not yet known. In addition to the Sonar 2050s, eight of the Type 23 Frigates are fitted with the very sophisticated Sonar 2087 Variable Depth Sonar (Thales CAPTAS 4) that is designed to detect submarines at ranges greater than they can launch attacks.

Sonar 2087 can be operated ‘hands-free’ up to Sea State 6 and to a depth of 250m, a very important aspect of the system capability and one that has a clear origin in Cold War North Atlantic NATO missions. In addition to the processing, displays and handling equipment, the core components are two towed items, the towed body and towed array, one active, one passive, that can be deployed at variable depths.

Detection in shallow waters is a problem because underwater obstacles might prevent the safe deployment of long towed arrays, fresh/seawater mixes, tidal impacts on water conditions, unpredictable and variable salinity/temperature, reflections from the sea bed and underwater obstacles and even concerns about underwater wildlife may limit the use of low-frequency devices.

Ambient and directional noise from man-made and natural sources also confuses the overall acoustic picture. Because of the smaller areas involved accurate seabed surveys and sediment analysis, sometimes called Rapid Environmental Assessments, can be used for ASW. This kind of technology and processes are more often used for survey and mine countermeasures but research continues at a pace and one capability may very well utilise another.

We might see the kinds of USV’s now routinely used for covert survey and seabed analysis carried onboard a Type 26 GCS in the future. Other promising research avenues include exploiting so-called ‘non-cooperative sound sources of opportunity, other ships that just happen to be in the area for example. The returns from these can be passively received into the detection and analysis software, cunning eh?

It is likely that the Sonar 2087’s will be a direct transfer from Type 23 to Type 26.

Anti-Air Missile Systems

Providing self (and possible small area) defence against aircraft and anti-ship missiles will be the Sea Ceptor system.

Sea Ceptor was previously known as Future Local Area Air Defence System – Maritime (FLAADS(M)). The MBDA Common Anti-Air Modular Missile or CAMM is one of the core UK Complex Weapons programmes that are intended to replace the Sea Wolf Block 2, ASRAAM and Rapier FSC missile systems in service with the Royal Navy, Royal Air Force and Royal Artillery respectively under the Future Local Area Air Defence System (FLAADS) requirement.

It is intended to maximise commonality across all three services in order to minimise logistic and support costs. FLAADS(M) for Maritime, FLAADS(L) for Land and FLAADS(A) for Air were all intended to be delivered with the Common Anti-Air Modular Missile. The modular design is also intended to facilitate lower the cost of through-life incremental upgrades.

MBDA describe it as;

FLAADS(M) provides a true 360° air defence capability for naval forces out to ranges greater than 25km against the future air threat. Requiring no dedicated tracker/illuminator radars, CAMM can be cued by ship target indication data to provide high levels of protection in open ocean and littoral environments. It can also be used against surface targets. The weapon system, which incorporates a 2-way data-link capability to CAMM missiles in flight, is intended for vessels of corvette size or larger, for either new ships or as a retrofit. It will provide self and consort defence whilst operating with 2-D and 3-D radars and has an architectural design to allow integration within a variety of combat systems. CAMM can operate from SYLVER and Mk41 family launchers utilising features such as folding missile fins to maximise packing density. For smaller ships, a simple bespoke quad-pack launcher (occupying the same space as a Seawolf canister) will be available. The introduction of “soft launch” techniques reduces system mass and eases installation. MBDA has taken a Through Life approach in developing the CAMM solution. New weapon system architectures that reduce customer costs by removing expensive components are now possible. MBDA’s PAAMS (Principal Anti-Air Missile System) naval self, local and fleet area defence weapon system has now established a preferred architectural approach to air defence. FLAADS(M) follows this approach by re-using software and substituting new low cost components.

The missile itself takes a great deal from ASRAAM but it is not a surface-launched ASRAAM with a new name. Common components include the very low signature rocket motor from Roxel, the warhead and the proximity fuse from Thales. The seeker and open architecture electronics backbone are new, the latter is called Programmable Open Technology for Upgradable Systems or PrOTeUS and uses an IEEE 1394 Firewire bus technology as a starting point.

Sea Ceptor differs from Sea Wolf in a number of respects but the most significant is the elimination of a requirement for dedicated fire control radar. By removing this reliance on fire control radars, the data link and two-way active radar homing seeker is designed to overcome saturation attacks and has the additional benefit of removing a piece of equipment from the support chain.

Although range will, of course, be classified MBDA declare it as ‘in excess of 25km’, which in any case is better than Sea Wolf and Rapier, at 99kg it is nearly 20kg heavier than Sea Wolf and over 50Kg heavier than Rapier.

The Common Data Link (CDL) is the small ‘black box’ that sits on top of the mast, especially clear in pictures of FLAADS(L) although it doesn’t necessarily have to use the two-way data link to the launch vehicle, so, it could take mid-course corrections from any number of suitably equipped land or air platforms and then switch to active homing when it gets close enough. The original launch platform could have even moved by the time the missile hits. Type 23 frigates will be fitted with two CDL’s.

It is reported that each missile in its sealed canister will have a shelf life of ten years and although MBDA claims it can be quad packed in either an SYLVER or Mk 41 launcher current images suggest they will be installed on Type 26 in a bespoke low-cost launcher. The soft vertical launch system ejects the missile to a height of about 30m using an enclosed gas piston before a small thruster fires to orientate the missile with the target location. This method is safer, removes the need to manage hot gas efflux in the launch silo and ensure all of the main rocket motor fuel is used for arriving at the target.

The location and configuration of the Sea Ceptor silos were subject to a great deal of debate and speculation. Models and CGI’s have variously shown multiple locations and silo numbers but they will be in a physically diverse arrangement with one silo block behind the gun and another adjacent to the funnel, 24 missiles in each location. The Sea Ceptor missile can also be quad packed inside an Mk41 cell and MBDA has indicated it may have some anti-surface capability.

Surface and Land Attack Missiles

The first design iteration of Type 26 showed amidships Harpoon launchers but they disappeared in later versions.

Type 26 GCS will be fitted with a Lockheed Martin Mk41 Vertical Launch System (VLS), current imagery suggests 3 modules, a total of 24 cells. Like the SYLVER VLS fitted to the Type 45, the Mk41 provides a compact means of storing and launching vertically launched missiles, and specifically, a means of managing the hot exhaust.

The rocket exhaust is directed into a chamber and then vented upwards through an aperture to the surface. It is available in a number of different lengths, the longest referred to as ‘Strike Length’, at 7.6m long.

All good, the Mk41 is a widely used system with many options for filling it, unfortunately, the Royal Navy does not have any weapon system in service that can utilise them.

At the UK/French 2016 Summit an intent to co-develop a joint concept phase for the Future Cruise/Anti-Ship Weapon (FC/ASW) programme was announced. Storm Shadow was subject to a Mid-Life Refurbishment (MLR) that will meet the SPEAR Capability 4 requirement, and take it to its planned out of service period of around 2030, when it will be replaced with the SPEAR Capability 5 system, nominally, the UK/France Future Cruise and Anti-Ship Weapon (FCASW) / Futur Missile Antinavire/Futur Missile de Croisière (FMAN/FMC).

The MoD provided greater detail the following year;

The Type 26 Frigate will be delivered with cutting edge weapons and sensors that build on the excellent operational record of the Type 23. Investment in the MK 41 launcher enables the Royal Navy the option of investing in a wide range of additional capabilities at short notice and according to the threat. The Type 26 Global Combat Ship will be fitted with the Mk41 Vertical Launch Silo, providing options for development of Type 26 capability throughout its life. Type 26 is planned to be a key component of the RN’s fleet until at least 2060 and it makes sense to build a strike missile launcher into its design that enables a flexible choice of weapons throughout its service life.

The Mk41 Vertical Launch silo provides the flexibility to field a variety of weapons, which may include the next generation of ship-launched strike weapons – including the Future Offensive Surface Weapon and the Next Generation Land Attack Weapon – being developed through the MOD’s current ten-year, £178 billion equipment plan.

The current planning assumption is that Future Cruise /Anti-Ship Weapon will enter service on the T26 Frigate and Typhoon aircraft in 2028 and 2030 respectively

Guns

The images show the Dillon Aerospace M134 Miniguns (Mk44) and GPMG

Fitted to both the Type 45 and Type 23 are MSI 30mm automatic cannon systems and 20mm Phalanx Close-in Weapon System (CIWS), again, these feature in the latest graphics of Type 26

The MSI mounts have a long heritage with the first designs being introduced in the early eighties with the 30mm RARDEN cannon. In the mid-eighties, the Royal Navy selected the Oerlikon 30 mm KCB to replace all existing 20mm and 40mm automatic cannons as a post-Falklands lesson learned exercise. First entering service in 1988 they have been continually refined and the latest version is the DS 30B Mk2 equipped with off-board sensors, the ATK 30mm Bushmaster Mk44 cannon (instead of the Oerlikon) and Seahawk fire control systems that are replacing all previous versions on Type 23 by 2014 in a £15m contract with MSI.

It is officially called the Automated Small Calibre Gun (ASCG)

The Raytheon Phalanx is a multi-barrel close-in weapon system primarily for use against anti-ship missiles although it retains some capability against surface targets.

UK Phalanx has been variously upgraded, used on trailer mounts for C-RAM in Iraq and Afghanistan and converted back to the maritime role. The latest version is the 1B that upgrades a number of components and adds a visual cueing and tracking system for use against surface targets. In addition to providing the 1B upgrade, Babcock has a ten-year support contract for the 36 Phalanx systems, based on providing availability of the systems throughout their life on board ship. On Type 26 GCS, the Phalanx position has changed with each graphic and the latest version shows them in the same position as on Type 45, one on each side.

After much speculation and competing bids from Oto Melara/Babcock, the BAE GCS will feature a BAE Mk45 Mod 4 medium calibre gun system.

The Future Maritime Fires Concept Phase completed a few years ago, no doubt lessons from Libya (where HMS Liverpool fired over 200 rounds of 4.5” ammunition) will have played a large part in informing the study. With the cancelling of the BAe 155mm TMF project that used the gun system from the As90 Self Propelled Gun, the choice of a naval gun narrowed.

Question

Julian Lewis (New Forest East, Conservative)

To ask the Secretary of State for Defence what his policy is on the replacement of existing warship guns by ones of 155mm; and if he will make a statement on his policy, with special reference to (a) the future frigate fleet and (b) Type 45 destroyers.

Answer

Peter Luff (Parliamentary Under Secretary of State (Defence Equipment, Support and Technology), Defence; Mid Worcestershire, Conservative)

No decision on the calibre of the new Maritime Indirect Fire System (the new naval gun) has yet been made. This will be taken when work to consider the available options under the Future Maritime Fires Concept Phase is complete in around mid-2012

The Maritime Fires Concept, of which the Maritime Indirect Fire System (MIFS) is being delivered in conjunction with the Niteworks Partnership and is expected to be met by a medium calibre gun (MCG). The other part of MFS is the Maritime Indirect Fire Precision Attack (MIFPA) is expected to be delivered using missile systems, potentially Fire Shadow, although the status of the latter would seem to preclude this option going forward.

Naval Gunfire Support has a great deal of utility and is used much more often than many of the more esoteric systems, the Falklands, Iraq and Libya being recent outings; it is much cheaper than using air-delivered munitions if circumstances permit and can use a graduated force model where a well-aimed smoke or illumination round that signals loud and clear the next one will be of the type that goes bang can influence subsequent activity or neutralise threats both on land and at sea.

The existing 115mm/4.5” Mark 8 Mod 1 gun aboard Royal Navy vessels has its origins in the late sixties and has given excellent service but how reliable they are now is apparently an open question. The HE Extended Range round uses base bleed to propel the round to a maximum range of 27.5km and the existing illumination nature is also still available. In order to maintain a sustained rate of fire of 16-20 rounds per minute and accommodate the more powerful ammunition types, the barrel is 62 calibres long. It has seen extensive service including the action of the Falkland Islands (8,000 rounds), Iraq and Libya.

The Mark 45 Mod 4 from BAE, as used by the US Navy, South Korea, Denmark, Australia and others, is a 5”/127mm system with a 62 calibre barrel and is capable of a rate of fire up to 20 rounds per minute, the magazine will contain 196 rounds.

BAE describe it as;

The 5-inch (127-mm) 62-caliber Mk 45 Mod 4 Naval Gun system is in U.S. Navy and Allied service today, and is ready to significantly enhance Naval Surface Fire Support (NSFS) and overall mission performance. Major upgrades of the Mk 45 Mod 4 include a 62-caliber barrel, strengthened gun and mount subsystems, advanced control system enhancement, and a reduced signature, low maintenance gun shield. The Mk 45 Mod 4 provides NSFS range of more than 20 nautical miles (36 km) with the Navy’s new 5-inch Cargo projectile and an improved propelling charge. Operation and performance of extended-range munitions are tailored for optimal effect and range in unison with the major subsystem upgrades of the Mk 45 Mod 4 Naval Gun.

A large installed base allows development costs of precision, proximity, IR illumination or smoke natures to be spread across many users. Adopting such a widely used system means natures such as IR Illumination are immediately available without expensive development programmes.

The magazine and palletised handling system will be a new design for Type 26, taking the existing arrangement and adding improvements derived from the DDG-1000 programme.

https://www.youtube.com/watch?v=HXHsiM09c7I&ab_channel=baesystemsinc

Type 26 GCS doesn’t necessarily need the precision-guided ammunition straight away, the existing Mk45 Mod 4 will provide a modern, accurate and powerful weapon system in its own right, again, another system much improved over Type 23. However, if there is a requirement for precision and additional range, options exist, albeit ones not yet completely in service in the maritime domain. There are a couple of options for extended range and precision effects, Raytheon with their Excalibur and BAE, the Multi-Service Standard Guided Projectile. Raytheon has recently successfully fired their 5″/127mm Excalibur N5 precision-guided projectile from a Mk 45 test mount.

https://www.youtube.com/watch?v=iA_CQLAtCrs

Whether the UK takes any of the options and if so, when, is open for discussion, but at least there are relatively low-risk options available, although, as mentioned above, none is yet in full naval service.

There has also been some discussion of using the Mk5 gun as a projector for anti-submarine munitions, with BAE showcasing their Kingfisher concept in 2019.

“We started out with a discussion of how we could replace the old Mk 11 Depth Charge with a more novel option,” said Murray Thomson, chief technologist for the Underwater Weapons business of BAE Systems Maritime Services in the UK. “Drawing on technologies and expertise from across BAE Systems, we developed the idea of an underwater explosive charge contained in a round fired from [an] Mk 45 gun.” The charge would provide ‘escalatory’ effects according to the prevailing rules of engagement, according to Thomson. “It could be a warning shot, it could be a barrier of charges for area denial, or it could be used to disrupt sonar,”

BAE has since expanded the Kingfisher concept with plans to utilise a sonobuoy payload.

There are no firm plans for any of these guided munitions on Type 26 as yet.

Decoys and ECM

Countermeasures are not often discussed but are advancing all the time and many consider them more effective at protecting against anti-ship missiles than CIWS.

The fixed multi-barrel DLH Launcher as part of the Seagnat system is used to launch a variety of decoys that attempt to confuse, lure away and break the lock of incoming anti-ship missiles. In response to radar and other warning devices, they will launch a pattern of decoys controlled by the ALEX system, used in conjunction with ship manoeuvre to protect the ship.

The Royal Navy and other naval forces have a wide range of decoy or soft kill protection systems (not just from Chemring) but whist the rounds themselves have advanced the launchers have not. T

Active RF Decoy

In 1994 GEC Marconi was awarded £80m contracts to develop their Siren system to fulfil the Royal Navy ‘Outfit DLH’ requirement. It was designed to seduce inbound anti-ship missiles using a launched RF countermeasure (Mk 251 Active Decoy Round) fired from standard 130mm SeaGnat launchers. The system was also to utilise the existing Seagnat launch control systems, 21 ship sets and 720 rounds were obtained with the final cost being in the order of £103m. It did not enter service until 2004, 10 years after the contract award, replacing SeaGnat DLB and DLJ(2).

The product description is;

Siren is an advanced decoy system designed to protect ships from missile threats by luring incoming anti-ship missiles away from their target. Launched from a 130mm decoy launcher it uses a two stage parachute system which slows the decoy round down at a pre-programmed time before deploying a second stage parawing, under which the advanced programmable electronic payload descends to detect and counter the missile threat. The ability of Siren to generate sophisticated jamming waveforms is unique amongst the worlds limited types of naval decoys. The Siren payload contains some of the most up to date RF, digital and analogue electronic circuitry available, enabling the round to quickly detect, identify and track threats to ships. Siren is able to handle multiple threats simultaneously even in dense RF environments.

Siren eventually passed to BAE and then to Selex, a Finmeccanica company. Type 23 Frigates use the Mk 251 Siren so again, a straight transfer to Type 26 GCS might be the most appropriate solution.

A joint UK/French programme called ACCOLADE is investigating advanced RF decoys.

RF and Infra-Red Distraction Decoys

In addition to the advanced Mk 251 Siren, the RN Outfit launcher systems can also use RF distraction (chaff) and IR decoys such as the Chemring Mk 216 Mk 1 Mod 1 and Chemring Mk 245 IR. The Royal Navy has replaced the Mk 245 IR round with the Chemring TALOS that uses variable timing and submunitions rather than a single round, called the A2, as in the image below.

Fitted to the Type 45 is the Airborne Systems IDS300 (now called the FDS3) inflatable RF decoy also looks like it will be fitted to Type 26 GCS, the launchers are the horizontal cylindrical devices adjacent to the missile silos.

The FDS3 is a self-inflating octahedral shaped corner reflector that floats on the surface and unlike chaff, is persistent, able to float for 3 hours in sea state 4

It is a simple and low-cost system, in service with many naval forces.

Electronic Countermeasures

Type 23 Frigates are fitted with the Thales Scorpion 2 Radar Electronic Countermeasures system. Taking information from the integrated ESM system it denies enemy forces the use of their radars; aircraft, ship, missiles, fixed or vehicular mounted device

Type 26 GCS imagery suggests a pair of these will be fitted. There is also a current programme that merges electronic surveillance and countermeasures programmes into a single programme, Maritime Electronic Warfare Programme (MEWP).

Torpedo Defence

Entering service with the Royal Navy in 2004 and replacing the NIXIE system, the Ultra Electronics Surface Ship Torpedo Defence system provides protection against ship or submarine-launched torpedoes, again, it would seem the system will be transferred to Type 26 GCS.

The system, now called Sea Sentor, is described as;

The SEA SENTOR™ Surface Ship Torpedo Defense system has been in-service since October 2004, protecting fleets from the increased threat of torpedo attack. With 16 systems delivered to the UK’s Royal Navy, installations on US naval platforms and a recent order by the Turkish Navy, SEA SENTOR™ is the most advanced system available in the market today. The SEA SENTOR™ system utilizes a towed acoustic passive array especially designed for the detection of torpedoes to classify and localize in-water threats. Tactical advice is presented by the system that is specifically geared to the make, model and current operating mode of the detected threats – single or salvo. Detection ranges to initiate successful defeating tactics are achieved in all conditions; whether operating solo in deep water or in-convoy in busy shipping lanes and littoral waters Countermeasure action is automatically performed according to the tactical advice for the towed system elements. Expendable countermeasures are launched by the operator when prompted to do so.

System components are (from Wikipedia);

- an acoustic passive towed array

- a towed acoustic countermeasure (flexible)

- a single-drum winch

- a processing cabinet

- 2 display consoles

- 2 expendable acoustic device launchers (1 port, 1 starboard)

- 16 expendable acoustic devices (8 in each launcher)

The system is also in service with a number of other nations and an active torpedo ‘hard kill’ interceptor is in development.

The lack of lightweight torpedo launchers seems a curious omission from the information released so far, it is understood none will be fitted.

Aircraft and Unmanned Systems

The flight deck will be of sufficient size to handle large helicopters like Merlin and especially, Chinook. Although not an amphibious assault ship, Chinook compatibility is good for all manner of operations that require heavy lift.

[the_ad id=”53393″]

The main embarked aircraft for the ASW variant will be the Merlin HM2, the ‘airborne frigate’ The Merlin HM2 will normally be carried by the Type 26 although the naval Wildcat and CHF Merlin may also be used depending on requirements. The HM2 version on the Merlin is an incredibly powerful and sophisticated system that is combined with the numerous capabilities of Type 23 to create a formidable team, likely to be transferred to Type 26 GCS.

Merlin can launch the Stingray Lightweight Torpedo and can carry a Minigun or M3M machine gun.

Wildcat helicopters can also be operated from Type 26

Wildcat can launch Stingray and carry GPMG and M3M and will also be able to carry the Sea Venom (replacing Sea Skua) and Martlet missiles. The two-way datalink equipped Sea Venom is for use against small to medium-sized combat vessels and Martlet, small craft and RHIB’s.

Although the Royal Navy has trialled various UAS over the years, none are yet in full service.

Aircraft and Stores Handling

Ship-borne aircraft handling systems are required to capture, move and restrain different types of aircraft in high sea states and adverse weather.

MacTaggart Scott pioneered helicopter recovery systems. The deck lock system requires the pilot to hover over a steel grid in order to deploy the locking ‘harpoon’. Once engaged the hydraulic actuator system, from Claverham, pulls the helicopter onto the deck, compressing the oleo leg in conjunction with negative thrust from the rotor. This system can secure the helicopter to the deck without needing any personnel to approach it, an important safety consideration. The deck lock grid is available from a number of manufacturers and is widely used.

Additional securing straps are often used and the deck lock released, it is a flexible system and because the actuator sits on the centre of rotation the helicopter can be easily manoeuvred into the most favourable position for subsequent takeoff. The pilot has immediate confirmation that the helicopter is secure and is not reliant on others

Once secured to the deck, a means of transporting to the hangar is required and these fall into two broad types, rail assist and tug.

The MacTaggart Scott TRIGON system is used by many operators and makes use of computer-controlled steel wire ropes to secure and move helicopters.

It uses a series of cables, with the three rail PRISM system specifically on Type 23 for Merlin, this document makes a good case for the all-round superiority of TRIGON.

Any future rotary RPAS will need to be able to launch and recover in high sea states so securing and moving in high sea states will be of great importance. Although no details have been released specifically for Type 26 GCS aircraft securing and handling it is likely to make use of designs already in service.

For Type 26 GCS, the Air Weapons Handling System (AWHS) will be designed by Babcock

The system will store and move air weapons from their storage locations to weapon preparation areas prior to transfer onto aircraft or into torpedo launch systems. Re-stowage of unused munitions is also part of system operation and a high degree of automation will reduce manual handling.

Inside the hangar, an overhead gantry crane will be supplied by Marine Systems Technology. Given the route from the flight deck, through the hangar and into the mission bay, this may require a bespoke design. The hangar is sized to accommodate a single Merlin helicopter or two Wildcats.

As can be seen from the image below, there is a pass-through from the hangar to the mission bay.

Future rotary UAV’s may also be housed in the hangar.

Helicopter Landing visual aids and lighting will be supplied by AGI Limited including Homing Beacon Lighting, pilot eye line lights, visual approach lights, control systems and the Advanced Stabilised Glide Slope Indicator (ASGSI)

The flight deck safety net assemblies will likely be provided by Vonroll, as they do for other Royal Navy vessels.

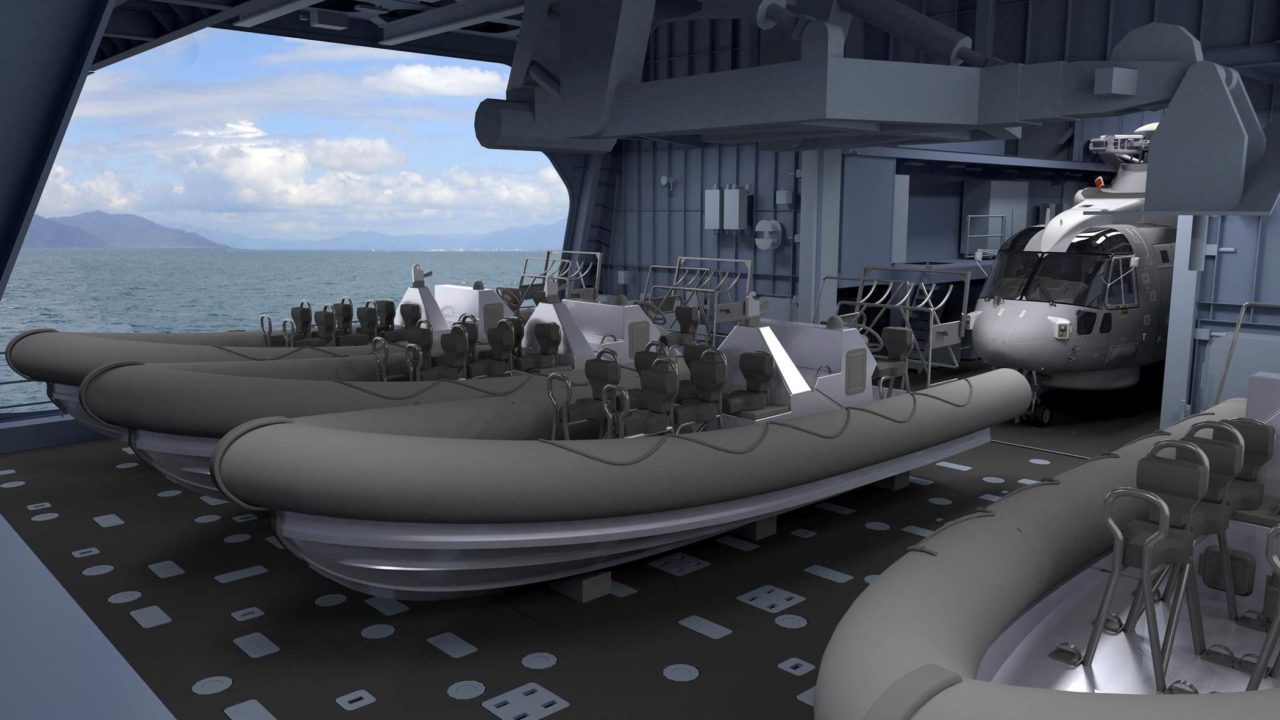

Adaptable Mission Bay

The mission bay is an important part of the concept of operations for Type 26.

Equipment modules, vehicles, boats, UAV/USV’s or stores can be carried from the beginning of deployment or if required, flown, sailed or driven out to a nearby port, and loaded from either side. In the first concept drawings, it was shown as housed underneath the flight deck but as the design matured, moved to a more central position, forward of the helicopter hangar and below the main weather deck.

This arrangement allows modules or other cargo to be landed onto the flight deck and then moved through the hangar to the bay. Although it is assumed the hangar will have some form of overhead gantry crane it is not clear if this crane can extend into the mission bay. If not, equipment may have to be manually handled through the hangar and into the mission bay. The mission bay can accommodate a range of small craft such as Inshore and Offshore Raiding Craft, Sea Boats (up to 12m long) and up to ten 20ft ISO containers. In addition to boats and containers, it can also accommodate a Merlin or even two Wildcat helicopters.

An early image below is from a Babcock investor presentation that showed the mission bay being used to disembark an RHIB.

Combined with the flexible accommodation provision, it opens up some very interesting opportunities. Payload modularity gets a very bad ‘rap’ from the online defence community, driven I suspect, largely from the US Navy LCS woes, but it is a sound concept. It provides a great deal of flexibility but where it differs from other modular approaches (such as the LCS) is that the ships main sensors and weapons are fully integrated.

With Rolls Royce now having a separate section on their website for mission handling. Read more here and a PDF Brochure

The Type 26 GCS project team were also leading on a couple of projects that will benefit NATO standardisation, namely module interfaces and shock protection. A mock-up of the bay was constructed at RNAS Yeovilton to allow experimentation, especially with regard to moving loads inside and outside the bay. The shock protection system was developed by Thornton Tomasetti Defence Ltd, formerly Weidlinger Associates, a British company with its parent in the US. The protection system was designed by TTDL in Scotland, funded by DE&S Naval Authority Group at Abbey Wood. This was tested at an underwater range in Scotland with very encouraging results.

There is much more to this system than meets the eye, it will have active heave compensation and an ability to move loads up to 15 tonnes, with those loads including crewed and uncrewed vessels, ISO containers and other bulk loads. The cradle assembly can be changed as designs evolve.

As can be seen from the images below, it has changed since the earlier design, the one on the right showed a development.

Marine Systems Technology and PAR Marine had been mentioned in relation to the supply of the x-y crane used in the mission bay, the same manufacturer that provides the crane for the US Navy LCS Freedom-class and DDG-1000. Rolls Royce/ODIM has signed a Design and Development Agreement for the Type 26 Mission Bay Handling System, but they will supply the crane used in the helicopter hangar, not the mission bay.

It looks to be an extremely versatile system, with the latest imagery suggesting a slightly different configuration to that shown above.

As the Mine Countermeasures and Hydrographic Capability (MHC) Programme progresses there may also be further work with the crane system to allow it to launch and recover autonomous unmanned systems.

MacTaggart Scott will supply mission bay side doors.

Accommodation

Accommodation is included for 208 crew, with a core complement of 118. The additional crew space could be used for Special Forces, beach recce parties, raiding forces, rescued civilians, UAV operators or other mission specialists.

One would expect that the ‘core complement’ will change depending upon specific deployment requirements but however used, the additional spaces make for a flexible arrangement. One thing is certain, though, whatever the final number they will have much-improved accommodation facilities compared to the Type 23, yes, including iPod charging points! Accommodation spaces will probably be unisex and similar to those found on CVF and Type 45, as supplied by Strongbox Marine

There will no doubt be those that hark back to the good old days of mess decks but modern ships need modern people and modern people need modern accommodation. Those aboard will be deployed for long periods and I find nothing unusual whatsoever with wanting to provide them with as good facilities as reasonably practicable.

Commissariat equipment will be supplied by Kempsafe and the reverse osmosis potable water generation equipment by Salt Separation Services.

Marine Systems Technology will supply the gastight, weathertight and watertight doors, hatches and scuttles, now part of the PAR Group.

Fire Prevention and Control

One of the most significant through-life cost drivers is personnel and although power, propulsion and electronics technology have traditionally required less personnel in successive generations of equipment a barrier to reducing crew numbers overall has been the fire/damage control requirement. The first strategy is to prevent fires in the first place, design and material choices can do a great deal to reduce the potential for fire but warships are dangerous places, filled with dangerous materials. Fire detection systems that will include integration with machinery monitoring systems will allow the early detection of both the potential for fire and fire itself.

Although traditional methods of fire-fighting, suitably trained and equipped members of the crew, will be used, they will be joined by a range of automated systems. One of these new approaches is the use of high-pressure water mist systems. HPWM is said to offer improved fire suppression whilst using dramatically reduced water volume compared to conventional sprinklers. The ultra-fine mist cools, displaces oxygen in the fire (not the whole compartment) and absorbs radiant heat. Unlike conventional water drenching systems it can be used on live electrical fires and because it is not harmful to humans, can be initiated immediately, without waiting for the crew to escape a compartment that might have extinguishing gas systems. The system also has some measure of sophistication, initiating to cool escape routes pre-emptively or drench magazines, for example,

Tyco Fire and Integrated Solutions, Manchester, will provide the fixed firefighting system for the Type 26 Frigate using water, mist, foam and gaseous solutions.

Boats and Mine Countermeasures

Now owned by BAE the VT Halmatic Arctic and Pacific Rigid Inflatable Boats are used by the Royal Navy for general transport tasks and boarding operations, in service since 2004. Powered by a Yanmar marine diesel engine and Hamilton HJ 241 waterjet they have a top speed of approximately 30 knots. Each has a length of 7.8m, a beam of 2.57m, a draft of 0.5m and a hoist weight of 2.5 tonnes. The slightly smaller Pacific 22 MkII is also in service. They are fitted with a range of communication and navigation equipment, use a single Henriksen hook for lifting and lowering.

This type of craft will likely be a standard fit for the Type 26 GCS

One of the potential uses of the mission bay is for supporting deployable mine countermeasures and survey capability. This does not turn a Type 26 GC into a dedicated MCM vessel but it is an area that is currently being developed with the MHC and Sweep programmes. Both these programmes are maturing rapidly, with the Anglo-French Anglo / French Maritime Mine Countermeasures (MCMM) / SLAMF (Système de Lutte Anti-Mines Futur) recently awarded a manufacturing contract for completion in 2022.

In addition to the survey and mine countermeasures roles, unmanned surface vessels may be deployed for force protection and situational awareness.

BAE and ASV have recently demonstrated their unmanned technology.

From BAE and ASV;

Unmanned technology with the potential to change the face of naval operations within a decade has successfully been demonstrated for the first time by BAE Systems in partnership with ASV at a site near Portsmouth Naval Base. The new system will allow crews to carry out vital tasks such as high speed reconnaissance and remote surveillance while keeping sailors out of harm’s way. The modified boat is capable of operating autonomously for up to 12 hours at a time on either a pre-planned route or via remote control. It can reach speeds in excess of 38 knots (44 miles per hour), providing unique ship-launched manoeuvrability and enhanced situational awareness to support the decision-making of its operators. The technology is designed to be fitted to the Rigid Inflatable Boats (RIBs) like those already used extensively by the Royal Navy.

Underpinning the system’s ability to operate autonomously is its complex array of sensors, including a navigation radar, 360 degree panoramic infrared camera array and laser range finder which offer operators a detailed picture within a significant range of the vessel. “This technology delivers an extremely robust and fast-moving unmanned boat that is able to perform a number of surveillance and reconnaissance roles, even when operating at high speed or in choppy water,” said Les Gregory, Product and Training Services Director at BAE Systems.

“BAE Systems has a wealth of experience in the development and integration of unmanned systems. The successful demonstration highlights the enhanced capability this technology offers. While other programmes are primarily designed for larger, slower boats to tackle mine counter-measure scenarios, this system provides an extremely manoeuvrable multi-role vessel.”

The unmanned system and software algorithms controlling the boat were provided by Portchester-based unmanned and autonomous specialist, ASV. BAE Systems has been working closely with ASV to integrate the technology and prove the concept through the demonstrator. The next stage in its development is to create the sensor suite before ensuring a seamless integration with the combat management system on the parent ship.

Dan Hook, Managing Director for ASV said: “The algorithms we’re developing with BAE Systems allow the boat to perform complex missions and navigate through waters avoiding collisions. “This gives it the flexibility and sophistication to operate in a number of different tactical roles, whether it’s patrolling areas of interest, providing surveillance and reconnaissance ahead of manned missions, or protecting larger ships in the fleet.” The boats will be able to operate up to 40km away from their parent ship. As well as being completely autonomous they can also be remote-controlled by crew on land, from the ship via a hand-held controller or piloted as usual.

The technology is designed as a retrofit to the manned Pacific 24 RIB already deployed across Type 23 Frigates and Type 45 Destroyers. These boats will also go on to the Queen Elizabeth Class aircraft carriers once they enter service.

As unmanned technology develops, there is no doubt this kind of system will be carried and operated by Type 26 GCS.

Other

- Raytheon Anschütz Integrated Navigation and Bridge System (INBS) and visual surveillance system

- Rolls Royce Marine, the steering gear, RAS equipment and stabilisers

- Score Marine, valves

- Reynolds Hi-Tec, flexible couplings.

- L3 Marine Systems Platform Management System

- Cathelco(Evac), cathodic protection.

- BAE, EDGE Meteorological and Oceanographic (METOC) system will be from BAE, it collates information from multiple on and off-board systems, providing information for combat and navigation purposes.

- Johnson Controls will supply the chilled water plant

- Detegesa, the membrane sewage treatment plants and oily water separators

- Pellegrini Marine Equipments (MEP), the anchor handling and mooring equipment, boat davit, and radar cross-section screen closures.

- Tod Defence will provide some composite structural components for sonar equipment

- Righton, pipe fittings

- Brüel & Kjær, sound measurement and monitoring equipment

- Whippendell Marine, helicopters starting and servicing equipment

- SPX International, wholeship strainers

- Rolls Royce, replenishment at sea equipment

- PecoFACET, AVCAT filters

- Mackay Consolidated, pipe hanger inserts

- Liferaft Systems Australia, marine evacuation systems

- 3B Pipeline, pipe fittings and materials

- Hutchinson Stop-Choc, wholeship mounts

- Goodwins Steel Casting, shaft brackets

- GEA, diesel fuel and gearbox filtration systems

- Calzoni; hangar and mission bay enclosures

- Ernest West and Beynon, cool rooms

- Sauer Compressors, high and low pressure compressors

- DESMI, pumps

- OSI Maritime Systems, Electronic Chart Precise Integrated Navigation System (ECPINS)

There are many hundreds, if not thousands, of other systems and components, not listed above, CBRN protection, waste management and even the paint for example.

Summary

With all the technology described above, it is easy to forget that the single most important part of Type 26 GCS will be its crew, shore support and other personnel.

What will the Royal Navy get with Type 26 GCS?

Simply, an evolutionary, low risk but extremely capable system that builds on the best of Type 23 and Type 45.

It will be flexible, capable, have bags of growth potential and suited for contemporary operations against peer threats whilst in compliance with the latest standards, norms and expectations, and rightly so.

Despite the rather convoluted development process, I can’t see what is not to like.

Table of Contents

Change Status

| Change Date | Change Record |

| 01/03/2017 | initial issue |

| 14/07/2021 | Update and reformat |