As part of a joint port opening and operating capability in support of military and disaster relief operations, the UK should establish a rapid port survey team, able to deploy at 24 hours notice, with the objective of creating a rapid assessment of port damage, status, and ability to receive marine traffic.

Share on twitter

Twitter

Share on facebook

Facebook

Share on linkedin

LinkedIn

Share on reddit

Reddit

Share on print

Print

The foundation of this whole proposal is marine engineering expertise and experience, which we have plenty of.

There are two phases in which this requirement operates; business as usual and rapid response. Business as usual would include survey, design, contract management and operations support, essentially, spending the FCO’s and MoD’s money on supporting Requirement 1 and 2 and in a standalone capacity where the development of small ports makes sense as part of an overall conflict reduction or defence engagement strategy. It will also have an important skills transfer function, building capability. To be clear, this function would not be designing multi-billion Dollar container hub ports, but it would be doing so at a much smaller scale.

The rapid response element would be in support of military options, or as part of disaster response. The survey task is arguably the most important as it describes a commonly recognised picture of the environment and task at hand, this could be a green-field site or an existing port, most likely the latter. It might at first be imagined that a port survey would simply comprise of a bathymetric survey of approach routes, berths and turning basins but for a port to be of use to a joint force commander or humanitarian response effort, it must include much more.

It is this breadth that makes it a relatively complex task and drives the requirement to involve skills and capabilities across the defence spectrum, and possibly beyond defence as well. The baseline for a port survey is bathymetric and sub-surface obstruction information, but it should also include the following;

- Berthing and mooring facilities; are they damaged, are they in a good enough condition for shipping and what augmentation or repair is needed

- RORO link-spans, ramps and slipways; are they damaged, are any present, can they support the required traffic levels and shipping types

- Aids to navigation; are they present, in the right place and in what condition, can they support safe navigation for military and civilian shipping

- Handling equipment; cranes, reach stacker’s, forklift trucks and port tractors could all contribute to cargo handling but are they in a serviceable and safe condition, what spares or repairs do they need and how many of each are present

- People; harbour pilots, stevedores, security and engineers are all essential and will be needed to supplement military or aid agency personnel, does the port have a functioning team of people, can they be re-employed if not and is it possible to employ additional local staff

- Warehousing and storage facilities; hard standing, buildings, refrigerated storage and fuel tanks (with their associated pipelines and pumps) allow ships to be cycled through the port quickly, their condition and capacity will form part of the planning calculations

- Access roads; if stores are to move beyond the port the surrounding access roads will need to be assessed

- Others; utilities, security, lighting, radio systems and helicopter access are additional survey requirements

There might be many moving parts in play, emerging needs, changing situations and information that may be incomplete. The simple objective is to create an accurate, georeferenced survey of the port, its facilities and potential for operability at a scale required by operational need.

With a survey complete, either using resources within the survey team or using ‘reach-back to the non-deployed team, an agreed design would be completed. A gap analysis between the ‘As Found’ state and requirements of the joint commander creates a statement of requirements for build, repair, augmentations and/or operation would also inform the design.

The agreed design and resultant work packages could either be fulfilled by resources organic to Requirement 2, or using local or international contractors on a less time-sensitive basis. Management of work package fulfilment could again use a combination of organic or contractor resources, depending on requirements and timelines.

Able to quickly deploy and into hazardous environments, the survey function would be the lead element for Requirement 2, and possibly requirement 3. One aspect that can have an achievable time requirement is a notice to move for the survey team in response to an urgent requirement. Holding the small survey team at 24 Hours-Notice to Move should be sustainable without disproportionate impact. All survey team equipment should be transportable by air, preferably no more than 10 tonnes per individual item for transportability by helicopter.

To meet Requirement 1, the first task is to compare it with existing capabilities, and in this regard, the UK is actually well placed. Where some augmentation will be required is in the rapid response and integrated port survey capability.

Existing Capabilities

Survey

HMS Echo and HMS Enterprise are relatively new vessels and are both equipped with sophisticated sonar systems, seabed sampling and analysis equipment and a small survey launch, Sapphire and Spitfire respectively. In addition to their survey role, they can embark additional personnel in the mine countermeasures command role. Their equipment includes a side scan, multi-beam and single beam sonar, an oceanographic and seabed profiler, bottom sampling equipment and a Doppler current measuring system.

The launches allow survey equipment to be carried into very shallow waters to collect data which is then merged and referenced to complete the complete picture.

Equipment carried on the 9 tonnes 9m long survey launches includes a Kongsberg 2040 Multibeam Echo Sounder and Kongsberg EA400 Single Beam Echo Sounder. The EM2040 is used for high-resolution mapping and inspection in shallow water. For accurate survey work and second layer detection, the EA400 single beam echo sounder is deployed in conjunction with GPS. Sidescan sonar is also used for seabed mapping.

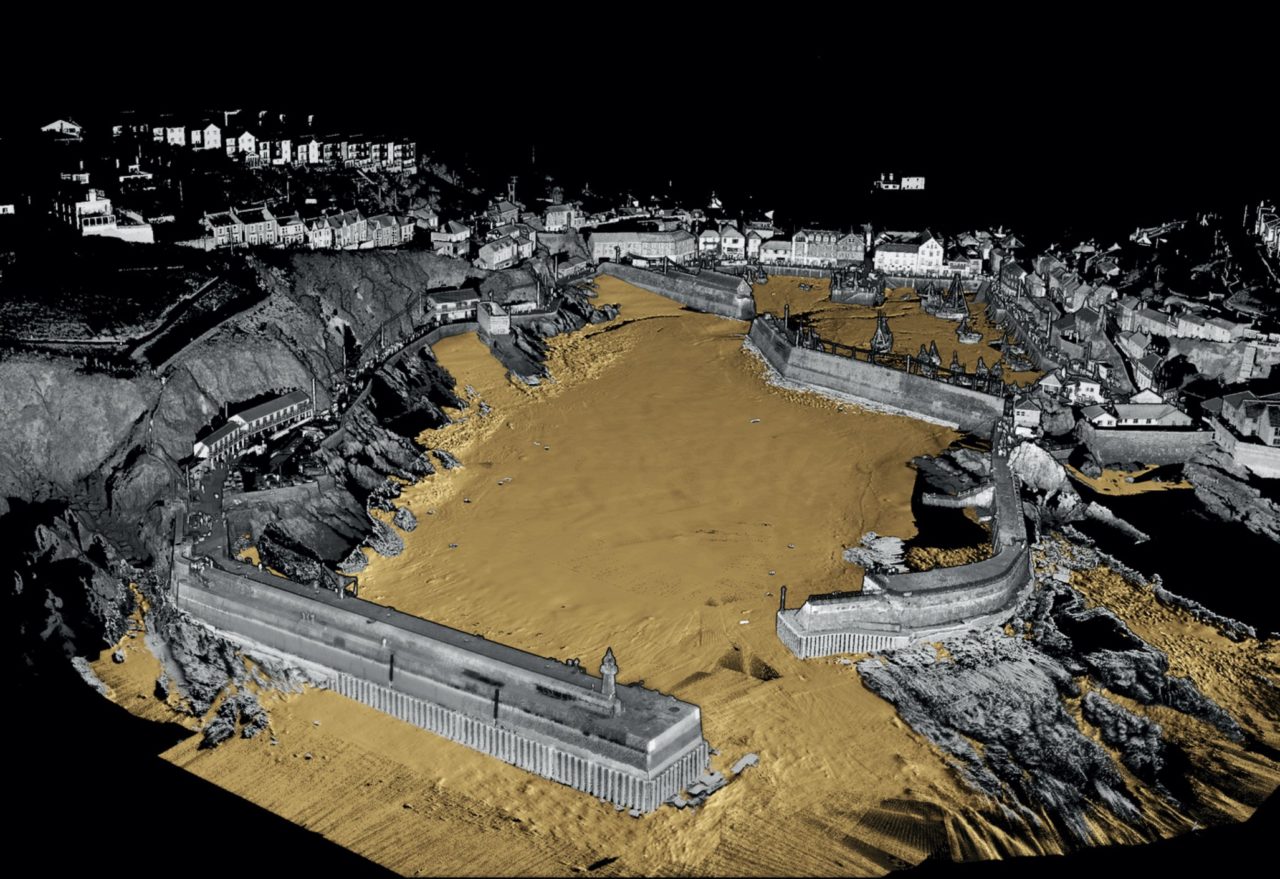

These systems and technologies are combined with RN survey expertise to produce extremely accurate surveys and charts of the seabed and water column. Multibeam, single beam and side-scan sonar is usually used for bathymetry, or depth and relief measurements. Tilting the sensor allows data to be gathered right up to the water surface and the high resolution produces photos like very accurate imagery. A higher frequency scanning sonar is often used for collecting imagery from underwater structures, scour, sediment accumulation and pier damage for example and these are sometimes combined.

The image below shows just such an image of the port of Misrata in Libya.

Produced by the Royal Navy

Thing have moved on significantly since 2011, a decade of systems and skills development

Although this is a fantastic capability, it is not rapidly deployable and requires either Echo or Enterprise to be nearby. It might be possible to devise a trailer for them and hold at readiness but they would be detached from their parent vessel.

The British Army (Royal Engineers) also maintain an extensive GEOINT and survey capability that could be used in a port survey task. The capability is provided by 42 Regiment Royal Engineers as part of the Joint Force Intelligence Group (JFIG), comprising two Geographic Squadrons (13 SQN and 14 SQN) and a Support Squadron (16 SQN), all based at Roy Lines, Wyton. 42 Regiment also includes an Army Reserve Geo squadron, 135 Geographic

As the Royal Navy survey capability, they continue to innovate with new technology like uncrewed systems.

Most ports will already have some information available in the public domain or available in the Additional Military Layers (AML) data set from the UKHO Defence Maritime Geospatial-Intelligence Centre, as ratified by NATO under STANAG 7170, but given the locations of likely target ports, detailed information may not be available, so a rapid environment assessment is the first stage in augmenting any existing information.

AML supports the following information sets;

- Contour Line Bathymetry (CLB)

- Environment, Seabed, and Beach (ESB)

- Large Bottom Objects (LBO)

- Maritime Foundation Facilities (MFF)

- Routes, Areas, and Limits (RAL)

- Small Bottom Objects (SBO)

In addition to AML, the Defence Maritime Geospatial-Intelligence Centre provides Environmental Briefing Dockets (EBD), Strategic Port Products and Beach Intelligence and Survey Database (BISD). Additional material may be available through the wider defence geospatial information and intelligence community. Open source and commercial information can also be comprehensive, the Lloyds List, IHS Fairplay Ports and Terminals Guide or Guide to Port Entry for example. There is no reason why this information could not be exploited.

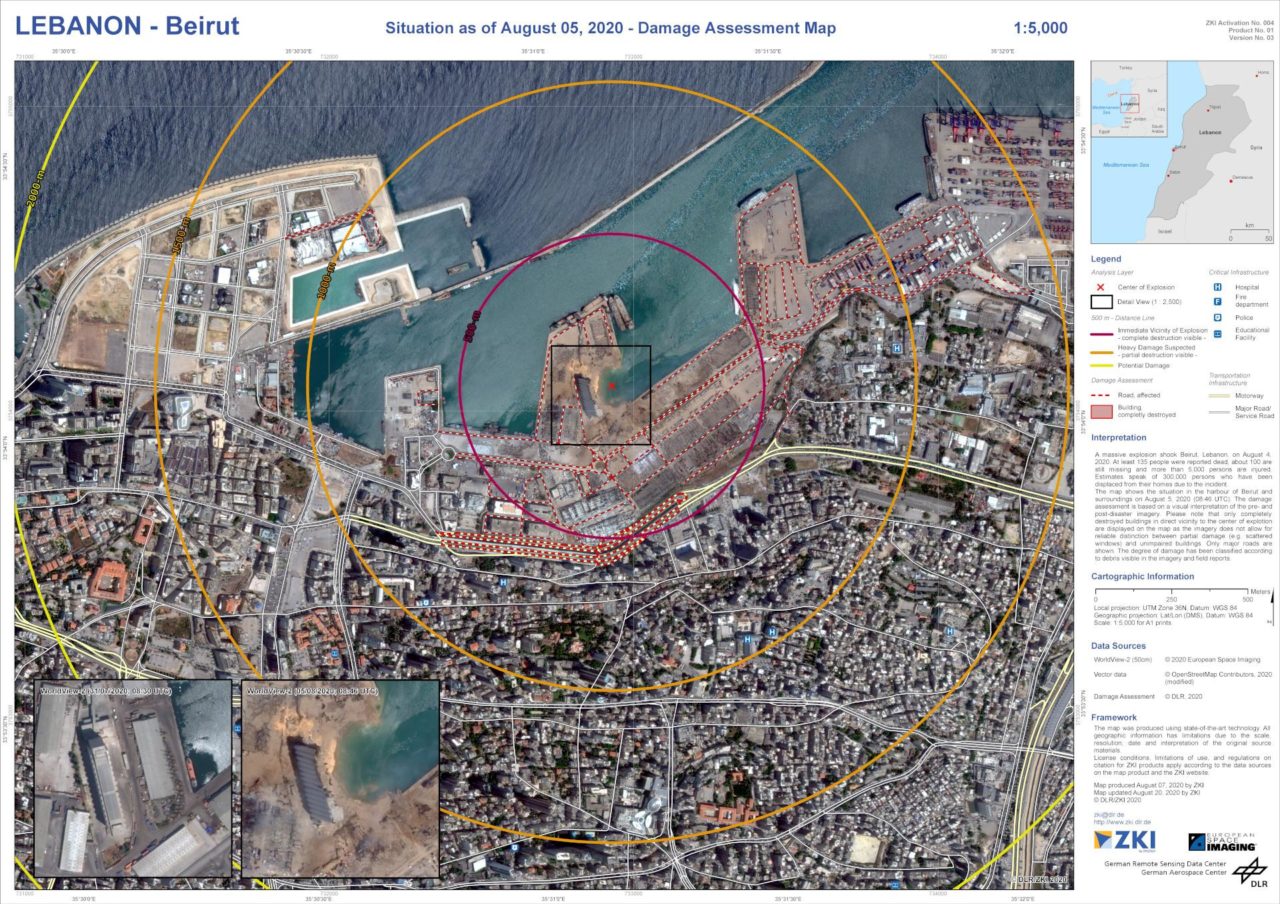

Satellite imagery is now widely available from a number of civilian organisations, often very quickly available, high quality and readily accessible by a number of systems. The explosion at the Port of Beruit in Lebanon was a good case study in just how fast extremely high-resolution imagery could be made available to responders.

Joining the high-quality imagery, synthetic aperture radar analysis also allowed composite maps to be generated that showed damage types and extents.

The Royal Navy and wider defence geospatial intelligence groups have been using this type of commercial satellite product for a number of years and more recently, Airbus has been awarded a year-long contract extension to Airbus for maritime surveillance services.

Drone footage also provided dramatic visuals in 4K, but also, very useful data

A comprehensive picture should be available for most ports and these can be confirmed and expanded using a combination of rapid airborne surveys, physical inspection and local knowledge.

In a large scale disaster relief effort there are numerous agencies and commercial providers that synchronise the provision of this kind of data but in a defence context, it would be likely a NATO or joint force area of responsibility.

The MoD Salvage and Marine Operations (SALMO) team coordinates towing, salvage, heavy lift, operational moorings, port clearance and underwater engineering on behalf of the Royal Navy and other government departments. SALMO is an interesting but little know organisation within the MoD but provides first responder personnel on short notice and a broad span of expertise. Some of its personnel are sponsored reserves. The team is based at Greenock and Devonport, with its HQ at Foxhill, near Bath.

SALMO has recently contracted for a maritime deployable habitable operations ISO container.

Mine Countermeasures and Clearance

Although in many cases, the clearance of mines and IED’s from a port environment will not be required, it must be considered as part of the overall capability. It is also an area where the UK is extremely well resourced, with a range of cutting edge capabilities maintained across the services.

Port facilities, warehouses, cranes, quaysides and harbour walls are easy to mine but difficult to clear. The Royal Navy Fleet Diving Squadron has two Diving Groups, North and South, that provide EOD from the high water mark to the UK territorial limit, on vessels, the RN estate and offshore facilities. The Royal Engineers are responsible for the clearance of WWII German bombs, land mines and military booby traps. Just to make this even more complex, they also deal with service ammunition above the high water mark or non-tidal water (rivers and lakes) except those specifically within the remit of the RN or RLC. The Royal Engineers will also be used where functions like drilling or excavation are required and also provide specialist high-risk search capabilities. The Land Forces EOD and Search Branch was established in 2010 with the aim of providing a single focus for all policy, direction and inspectorate responsibilities The Royal Logistic Corps, because of their expertise with ammunition have generally dealt with the more complex IED’s. Royal Engineer Search team (REST) will also provide an essential element of a port survey clearance operation.

[the_ad id=”53382″]

Port Design and Operating Capabilities

The MoD’s port design and operating expertise reside in 17 Port and Maritime Regiment RLC, 165 Port and Maritime Regiment RLC, 509 Specialist Team Royal Engineers (STRE) and the less well-known Engineer and Logistics Staff Corps, part of 77 Brigade. The Regiment consists of two Port Squadrons (51 (Work Boat) and 52 (Mexeflote)), a Port Enabling and Headquarters Squadron (53), and an attached REME Workshop.

It operates a wide variety of vehicles, engineering plant, and vessels, including Workboats, Combat Support Boats, the MEXEFLOTE rafts, and Rigid Raider Craft. It also has the only military Dive Team in the RLC, responsible for a range of tasks including port clearance and vessel maintenance.

17 Port and Maritime is paired with an Army Reserve regiment, 165 (Wessex) Port and Enabling Regiment, which has the following; 264 Squadron – HQ, 142 Squadron – Vehicle, 232 Squadron – Port, 265 Squadron – Port, 266 Squadron – Port and 710 Squadron – Operational Hygiene

170 (Infrastructure Support) Engineer Group is responsible for infrastructure delivery and has a number of Works Groups.

- 20 Works Group (air support)

- 62 Works Group (water)

- 63 Works Group (electrical power and engineering works)

- 64 Works Group (fuel)

- 65 Works Group (civilian infrastructure, road and rail)

- 66 Works Group (geotechnical, testing and air support)

509 Specialist Team Royal Engineers (STRE) is an Army Reserve unit that specialises in Port Infrastructure.

A good example of their capability is relevant to this proposal, a port survey for the Government of Anguilla in the Caribbean in 2014.

Two personnel from 509 STRE conducted a detailed survey of the Road Bay jetty. From the MoD;

Road Bay is the only port of Anguilla. It is the port at which RN and RFA Ships anchor when visiting the island. There is one sole jetty in the harbour and it required a complete structural survey in order that it can be deemed fit for purpose. Anguilla lacks the professional expertise to undertake the task and asked if the MOD could assist, rather than having to tender out the task to an external commercial company.

The original jetty at Road Bay was built out of timber during the late 1960s by 33 Field Squadron Royal Engineers following the Anguillan revolution and the split from St Kitts. The current concrete structure was built in 1978 and extended in 1986 when a concrete jetty link was also added, replacing the original timber structure. It has previously been inspected in late 2002 and some repairs were carried out as a result of that inspection. Early on Sunday 3rd March 2014, Warrant Officer Class 2 Carl Green and myself, Major Andy Nixon MBE both from 509 STRE (Port Infra), boarded a plane at London Gatwick Airport to Antigua en-route to the island of Anguilla to carry out the structural survey. On arrival, we were met by Mr Bancroft Battick, the Chief Engineer at the Ministry of Infrastructure for the Government of Anguilla, who was to be the host throughout the trip, which was planned to last 5 days.

The survey required both surface and sub-surface inspections of the jetty, which in turn meant much of the task was spent either below water or underneath the jetty structure. It quickly became obvious that the jetty has had a hard life, with significant damage caused by impacts from ships and over loading of the structure with significant delamination of the concrete caused by corrosion of the steel reinforcement where the structural members have been overstressed and cracked, allowing ingress of sea water. Damage to the structure is evident throughout and a significant amount of urgent repairs are needed in order to extend the life of the jetty.

After submitting a detailed report, development consultancy was provided by DLN Consultants International in Barbados and in May 2016, HMG approved an EC$4m loan for completing a full set of repairs. The detailed survey can be found at this link. Across the wider group, there is expertise in design, construction, technical consultancy in a wide group of specialisms, technical reconnaissance, contract management, accredited materials testing and project management. The breadth and depth of expertise in 170 is significant, and wholly relevant to this proposal.

The final part of the expertise jigsaw is the Engineer and Logistic Staff Corps (E&LSC), a network of senior civilian engineers. E&LSC is a little-known organisation comprising senior executives of sixty British logistics and engineering organisations that retain military rank but have no military duties or pay. They exist purely to provide expert advice, often characterised as ‘all rank and no file’ Members of the E&LSC were involved with planning and delivery of the RORO linkspan used in Kuwait in 2003 as part of force build prior to operations in Iraq, members are drawn from a wide range of British commercial organisations.

Establishing a Port Survey, Design and Operate Capability

What should be clear from above is that the capability exists, but it is spread across the Royal Navy, Royal Logistic Corps, 77th Brigade, the Royal Engineers and a couple of MoD/civilian organisations, Defence Geographic Centre for example. Not only is the capability and expertise distributed across the defence organisation, it is also distributed in geography; the DGC is in RAF Wyton, RN Survey at Devonport, 17 port and Maritime in Southampton and 509 STRE in Chilwell, near Nottingham. And, that is before we look at EOD and MCM.

Some of the capabilities, specifically 509 STRE, are Army Reserve, which means the rapid response to short term requirements and continuous deployment for building capacity overseas may be constrained.

To remind you, Requirement 1 has two components;

- Ongoing port survey, design, contract management and operations support to underpin building capacity overseas activities,

- Rapid response port survey at 24 hours notice to move in support of contingent military operations and disaster response.

Without a mass of personnel, it would be impossible to deliver against any of the objectives and so the first part of the proposal is a simple one. By establishing a full-time team of port survey and design engineers, with attendant back office support, the critical mass around which means of meeting subsequent requirements can coalesce. The team would essentially operate in two modes; Business as Usual, and Response.

In BAU, the team would operate in response to a planned series of port development programmes and to a defined project plan. It is unlikely that significant force protection would be required, or that IED/mine clearance would feature. The size and composition of this BAU team would be dependent upon many factors, mostly money, but it should be large enough to sustain a response team on 24 hours notice to move, which dictates a base number. The base number is dependent upon the size of the survey team, the larger the survey team, the larger the base number from which it is drawn. Factor in training, leave, career change and other factors and this base number can grow more than might be expected.

One means of reducing its size would be to make extensive use of ‘reach back’, where raw data is transmitted back to the UK in real-time as the survey progresses and is then processed in the UK for subsequent analysis and report generation.

Because the capability looks at the whole port and its nearshore environment, the survey team must comprise a mix of skills. Being able to conduct an underwater survey in the port and its approaches and a condition survey of port equipment and aerial mapping, to name but three, requires skills that are found in multiple services and organisations; divers, hydrographers, cartographers, civil engineers, communication specialists and electrical engineers are not usually found in one place. Which, points to a joint organisation, and where appropriate, that joint organisation could include civilian, FTRS, regular and reserve personnel.

Chillwell, where 509 STRE are based, Southampton for 17 Port and Maritime, Devonport for the RN survey element or even the Defence Geographic Centre at RAF Wyton. A case could even be made for the team to be based near Brize Norton to reduce deployment times for rapid deployability. Availability of suitable space and proximity to the bulk of the required skills would be a factor. Would the team be inside the MoD organisational structure or DFiD, would it be predominantly civilian or military, and if it was in the MoD, would it be an RE or RLC unit?

All these would need to be decided but the simple matter is, building the capability would require a very high level of inter-service and departmental cooperation.

To conduct a detailed port survey the team will need to be equipped for a range of scenarios.

The scenarios are many, but can be loosely grouped into three categories;

- A damaged or austere port with no risk or IED’s, mines or attacks e.g. Port au Prince in Haiti 2010 or Beruit

- A damaged or austere port with a risk or IED’s, mines or attacks e.g. Umm Qasr 2003.

- A well-found port with no risk or IED’s, mines or attacks e.g. Kuwait in 2003

They may also be conducted across a range of timeliness requirements. In a deliberate operation, one of the Royal Navy Echo class survey vessels may well host the survey team, and deploy its survey motorboat. In the rapidly deployed scenario, the ship would not be available and therefore an air deployed capability is needed.

Operating in the context of a wider operation, the survey team would benefit from in theatre transport, force protection and logistic support. This means rapid deployability of the survey team and their supportability becomes less of a concern because they are already in theatre. With this in mind, and putting aside the potential for clearance operations and extensive force protection, the basic transport and equipment requirements of a deployable port survey team become clearer, regardless of whether they are operating as part of a rapid response HADR mission, or a less timely mission to enable the theatre entry of an Army Brigade.

The mode of transport may vary, and the supporting force likewise, but the survey function remains relatively constant, in that, the team must;

- With its equipment, be self-sustaining for 72 hours minimum.

- Able to be transported to theatre in a single C-17 lift or two A400M’s lifts

- Able to drive to the port from a suitable airport

- Equipment must be demountable from vehicles and able to operate from ships of opportunity or utilise in theatre transport

Above Ground Survey

Before deploying the survey team would extract information from existing sources; satellite imagery, Admiralty Charts and commercial information. A rapid airborne survey of a port environment could easily be completed using any one of the many commercial uncrewed systems now available at low cost. A market leader is senseFly able to produce hyper-accurate geo-referenced digital imagery in hours and days.

This video is a few years old now, imagine how much things have changed since.

The post-flight analysis is carried out to add reference points, ground information and stitch the imagery together into an ortho-mosaic image. It can then be exported in a number of formats suitable for inclusion in mapping and GIS systems, whether they be publically accessible through a UN On-Site Operations Coordination Centre (OSOCC) or defence only.

This kind of rapid assessment and mapping system is probably enough for an initial survey, allowing the team to create an accurate map of the port facilities, list buildings and equipment, evaluate routes and estimate capacities. Additional information can be obtained by traditional surveying techniques and laser scanning to create accurate 3D models, should that be needed. For damage assessment, digital mapping tools can also be used to estimate debris volume.

The next stage would be to assess the underwater, on water and the built environment.

Detailed Survey

The underwater environment includes berth areas, turning circles and approach lanes, a hydrographic survey is therefore high on the list of requirements. Under keel clearances, floating and sunken debris, and declared depths are important factors in determining whether a vessel can use the port; vessel squat, manoeuvring characteristics, the accuracy of tidal ranges, sea state and rate of siltation will also need to be understood. S-57, the relevant standard, requires uncertainty to be quantified in ‘Zones of Confidence’

If the Royal navy Echo class hydrographic vessels are available then the standalone survey team would simply concentrate on other aspects of the survey, but in a disaster or rapid response scenario, they would be on their own and have to produce the underwater survey.

Tide gauges will be used to confirm tidal information, this is important to establish declared depth ranges at different times of the day. Valeport and RS Aqua are two UK manufacturers that can supply internally powered data logging gauges.

They can be easily fitted using standard hand tools.

To obtain bathymetric data the traditional approach is to use a small motor vessel of some kind but advances in sonar, LIDAR and uncrewed technologies have allowed much of this to be both automated, and integrated with above surface positional data.

This is now a thriving market and uncrewed vessels for the harbour of coastal surveys are becoming the norm. Apart from the usual defence primes, one company in Cornwall is notable, blurring the demarcation point between above and below waterline survey, integrating single beam, multibeam, side-scan, sub-bottom profiling, LIDAR, photogrammetry and doppler current profilers into modular USV’s like the Inception Class.

They are also developing a larger class of USV, although as can be seen from the image below, still very compact.

This video from Norbit Systems provides a good overview of a similar system, but pole-mounted for potential use as a backup.

Ultrabeam Hydrographic, located on the same business park has recently been awarded an MoD development contract for the ‘mind the gap’ project, surveying wet gap crossing for the Royal Engineers. It is certainly possible to see this being developed for beach and harbour surveys, although sea-keeping ability might limit its applicability for surveying harbour approaches.

Handheld sonars and cameras could also be used to enhance the overall picture, together with remotely operated vehicles (ROV) for specific tasks.

The kind of built environment survey required does not include a full and detailed survey but is more of a condition survey; can warehouses support expected cargo volumes, are they safe, can they be secured, can they accommodate chilled or perishable items. Photography and distance measuring tools, coupled with the aerial survey tools should be sufficient.

Berthing and mooring equipment conditions and RORO ramp facilities would be subject to a visual inspection. Of greater criticality would the condition and strength of mooring piles, and those supporting wharves and jetties. For the latter, dive equipment would be needed.

One of the observations from the Haiti case response was the need to operate in an environment that contained sewage, petrochemicals and other unpleasant pollutants. Protective equipment is available and should be included as required. The ‘Dirty Harry’ system from Divex is a good example, a complete system designed specifically for diving in contaminated waters.

Completing the survey task would be an assessment of aids to navigation, port lighting, stores handling equipment (fixed and mobile) and an assessment of the capability and capacity of the local workforce. The team will need to conduct a physical inspection of the plant, equipment and facilities and wherever possible, conduct this in conjunction with the local personnel, for it is they that will have intimate knowledge that should not be discounted.

Although I have not discussed this a great deal the need for a common and cohesive ‘picture’ of the port, its facilities and environs is one of the most important parts of the survey process. Having isolated pieces of data will result in a wasted effort so workflow, IT systems and data capture equipment is an important part of the equipment requirement. Satellite communication equipment would allow the team to start sending survey data back to the UK as soon as they start, the reach-back process is an important part of exploiting UK based expertise and facilities.

Boats and Vehicles

None of the equipment described above needs to be permanently mounted on anything, but it does need to be transported to the port and moved around within it. The team will also need life support and a working environment that is self-sufficient. The transportability requirement also needs careful consideration when selecting vehicles and boats. Everything needs to be deployed in a single C-17 or maybe a pair of A400M’s.

Although much of the survey tasks could be carried out using USV’s, some would require manual inspection, so a workboat of some kind becomes essential. In-service equipment might be used, but a workboat like the Combat Support Boat and trailer, but with the trailer, weighs over 11 tonnes and needs a large vehicle to tow it. It is also 10m long.

Inflatable craft like the Zodiac FC470 Inflatable Raiding Craft MkIII or Avon WS525 inflatable craft used by the mine countermeasures force could also be used. Above all though, transportability and ease of launch and recovery are the main limiting factors. Launch and recovery via a slipway ramp or beach may not be possible and so launch over the quayside using a hydraulic jib or crane may be the only viable method.

An HDPE workboat like the Pioner Multi is light and robust, has a drop-down ramp for easy diver access and can be launched using a lightweight trailer. Not as powerful or capable as a Combat Support Boat would require only a light vehicle to transport it, not a large truck.

They weigh 470 kg and are 2.15m wide by 5.3m long

About the same size would be something like the Lamor Seahunter.

They can be clipped together to create larger boats and are easily stacked.

An interesting alternative to using a conventional workboat and trailer would be an amphibious vehicle. The reason an amphibious vehicle is worth considering is to maximise space inside the C-17 and avoid the need for a trailer to launch and recover the workboat on a beach or slipway.

The CTruck Avenger amphibious rescue and survey vehicle, Searoader Amphitruck and Gibbs Phibian. The Sea Legs concept is also worthy of consideration, although the workboat would still need transporting via vehicle for any appreciable distance it would negate the need for a trailer. The technology has been licenced to a number of builders including Stabicraft and ReconCraft.

One of the key attributes of these smaller workboats (or amphibious vehicles) is their relatively narrow beam, less than 2.5m. It is this narrow beam that is so critical for carriage inside the C17 because it allows a second payload to be carried side by side, in this case, another set of vehicles.

The workboat and USV may be launched by three methods; concrete slipway or ramp at the port, a beach within sailing distance, or using a crane to lift it in from a quayside. Using something like the CTruk Avenger would provide the most flexibility for launch and recovery but a crane or jib would still be useful.

One of the challenges for launch and recovery would be in areas that do not have suitable slipways for trailer or hand launching. Where the distance between the launch point and water surface is significant (as images below), a conventional hydraulic jib crane might have problems.

A wire rope crane would overcome this challenge, either truck mounted or container mounted.

It could also be possible to use the more compact articulating jib crane with a remote control chain hoise to overcome any distance to the water surface issues. What makes this a relatively easy problem to solve is the low weights involved, less than a tonne for any of the options detailed above, but it would have to have a good outreach in order to accommodate the space used for stabilising outriggers and be under the 3.5m (approximate) height limit for C-17 and A400M carriage.

C-17’s can routinely carry light vehicles like the HUMVEE, Foxhound and other light trucks in a side by side load plan, as long as the vehicle is no wider than 2.4m

Although the C-17 cargo deck is approximately 5.5m wide this does not mean that two vehicles of 2.25m wide can be carried side by side. There has to be space to actually drive the vehicles in and for securing chains to be fitted. Vehicle width is therefore very important for the objective of maximising the available space.

Vehicle selection is influenced by any number of factors; volume and weight of stores, number of personnel, dimensions and weights, suitability for towing and crane mounting, protection levels, mobility requirements and support arrangements to name but a few. It would be preferable to use an in-service vehicle from a support and training perspective but for such a niche role as this, alternatives might offer a better outcome.

If we accept this role will be used in relatively benign conditions, protection may be traded away for deployability and cost. Although a port environment might not be well found, the likelihood is it will have firm surfaces to operate from, and so high levels of offroad mobility may not be needed.

Pinzgauers, Duros, MAN SV trucks and Land Rovers all spring to mind as suitable vehicles but as a thought exercise, a number of light commercial vehicle options can also be considered; pickup trucks, vans and light trucks. Much would depend on the types and numbers of workboats or survey USV’s selected. Trailers limit mobility so should generally be avoided but for a slipway launch, there is no alternative. However, a single launch trailer could be carried as a truckload rather than towed in order to improve mobility.

A Unimog light truck or tool carrier would be a good option if high levels of mobility were required.

The Unimog is available in two major variants, the implement (or tool) carrier and the all-terrain, each having a number of models and options. The implement carrier can be fitted with numerous attachments for many different industries and the all-terrain is optimised for load carriage in difficult terrain.

For towing and launching/recovering the workboat, either would be suitable.

They have both been used with box bodies and trailers and are easily transported by C-130, C-17 and A400M aircraft.

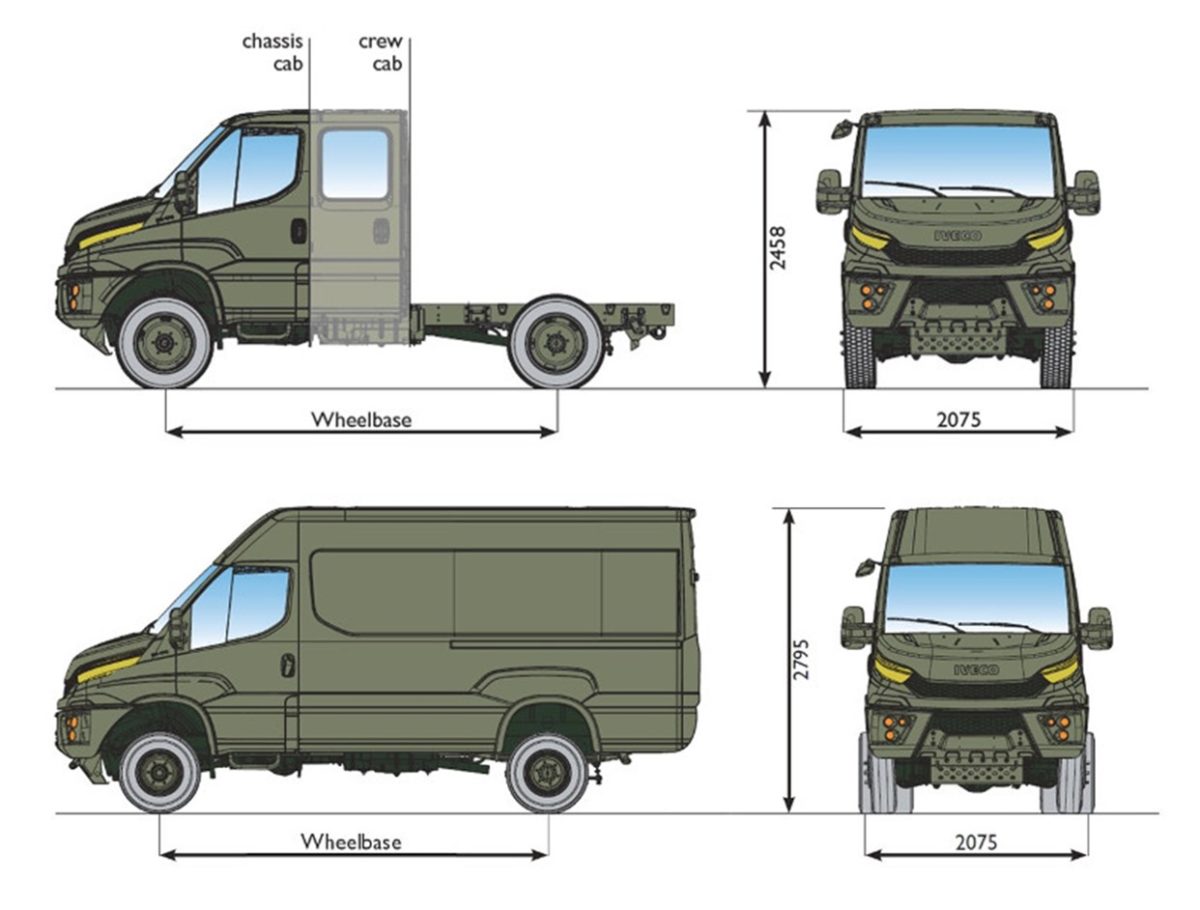

The Iveco Daily 4×4 would provide a good alternative at a very low cost. Like the Unimog, they are available in a range of wheelbase and maximum weights and have good offroad performance. They are also available as a cab, crew cab, van and minibus configuration. Iveco Defence also markets them to the defence sector as the Military Utility Vehicle (MUV).

Aftermarket integrators have added tipping bodies, cranes, hooklifts and other equipment.

Coachbuilders and expedition vehicle builders have also used the Daily 4×4 chassis to create more specialist variants.

Each vehicle would need air conditioning, heating and other modifications to make them suitable for use in a waterside environment in either very hot or very cold conditions. Additional stores carried would include fuel, water and rations for at least 72 hours, spares and tools, shelter, USV,s workboat, survey RPAS, computing and communications equipment, diver support and medical supplies. Rather than just put everything on the back of a van, it might be advantageous to integrate command, control and computing environments into a dedicated shelter,

One option for shelter and a working environment would be to simply throw a 12×12 tent and some folding tables onto the back but in extremes of climate this might not create an optimal environment for the survey team to work, so a demountable ‘command post’ container could be used. Using a demountable container would allow it to be offloaded and the vehicle used for other purposes during the survey.

Because the container would not need to be continually loaded and offloaded a hydraulic system would not be needed although a hydraulic jib would be fitted to the vehicle with the survey boat and could be used. The other method of offloading the command shelter would be to use a Haacon system.

Fitted to the side of the container would be a ‘lean to’ shelter that could provide additional space, or, the shelter could be extendable. There are also many options for air beam or rigid frame soft-skinned shelters (tents to you and me).

Communications in the local area between teams would be delivered by VHF radios and for reach-back communications, especially data transfer, a compact satellite system could be used. There are many available in service and commercially.

Putting this together results in a 4 vehicle, 6 to 12 person package

The requirements set out below are modular, there may be no requirement for certain of the component parts, each one is a ‘mix and match’ based on needs. Ports may be austere, well found, or all points between, and therefore, the scale of effort for each one will also be based on needs.

Table of Contents

Change Status

| Change Date | Change Record |

| 30/05/2017 | Initial issue |

| 26/06/2021 | Refresh and change in page structure |