In the previous post, I looked at the importance of terminology and medical doctrine, and showed a handful of examples of hospital ships in service around the world.

For the UK specifically, and although technically not a hospital ship, RFA Argus is the afloat Primary Casualty Receiving Facility (PCRF), a Role 3 capability.

As of today, RFA Argus will remain in service past 2030, and the capability, if not the ship, will be replaced by the Multi Role Support Ship (MRSS).

Because MRSS is still in concept stage, there is not a great deal of detail on what it might look like beyond manufacturers positioning their designs.

Given there appears little appetite for a hospital ship proper, and the Role PCRF is currently likely to be distributed on MRSS, there is not all that much to discuss.

Only joking!

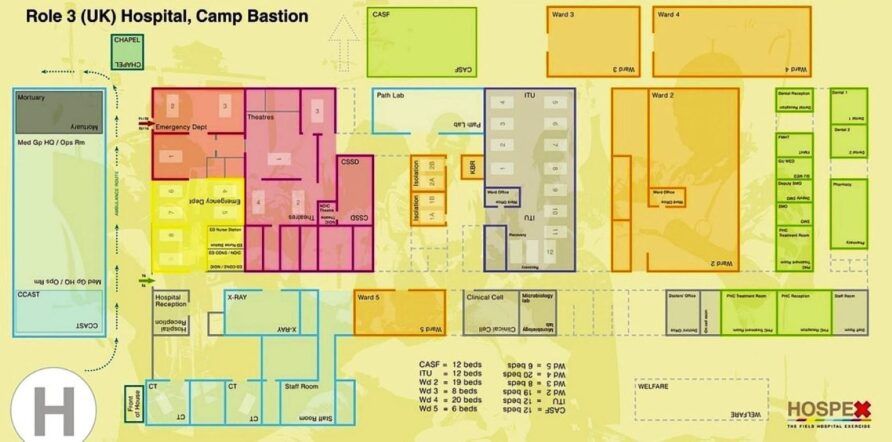

Role 3 facilities required include resuscitation, operating theatre, intensive care wards, advanced diagnostics (X-ray, MRI etc), recovery wards, sterilisation, pharmacy, hyperbaric facilities, and blood/blood component storage.

Medical waste disposal, command and control, laboratory, dental, isolation, medical gas handling, power generation, uninterruptible power supplies, storage space, and catering.

Medical gas handling is more of a challenge than many imagine.

Mortuary, laundry, extensive communications for telemedicine and a computing environment that supports the secure generation, storage, and processing of large volumes of data.

As telemedicine, and even robotics, mature, a Role 3 will likely consume much more power and data, and need additional technical support staff.

I don’t know whether spreading this across multiple MRSS would be optimal.

We live in an age where medical facilities are no longer sacrosanct it seems, and maybe the age of the big medical ship in a defence context is over.

Designing all of the above is far more complicated than putting together parts, patient routes, especially, are important. These should be considered for bringing patients onboard, and emergency evacuation to lifeboats.

The Role 3 at Bastion was on a single layer, approximately 120m × 60m.

Bigger is better.

And custom designed is better, not a conversion.

The Role 3 Conundrum

Arguably the biggest issue for a Role 3 capability is it is not actually used that often.

In a crowded equipment plan and a world of finite budgets, many see them as somewhat of a luxury (even though they are not)

This is perhaps one of the reasons why RFA Argus has endured, she can do plenty of other things, aviation training, disaster relief, and general support to operations.

If we are looking to the future, any Role 3 capability must have some ability to slot into a wider set of capabilities, hence the MR of MRSS.

This is not an easy challenge to resolve because it means accepting compromise.

The other elephant in the room is finding the couple of hundred medical personnel to crew the facility, can increasing telemedicine, robotics, and reach back to the UK reduce that?

Finally, is a Role 3 needed for non land focussed deployments, it seems so to me, but we don’t often see RFA Argus deployed as part of an expeditionary strike package, another one to discuss perhaps?

A Blast from the Past

In response to an established requirement for afloat maintenance and repair, that provided by RFA Diligence, BMT published a study that examined various options for then Operational Maintenance and Repair (OMAR) requirement.

Although RFA Diligence was subsequently withdrawn with no direct replacement, the study did have one component that is relevant to the hospital ship/PCRF conundrum.

That is, a non-propelled barge that could be carried by a heavy lift vessel.

The study suggested using a FLOFLO vessel of opportunity or one on a long-term charter.

The barge was 120m × 32m, with an accommodation block at one end, and a workshop at the other.

Cranes and storage in the middle.

Click here to read the paper.

The concluded

Alternatively, the use of heavy lift FLO-FLO style vessels offers a number of significant features that could make the next generation of repair and maintenance platforms more flexible and capable

This set my thinking for a Role 3 on the same path as the OMAR barge.

Proposal

My proposal is…

- Build a Role 3 afloat facility as a purpose designed module that can be carried onboard a heavy lift ship when needed. The module would be stored onshore and used as a teaching facility for the Defence Medical Services when not deployed.

- The Heavy Lift ship would form part of a future evolution of the Strategic RORO service as established today, crewed by sponsored reserves rather than RFA personnel

Role 3 Module

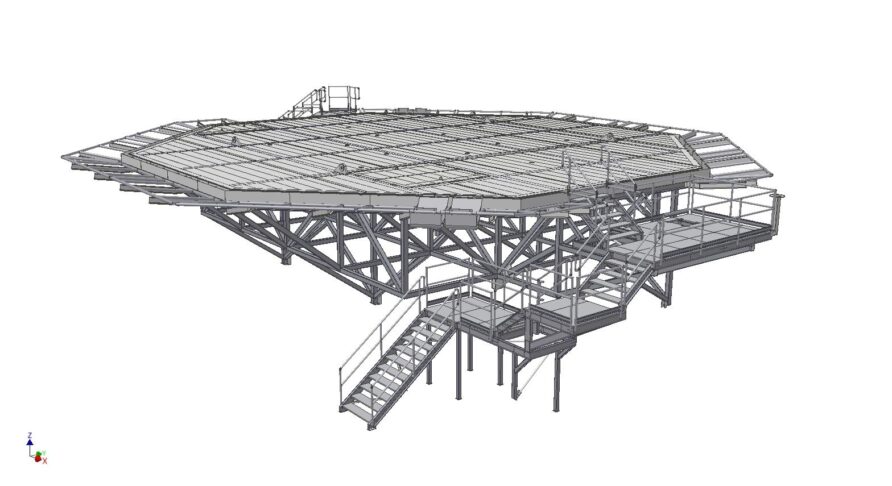

In the offshore sector, there are many examples of accommodation and service modules or barges at a similar scale. It is not an exotic technology.

The images below show examples of self-contained accommodation barges,

The final of the three images above shows a design that is 100m × 30m, with accommodation for 300 personnel, the middle is the Bibby Pioneer, capacity of 200 personnel, similar in capacity to the first, the Nunce.

These are just examples to demonstrate the concept.

Another option might be to approach this as a topside module, the type commonly used in the energy sector, production, or accommodation.

These do not float, but are usually craned onto offshore platforms.

There are pros and cons for each approach, a barge can be carried or towed, but a module must be carried. Barges must be maintained as ships, and subject to certification and inspection regimes.

On many accommodation modules and barges, this type of helicopter deck is common.

But it is unsuitable for a medical facility as the pathway from the helicopter (by which the majority of casualties will arrive) to treatment facilities needs to be as direct as possible, especially for wheeled stretchers, wheelchairs and similar.

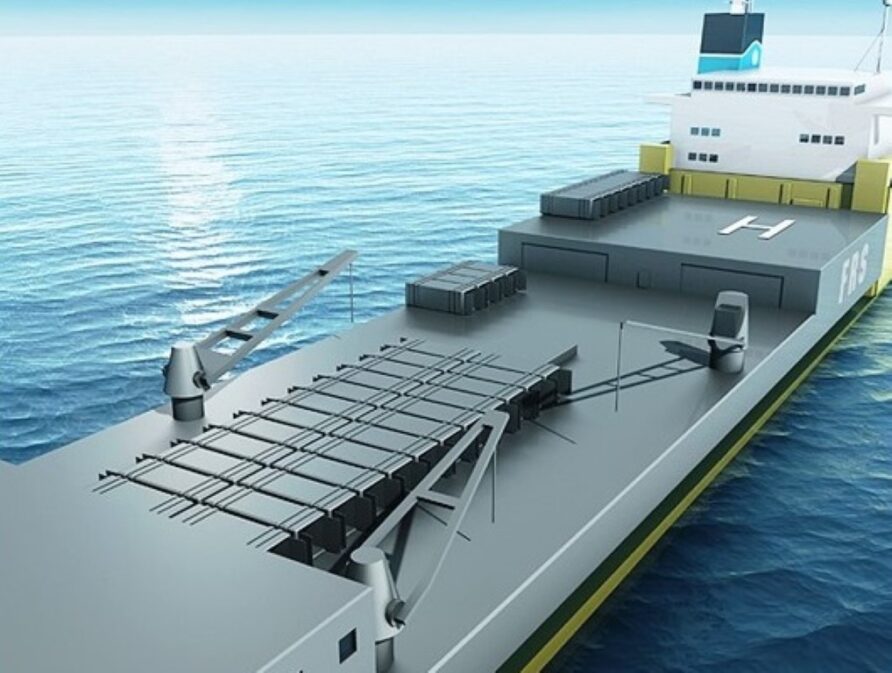

In the barge images above, the working deck has a large crane and other equipment that would not be needed. The deck, in the Role 3 module, would be cleared and used as a large helicopter landing area, suitable for Chinook size helicopters.

The casualty receiving facilities could be at the same level, no lifts, no ramps, straight off the helicopters and into emergency care.

Any landing area should also be towards the stern of the module, with an unimpeded approach path, the same basic configuration as all aviation capable vessels.

By using either a barge or module, the design can be optimised for patient care, not shoe horned into a vessel that has to do many other things, or designed and built around the constraints of an existing vessel.

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Heavy Lift Ship

Assuming using a tug to tow a barge to the operational area is discounted on practicality concerns, there are several options for moving the barge/module.

Examples

Lift On Lift Off

The ship has a large open deck area onto which outsize and extremely heavy cargos are lifted on and off using dockside or integral cranes.

Shoreside cranes tend to be used less than those onboard heavy lift ships, although some ships such as that below don’t have their own cranes.

Roll On Roll Off

The payload is moved on-board using multi-wheeled heavy lift platforms called Self Propelled Modular Transporters (SPMT).

Ballasting allows a straight path to be established between the ship deck and the loading area.

One onboard, the SPTMs are lowered, allowing the payload to rest on the ship’s deck or a specially designed cradle. The SPTMs are then driven off.

Float On Float Off (FLOFLO)

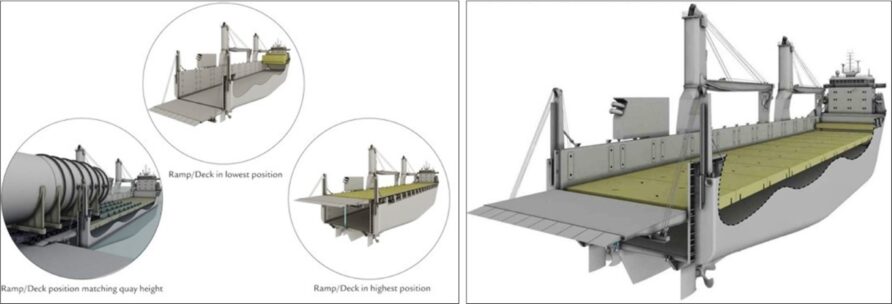

A more specialised heavy lift vessel type is the FLOFLO.

These are semi submersible vessels that are ballasted down such that floating payloads can be (carefully) floated over the deck.

The vessel is then slowly raised underneath the payload, again, sometimes onto cradles.

This method is more commonly used for moving ships, submarines, yachts and other vessels.

Or even Zeppelins.

FLOFLO barges are also used in some situations.

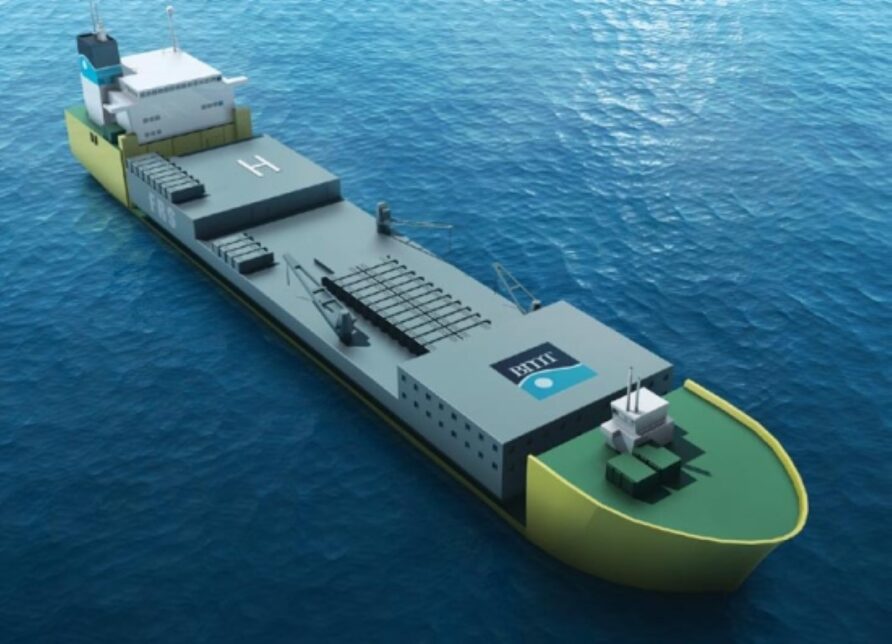

Multi Role Heavy Lift

Some designs are more flexible, able to operate in all three modes.

Rather than a completely flat deck, they have a more conventional hold with movable deck covers and a rear ramp.

Movable deck panels are used to create a deck at one of six levels, and a temporary bulkhead can also be installed to allow the vessel to be submerged without flooding the cargo hold.

The ship’s own cranes can perform all these configuration activities.

Operators

Sample operators include GPO, SAL, AAL, Jumbo Maritime, and RollDock

Example Vessel

As you can see from above, there is a wide variety of ship designs and sizes, some will be less suited to the UK than others.

The Combidock Class is a good starting point, they are not massive, but very flexible.

She can also dock down to accept floating cargo like a barge or, in the example below, a submarine.

The cargo deck is 132m × 18m, enough space for 1,383 TEU.

The later vessels in the Combi Dock series were purchased and converted for use in the offshore industry, a few years ago.

The OIG Giant II, formerly Blue Giant, formerly Combi Dock IV, is just such a conversion.

The work included modifications to the cranes (anti heave and lift extension) and adding a helideck, moon pool, accommodation module (in yellow), additional generators and a Dynamic Positioning system using azipods and thrusters.

The 500 tonnes 13mx18m accommodation module is built across seven decks and includes facilities for 86 personnel, including leisure, sleeping, workspaces and water/waste treatment.

A new build contract at the same ‘offshore’ specification for two was reported to be €200m for the pair.

Ashore Storage and Crewing

The Role 3 module(s) could be stored onshore, at Marchwood, for example.

Crewing could be RFA, or even as part of the strategic RORO service operated by Foreland Shipping

Beyond Role 3

There would be very little point purchasing a heavy lift vessel only to use it on the infrequent occasions when a deployed afloat Role 3 capability is required, might as well have a dedicated vessel.

This is why the multi role-type such as the Combi Dock is attractive, and would allow us to extract maximum value from it.

General Transport

Over 1,300 TEU’s is a lot, but easily carried by the Combi Lift design described above.

They can be lifted on and off using harbour or the ship’s own crane.

Containers could also be off loaded whilst at sea, the heave compensated crane allows much safer operation without pendulation. The containers could be loaded onto Mexeflotes, landing craft or other lighters. With a single crane, this would not be a particularly fast option, though.

At 4m width, there is 528 Lane Metres, with vehicles using a shore based loading ramp or lifted in and out.

This would be across two decks using the standard hatch covers only, each deck being just over 4m high. There would also be space on the hatch covers if it were permissible to carry vehicles exposed to the elements.

The USMC used the MV Combi Dock III for just such a deployment, some years ago.

As with containers, vehicles could be easily lifted onto lighters whilst at sea, in reasonable sea states.

This is not as flexible as a more conventional RORO, worth recognising that.

Crewed and Uncrewed Vessel Transport

Because the vessels are semi-submersible, they can be used to transport small craft and patrol boats, and even submarines (not that we have any of the smaller types that might need a lift)

Smaller craft such as patrol boats or MCM unmanned boats could simply be lifted from the deck into the sea.

Using the two deck approach, the vessel could comfortably transport 110 Pacific 24 RHIB’s, more than we have in service.

Where this gets interesting though is with larger vessels.

A crane lift would be preferred because the lengthy docking down process would not be required.

With one crane, a 350 tonne limit allows a range of fast patrol craft, work boats and hovercraft to be transported to theatre.

We don’t actually have many of these, but with a credible deployment capability, we would be able to exploit the type of patrol craft we don’t have.

More realistic, would be to use it as simple transport for future medium-sized uncrewed vessels.

There is an increasing interest in these size vessels, and they have to move oceanic distances.

Mothership

I would not generally favour using them as a kind of ‘mothership’ because they would be civilian crewed, and neither would it be sensible to use any of the Navy PODS concepts, included here for completeness.

Summary

This is a proposal that both recognises the importance and benefits of a good afloat medical capability at Role 3, and that it is a difficult investment decision.

By looking at imaginative solutions, such as creating it as a ‘super module’, we can generate benefit and wider applicability in a realistic approach.

None of this is cutting edge, the solutions are used every day in industry.

By taking this approach, a module, and a carrier vessel, the carrier vessel can be used for the 90% of time we don’t need a Role 3 afloat.

Maximum value for money!

See you in the comments.

Read more (Affiliate Link)

First I’ve even heard of the RN’s “Flo-Flo’s”! Are they going to be “Open Cover” or “Close Cover” like the USNS Lewis B. “Chesty” Puller class Expeditionary Sea Base Vessels. And what’s the “Base class Design” of the RN Flo-Flo’s patterned after…

How about a guard-ship? Imagine one of those combi-docks with the appropriate ‘big’ module, rocking up as a guardship, with a flotilla of reasonably sized OPVs- maybe not full 90m jobbies, but 3 or 4 40m , well-armed corvettes/ cutters. Or Antarctic patrol ship?

Or, one with an Air Defence Control Centre module, and Air Defence platform (both SAM and AAA), in Falklands Sound in 1982?

The only problem is getting the rn and therefore the MOD, to see the class as a system, rather than a group of ships. I can see the matelots saying something like:

‘Oh what a good idea, we’ll have one as a LPD, one as a MCM mothership, one as a PCRS, one as an aviation support ship, one as a forward repair ship, one as….. da-de-da…..’.

….Rather than buying 6-8 vessels and 12 modules. Their argument will be ‘but we must have the crews trained as complete crews’. TBH, the way you should have them is having the ships operations team and the payload team, as long as both are trained on standardised emergency procedures and protocols (easy if you keep everything standardised) it won’t matter what ship the module is ‘dropped’ onto. It will mean the rn will have to re-learn command flexibility (known as CRM in airlines and the RAF). The absurd situation where the Captain of a carrier could interfere so much with air tasking, as to reduce it’s efficiency, effectiveness and ultimately endanger aircrew, because his experience/ undestanding was outdated, limited or inaccurate must never happen again. The Task Commander, has to be the payload specialist.

A nice read; some proper TD stuff of the old ilk!

“Although many seem to focus on the more glamorous aspects of the ESB, the MCM role seems to be well suited to a future that includes and increasing reliance on off-board stand-off systems.”

– one thing we have never tried, is the high-skirt type of hovercraft for MCM missions

– the USN have, whether they entered service. I can’t remember (they have continued to rely on helicopters alot).

There is (would be!) our self-deploying MCM fleet, in support of an amph. Op. The cost per operating hour is very high, but then again, how often do we storm a beach?

One detail is (to me, a total amateur in these matters) puzzles me: why are the work boats fitted for “push” (rather than “tow”) use?

– one would think that a mexeflote can be kept in use up to one sea state higher, by pushing it (ideally by two boats) against the side while being loaded

Barborossa, you are not paraphrasing the sinking of HMS Glorious, by any chance?

” The absurd situation where the Captain of a carrier could interfere so much with air tasking, as to reduce it’s efficiency, effectiveness and ultimately endanger aircrew, because his experience/ undestanding was outdated, limited or inaccurate must never happen again. The Task Commander, has to be the payload specialist”

vs.

“First to contradict this [officially recorded cover story] was no less a personage than Winston Churchill, who wrote in his account of the war that the fuel explanation was ‘not convincing’. Nonetheless, the official story held for the next 30 years through the publication of the official histories. Yet it would be the Navy’s official historian, Captain Stephen Roskill, who in 1980 finally lifted the lid on the controversy in an explosive article for the Sunday Times. ‘The Cantankerous Captain of HMS Glorious’ drew upon testimony from Captain J.B. Heath, Glorious’ senior aviator, who had missed the sinkings due to having been put ashore before she sailed for the final time. Roskill painted a picture of a desperately unhappy ship run by a captain whose First World War legend disguised incompetence, tyranny and questionable mental stability, who had put Heath ashore when the latter could not comply with impossible orders. So choleric was D’Oyly-Hughes, asserted Roskill, the sole reason his ship was racing home independently, completely unready for combat, was in order to bring forward a court martial against his former [payload commander] officer.”

and

that is just the gist, from: https://www.historytoday.com/philip-weir/hms-glorious-history-controversy

with much more

If we had two or three RN Sea bases, would we have any real need for the LPDs? The only thing not discussed for inclusion on these platforms, and which is the LPD’s ace in the hole, is a modular combined ops room.

@MSR, the Albions are warships, these are meant to stay well behind the horizon.

– except if they are bases for hunting pirates

Strangely, in the collected comments list the MSR comment is under “Mike”? Same or different? not that it matters (exc. to the respective users)

This is an unneeded capability for the Royal Navy and British Forces. I look forward to statements telling me how wrong I am but the simple fact of things is that your forces are too small to make real use of this capability. Even in a scenario where the UK went it alone against a mythical foe, this would still rate as a luxury and not a need.

Consider this. If I recall correctly too MLPs are tasked to support a Marine Expeditionary Force ashore. We’re talking about a US Marine sized formation of approx 45K men. Can anyone here think of a need to put that many troops ashore and sustain them once there?

Additionally the Royal Marines just don’t have the level of mechanization that would require this capability.

Let’s face it. The Royal Marines have beat the US Marines to the “air enabled” moniker. Your two carriers demand that. Your force structure demands an air enabled force.

No MLPs for you. Besides. If you need one just borrow it. The Marines are putting F-35’s aboard the QE…it only seems fair.

@ ACC…

The whole norwegian campaign was an excellent example of why politicians shouldn’t be allowed to interfere with the conduct of operations; in fact WW2 is littered with screwed-up ops, dead servicemen, lost opportunities and sacked senior officers, the common factor in all of them seems to be Churchill, who with his grandiose plans, pure arrogance and ignorance, ranged from sacking very good, competent generals, because they disagreed with him (Ironside, Gort, Alexander et al) through putting cronies in charge of important industries, to the direct detriment of the war effort (putting a newspaper magnet in charge of the ministry of aircraft production) to ordering operations, against theatre commander’s advice, which resulted in manpower and equipment being wasted on ridiculous opium-smokers pipe-dreams, to the detriment of other operations. (Greece, Greek Islands, Gallipoli etc.). Considerering the bloke was the architect of the infamous ‘Ten Year Rule’, and spent his time in parliament vociferously opposing Neville Chamberlain’s plans for rearmament, I would argue he was responsible for extending the war more than any other person….

But no, I was actually referring to the Falklands War and Jerry Pooks account of operating Harrier GR3’s off the Hermes… Examples of the Captains twattery including physically preventing the setting up of a proper intel and planning cell, near the aircrew briefing room, disregarding the two highly-experienced and highly regarded photo intelligence analysts, in one case actually ordering a strike against Port Stanley Airfield, because he’d misidentified a damaged Cessna 172 and Aermacchi MB326 as Super Etendards , withholding intel from the aircrew actually doing the tasking. He had been a Buccaneer pilot, quite a few years before, had no experience of TAC-R, or Phot-R- he even refused Phot-R missions despite 1sqn being highly-regarded within NATO as a recce unit. He changed the profile of tasks, against the council of the CO…. All of this was on top of the whole air-tasking system being ‘creaky’ at best.

…Hence the reason why I said about command flexibility. The captain of a vessel cannot be expected to know everything (even if he has some experience) therefore the Captain should concentrate on the operation and safety of the vessel, leaving the payload commander to ‘run’ the task. RAF Nimrods, Sentry, Sentinel and now AirSeeker operate in exactly the same way, the Aircraft Commander very often being one of the mission specialists. From my admittedly limited experience of the rn this will require a fundamental change in the way things are done. I appreciate the leadership strengths of ‘My Ship, My Responsibility’ but modern war-like operations Involve too many specialisations, for one man to make effective decisions in isolation. Will there be command conflictions? The RAF seem to manage very well, so with properly CRM-trained senior officers I wouldn’t think so.

The worst thing about Glorious was the loss of the 24-odd Hurricanes and Gladiators and aircrew- you have to ask what difference even only 24 trained fighter pilots would have made, not to mention the scarce Hurricanes.

Sol,

Sort of agree, sort of don’t.

If we lose Albion and Bulwark then the notion of borrowing a flo-flo from the offshore oil industry is a pretty sensible move in order to unload the Bays. Basically the MLP brings the LCUs (and possibly LCVPs). The fact that it can also become a floating pierhead is just a bonus.

For what it’s worth, I am a fan of the general MLP concept but not a fan of the way the US executed it. In my opinion, using an Alaska class tanker with its midsection hollowed out 1) Wastes logistical capability due to the open air volume above the steel beach that if enclosed could be put to any number of uses, and 2) Provides more opportunity for Mr. Murphy to raise his head due to the direct exposure to the elements. Why not keep the basic hull structure intact and cut holes for the 3 LCAC spaces, essentially ending up with 3 LCAC sized enclosed welldecks. This would allow what is now open air above the steel beach to be used and it would provided a “sheltered” beach in which to load and unload whatever surface connectors are being used. For connecting up to an LMSR (as pictured in Expeditionary Transfer Dock Image 1) its side ramp may be able to unfold directly on to an upper vehicle deck of the MLP without having to use the ramp in the picture.

As far as a Flo-Flo goes, if the Bays are removed from service I agree with using a basic commercially available Flo-Flo and then designing mission specific inserts for the cargo area. As mentioned in the article the inserts could focus on HADR (with specific “sub” mission focusing on logistics or temporary refugee housing for example), Counter piracy, MCM mother ship. I would advocate the RFA outright buying 2, maybe 3, of the Flo-Flos for “continuous” use but have several inserts available to surge in leased Flo-Flos as needed. For a hypothetical example, after the hurricanes of this past summer Britain could have surged 6 Flo-Flos to the Caribbean for HADR ops with 2 carrying refugee inserts, 2 logistical inserts, 1 medical insert, and one Salvage Repair and Fire Fighting insert.

One of the more intractable problems with FLO-FLO is their availability. DTMA can (and do) contract these things off the spot market, but for an arm and a leg. That’s because they’re usually booked up for months – if not years -in advance. This can fluctuate depending on the fortunes of the world economy (and the yacht charter season) but in general you don’t get contracts that allow for MoD access within required readiness / reaction periods.

Been looked at many times over the years.

@Barborossa, for your 2nd latest: My favourite Churchill quote

“History will be kind to me. I know it. I am writing it”

And for the very latest: Yes, the incredible feat of landing 7 Hurricanes onto the carrier deck, intact, went all to waste

RE: “an Alaska class tanker with its midsection hollowed out 1) Wastes logistical capability due to the open air volume above the steel beach that if enclosed could be put to any number of uses”

– but gives a 30% chance that a ship-killer missile flies “straight through”?

ACC,

As far as I know, MLPs are not meant to be used in a denied/contested environment as they are not warships. I would argue that, while certainly possible, the probability of being successfully attacked by an ASM is not high enough to justify the loss of cargo capacity. Since the MLP is not a warship, I also assume that it will not operate unescorted if there is a threat of an ASM attack against them regardless of the environment they are operating in. If needed as a last resort prior to a “combat” deployment self contained CWIS systems like Millenium/Skyshield could literally be bolted to the upper decks to provide that last ditch defense if one is so worried about an ASM leaker. I know I don’t have all the information and so I recognize that maybe the MLP, as currently configured, is the optimal solution for what it’s meant to do, I just can’t help but think of the logistics capability that is “wasted” due to the missing midsection.

NAB,

Yes I understand that Flo-Flo are a low availability item due to their high demand which is why I recommended the RFA buying 2-3 of their own for normal/continuous operations and training. The leased (cough commandeered) route would be used in the exception/emergency case, like HADR ops, where it could be win-win for all parties in that the RFA gets what it needs and the companies involved get some good “we care about people” PR out of it in addition to the monetary compensation from the emergency lease.

@Barborossa

I’m not so sure Chamberlain was all that hot about rearmament, especially since he was the one who was going ‘Peace in our time’. Him proclaiming peace while clamoring for rearmament seems a bit dodgy to me.

While I’m at times dismayed by Sol’s hyperbole and sometimes slanted views, in this case I feel he’s spot on with his analysis, the current situation of the UK and the state of the armed forces as it is now does not warrant this degree of expeditionary expenditure. As such, any speculations along this line comes more under the ambit of ‘window shopping’ rather than ‘military planning’.

Never really thought about this before but the logic seems sound.

Would these be a suitable replacement for the Point class contract – giving us more flexibility and potentially the ability to make some money by using it commercially, as there does seem to be a market for them.

1. I like the idea of the large hospital solution – although have to say I think we should have a fleet of hospital/HA ships as part of our foreign aid budget.

2. The ability to act as a mothership with a well dock for hunt/sandowns seems a very good idea as well or to even launch a battalion of RM in CB90’s or LCU’s (or combination) would be great.

3. The ability to have a forward repair module (or 3) that we can forward base as necessary also seems sound.

And we always need somehing to move containers dont we.

Given the price of these and their potential usefulness I think these should be brought in when we replace the Point class, which will give us time to develop how best to use them.

I guess we underutilise our points and if we could have something that gives us more flexibility and brings back capabilities we have recently lost then all good.

Would not the HMS Glorious problem be avoided by having the ship commanded by a permenant RFA Captain, but the Task Commander being a suitably senior commissioned officer of whichever service’s module was on board. The respective roles and responsibilities would then be clear. Presumably this happens at the moment when a Bay Class is deployed with a warlike contingent on board.

Pacman – I would have thought the Bay Class would be more at risk of being replaced by these ships.

I must admit to being rather taken with the Flensburger 2200 ROROs for this sort of role. SeaTruck/Stena operate a quartet of them from the Isle of Mann and they very much fit the bill of a modern economical Argus.

https://www.niferry.co.uk/look-inside-stena-precision-sept-2017/

Super sized modules.

Marvelous!

Do we need to own the Heavy Lift Vessel(s), that would/can carry the various Large Modules? If so how would the HLVs “earn their keep” when not needed to carry/operate with one of the various Large Modules?

Or, could/would we just own the various Large Modules, and when required deploy/move them aboard Heavy Lift Vessels “taken-up-from-trade

( STUFT) ?!

Great article Matey ! A fantastic analysis, of course…..

So where to begin. I think as you tried to point out, we need to start with what capability is exactly that we think we want ? Is it an actual single role hospital ship, a multi-role civilian disaster response ship, or a multi-role Naval auxiliary to take on the Role 3 PCRS tasking (among other things) ?

All are capable of providing one or elements of the UK’s “disaster response” and “humanitarian aid” capability set.

1. Single role, civilian (DfID) hospital ship – you state this bothers you as what does it do when it’s not responding to a disaster ? Well it uses up more of DfID’s aid budget and provides significant “soft power” by moving from African port to African port, hosting MoD,, NHS, MSF or medics from any other organisation, doing surgery that local health systems can’t, down to industrial scale cataract fixes etc. Yes it may be badly positioned when a disaster strikes some place else, but probably easy to get underway quickly than it is to crane the giant modules onto the mother ship.

2. Civvy multi-purpose HADR capability. Something less hospital-y but with some lane meters for useful rescue stuff like bulldozers, JCB’s , cranes, even fire trucks and ambulances. Engineering kit to help open or create an airfield, containers full of relief supplies, and the ability to generate clean water and power to pipe ashore. Depending on the size, this could indeed by your modular concept. Keeps the budget down through all the key points you mentioned in the article. Military roles you mentioned, such as moving a repair and support barge to theatre etc.

3. Naval Auxiliary. A full on RFA as a like for like replacement for Argus. This could be a merchant conversion as you discuss, It could be a new build based on the Bay class or one of the Damen Enforcer derivatives (of which the Bay class is one): https://products.damen.com/en/ranges/landing-platform-dock – or it could be a simplified version of HNLMS Karel Doorman, in other words a variant of the Damen Joint Support Ship design – maybe with a bigger hospital and without the RAS capabilities. https://products.damen.com/en/ranges/joint-support-ship/joint-support-ship

Such a vessel might be “overkill” for once a year hurricane relief in the Caribbean, but what is stopping us from using it elsewhere ?

So the question is, how much do we need the military capabilities afforded by RFA Argus ? If an RN / Marines / Army amphib “squadron” consists of a single unit of Albion class, Bay Class and Strategic lift Ro-Ro, then even if we are indulging un-opposed landings in your port opening and force protection scenario as discussed in previous articles, the extra flight deck and aviation capabilities of an Argus replacement based on a Bay or the Karel Doorman , as well as the PCRS capabilities would appear to be extremely useful in the absence of an LPH. Similarly such a multi-role vessel provides for other elements of HADR, not just the medical facilities, but the C3, vehicles carrying, cargo carrying capabilities etc.

So what end of the spectrum do we think we need the most, a vessel with military utility to replace the one we have, or a white painted civvy manned flag flying good will machine oozing with soft-power capabilities ? Once we have figured that out, we can figure out how to deliver the capability because one way or another they could be both be based on your heavy lift ship plus modules concept.

Great to have the good old TD std – rather than just back and forth (I won’t mention “the” Brexit! – as a corollary)

Anyway, here the ‘shorthand’ for it would have been University-level Hospital, with an A&E specialisation?

“The Role 3 medical facilities can flex but in the largest configuration is designated as 4/4/10/20/70 which means 4 resuscitation bays, 4 operating tables, 10 intensive care beds, 20 high-dependency beds and 70 general beds (in two wards). Other facilities include a dental surgery, imaging (Ultrasound, 64 slice CT and X-Ray), pathology, pharmacy and physiotherapy. She has an oxygen concentrator and various laboratories.”

– how doesthe above compare with what was set up in Camp Bastion, btw?

– that was for one brigade (3000 frontline, with another 6000 in a supporting effort)

There are only two options in my mind: 1) Bay Conversion, or 2) Flo-Flo Module.

The reason is that however excellent Argus is she is difficult to justify the rest of the time. Aviation Training Ship was one justification – less applicable now. The other was a poor-mans LPH – which she wasn’t much good at. I can’t see a dedicated facility being anything other than HMC Ocean painted white. The trouble with this is we know full well how important an LCU in the back would be for disaster relief and/or moving medical equipment and people to/from shore.

The nice thing about the Flo-Flo with Hospital Module is that the ship can be leased to civillian operations and also used for amphibious support. If it can also provide Forward Repair and replace the capability lost with Dilligence then even better.

For the time being however simply taking one of the Bay Class and fitting it out with the necessary facilities makes the most sense. There are numerous reasons for this. One being that given we’ve only really got two Commandos we barely need the third LSD. Another being a difficulty in crewing the ships and using it as a dedicated humanitarian ship will change the recruitment profile. The last is that it has a well deck and can take an LCU (again, painted white). I’d also attempt to make the hospital fitout modular. If only to exercise the brains of the designers and get used to this kind of thing for future projects. The “modules” do not have to be easy to fit, do not have to be containers, do not have to be wheeled. They also don’t really have to ever be removed. The ability to do it should push come to shove is all that is needed.

PS: I’d have kept Largs and done this with two of the Bays a long time ago.

PPS: Alternatively, sell another Bay to Australia (if they need two) and use the proceeds to buy the Flo-Flo option.

I remember that the U.S. didn’t deploy either of its two hospital ships to the Sierra Leone Ebola crisis. They did instead create a ridiculously inefficient (100+ troops per medical bed) field hospital.

There was a suspicion that the ships might have been unsuitable for such outbreaks because of insufficient quarantining capabilities.

A new-built hospiral ship yould have proper disinfection (including the climate control piping and filters) to deal with all kinds of infectious diseases outbreaks.

The ship itself would cost € 100 million or less. The expensive part would be the medical modules. I do thus doubt that a containerised (40 ft ISO) solution would save much cost. It might keep the whole hospital deployable to inland locations, though.

I should have added:

Plenty drinking water generation for disaster relief is a must (for a couple ten thousand people), including storage of huge quantities of empty plastic water bladders with easily used screw-on plastic cap and pallets good for transport on pickups.

Also, huge pharmacy stocks.

For my ha’pennysworth, the functionality of a Flo-Flo ship is the dock space it offers, at least in the commercial world, whether this is in use as a dock, or for containers, or for modules or whatever. Whether in use as a hospital ship or in other (military) roles, a simple adaptation of an existing commercial design would be missing a lot, not least a lot of accommodation. If the FloFlo space is used for housing that restricts the utility of the vessel as either a hospital ship or for other transport/amphibious roles. That said there are many attractions in having a great big dock available; the ability (in a military context) of carrying large numbers of landing craft, or other kit; high capability hospital modules plus the helodecks and (ideally) at least small dock to get best use of the hospital. All as per this post and one or two previous TD posts…

We ought also to consider the need to replace Bulwark and Albion in the future. Perhaps even we could think about preserving what’s left of the UK shipbuilding industry…

It is possible to imagine a three-ship buy phased over a number of years of vessels of the same design but capable of fulfilling different roles due to their inherent flexibility. To be a Geneva-convention hospital ship we would have to ensure that any weapons fitted were easily removable (e.g. containerised) but apart from that the legal differences are mostly paint. If we consider that DFID pays for purchase and running costs of one ship to be permanently fitted with hospital modules at least in peacetime and MoD purchases two more to replace thz LPDs, and we order all from the same shipyard consortium in UK with the build spread out over a decade …. it should be possible to get a good deal, especially if the military requirements are kept in bounds. Albion and Bulwark when purchased were not so expensive…

To be an LPD as well as a hospital ship a FloFlo would need lots of accommodation for either soldiers or medical staff. It would need space to store munitions (or pharmaceuticals) and space for water purification plant (?containerised in a hold should be possible) or stores and vehicles. And it would need a bloody great dock. If we contemplate a length of 130M and width about 16M that allows potentially 8 LCUs (and I know UK only currently has 10); if we have a dock depth of 13M plus that allows potentially LCUs below in a floodable part and a tweendeck above carrying further equipment; if the tweendeck is moveable while loaded then it could be used for still more amphibious craft of smaller dimensions than an LCU. That would be a very efficient use of ship volume in an amphibious role, while being completely compatible with the need to get big hospital (or other) modules in and out for other functions. The US LSD41 Whidbey Island class is currently in service with this length of dock although not this useable depth nor with a tweendeck.

Assuming the dock is roofed over with removeable [to allow module installation] decking which can support heavylift helicopters it also gives a 130M long flight deck about the size of RFA Argus’ and big enough for three Chinooks to be spotted. We could then envisage the front end of a Bulwark/Albion type vessel for the crew and on board personnel space and storage space flexible enough to meet the needs of the various roles, up to and including the C3 installations for an amphibious landing. This would be a big ship, at least as big as Argus and probably significantly bigger, but as it would mostly contain empty space in the dock it need not be excruciatingly expensive. For the hospital role about 65-75% of the dock would be used for modules leaving a useful space remaining for a helodeck above and landing craft below. As far as manning goes I would propose that all three vessels should be RFA manned permanently. I know the LPDs are not but the Bay class which perform similar roles in similar areas of conflict are, as are all the RN’s Fleet Support Ships; all these carry weapons and have to go in harm’s way. For a civilian role as a hospital ship for DFID the RFA as civilians would be potentially an advantage. Generally speaking, one ship would be hospital roled permanently, but when it is refitting or otherwise unavailable one of the others could be reroled fairly simply… and of course vice versa if the need arose. Of course it would be best to have a fourth ship to cover refits etc. but that is probably too optimistic. For the manning of the hospital element the ideal way to do this would be with military medical service reservists who would gain valuable medical and on-board experience in peacetime for DFID which would then stand them in good stead on callup for ops as soldiers/sailors etc.

And finally all the above only extends somewhat the ideas already put forward in TD in a number of posts which I think are extremely sound.

How about a jack up hospital barge? When the FLO/FLO moves it in-theater, it can be floated off, moved near shore, and jacked up to provide stability. The FLO/FLO can then be freed for other tasks. It could include a an extendable ramp to allow vehicles access.

Just been doing some sizing and if TD’s 120m x 60m Role 3 is anything to go by then that should fit perfectly into Bay’s 120m x 20m x 3 story vehicle deck.

“We can’t help them and kill them at the same time, it just ain’t humanly possible”

General Glenn McMahon – War Machine

I’m not a fan of the foreign aid situation, you could halve it to fix defence and still be near the top of the list, with an enviable hard and soft power mix. But, this all looks a bit naughty, however it’s presented some will interpret it as a navy raid on the foreign aid budget and you could conceive of a situation in which a hospital ship that had been floating off some distant shore could be going back six months later with the marines and prove them right.

That said, a great article as always and weighty enough to deliver aid by itself, the FLOFLO idea is inspired, from a psychological perspective I like the message that physically dropping a hospital on their doorstep would send to people in their time of need, well there’s that and that for the module cost the navy could leverage its own hospital, repair ship and an expeditionary transfer dock from the deal. The SBS could also finally steal an entire ship and its crew, which I think they’ve been wanting to do for years.

I think you’d sidestep the moral grey area by putting the modules in different budgets and having the RFA simply provide delivery, to that end the foreign aid budget could pay into the RFA budget for developing the capability and for guaranteed availability in the same manner that the MOD pays on its PFI for the Point Class.

Nemo

Great article TD. I am very in favour of a flexible ship conducting joint-funded missions and hope we can resource it in coming years.

What about a British version of the Dutch Karel Doorman Joint Support Ship? Looks to me to be an ideal Argus replacement: capable of being the offshore sustainment platform in war and HADR operations, aviation training role, C4I hub and even undertake RAS tasks.

https://products.damen.com/-/media/Products/Images/Clusters-groups/Naval/Joint-Support-Ship/Deliveries/Product_Sheet_Damen_JSS_Karel_Doorman.pdf

https://m.youtube.com/watch?v=Xn5v7tEBYn4

http://brickmuppet.mee.nu/maritimematters/more_ideas_for_naval_numbers_on_a_budget

I think the idea of a giant module is neat, however the sheer size requires very large lifting gear available where ever it is removed/ stored. FLOFLO is another neat idea, however I would suggest a 4th alternative: a Tug/ Barge combination.

These are designed to work as a unit at seas yet are easily separated. Sometimes they are used as rule beaters depending on local maritime law; other times they are used when loading and unloading takes a long time – in that use case, one tug can operate multiple barges.

The single “tug”, which in this case would be rather large, could do some transport/ response/ patrol duties on its own or it could mate with multiple barge options depending on the mission – dedicated hospital, disaster response, equipment transport, etc.

In the case of a national asset, I could see having a number of barge options, some of them prepositioned and used as floating facilities, and then 2 or 3 tug units to move the barges as needed.

A hospital barge could be used pierside in a big city during normal times, then moved as needed elsewhere; an equipment barge could be a warehouse for a military or civilian unit and then be moved as needed also.

While these roles could be covered by a large module or a FLOFLO barge, those both require more significant assets to enable movement than a tug (very large shore cranes, or a heavy lift ship). In special circumstances, the barge part of a tug/ barge combo could be towed by any available vessel, such as commercial tugs (even a destroyer or tanker depending on relative sizes). However, the history of large traditional oceangoing barges isn’t the best, so as firmly mated tug/barge combination is better in terms of speed and handling bad weather.

Just a few thoughts…

Fascinating , thank you for the work that goes into your posts, a lot of them are very technical .

I am mindful that we are moving into an age of austerity but think the idea is a good one , it can easily be funded both from defence and overseas aid budgets .

Do we buy second hand and adapt it , buy a design and build under license or do we design and build from scratch . My vote would be to buy a design and build under license

I wonder how the change in scale of amphibious operations away from brigade operations to smaller scale more special forces type operations changes the need in scale for the size of hospital that supports it.

The French example of using its mistral ships for the role 3 hospital is one to consider. But perhaps if we are intending to include its provision in more than one location at a time something like the Norwegian maud maybe more appropriate given the new scale we are operating at.

Would it not be the most efficient solution to have the hospital consist of several "mega-modules", each a barge of, say, 200 tonnes and providing a single ward (I have no idea how big each would need to be to provide any particular level of capability)? That way, the combination of modules carried and deployed by the ship can be tailored to what situation is likely to be faced. For example, responding to an epidemic in Africa is going to need a lot more ICU beds and a lot less operating theatres than a war zone.

Additionally, having smaller self contained hospital capability could allow different deployment methods. The reason I described each one as a barge was because it might be possible to float one or two inside the well dock of an MRSS, if indeed MRSS is going to have a well dock. That way you have a high/low option of integrating within the amphibious capability or a standalone giant hospital ship.

Going beyond pure hospitals, I really like the idea of replacing the Point class with the Combi Dock sort of multirole heavy lift ship. Recently we have seen Points carrying P2000 patrol vessels that had broken down, showing that they at least have a basic vessel carrying capability.

In the lifetimes of whatever replaces them, there is supposed to be a massive growth in the number of medium sized unmanned vessels. For example, the RN might follow the Dutch down the "loyal wingman" missile USV route and there are already XLUUVs in build with more and bigger designs coming down the road. Being able to move these globally will be a very useful asset.

I also think that you understated the capacity of these ships for RORO type lifting. They have the same rear ramp style as the Points and I imagine you could install a middle deck shelf for lighter vehicles as well as the exposed upper and main cargo deck spaces.

Done properly, this is a massive opportunity to expand the RN's heavy lift capacity in a multitude of ways, it just needs to get done. I don't care who builds them, either.

Mark1, I think that is a very good point, the reduced size of amphibious ops, but Role 3 is also for those onboard ships?

Sailorboy, great points

TD, do you have any stats on the floor to ceiling height of an LCU 10?

Those have a 240t max displacement and are a useful base footprint for fitting inside our other landing ships.

I want to know if you could fit two floors inside one or if a theoretical hospital barge unit would only be able to have one plus pipework. Would ideally also need ISO fittings to allow stacking inside the combi dock.

As a sort of static "Mega POD" we could then develop several different types of standard liftable barges for repair, floating ammo storage etc.

I'll ask on Twitter

I've had a look at the Shipbucket diagram for the LCU mk9 and that suggests a height of 24 feet minus antennae, no idea if they retained the same height for the mk10.

Looking logically at the layout, there looks to be a complete deck underneath the bridge plus a very thick floor, so if the "ground floor" were sunk into the hull slightly two floors would fit easily.

I saw your tweet, thanks!

Answer for you?

https://twitter.com/RKSL_Rock/status/1843367174968357077

Thanks

Have now got carried away and am designing a whole set of barges based off the LCU footprint, including:

Hospital ward

MCM control/maintenance base

ammo/fuel dump

command headquarters

barracks

Vehicle repair platform

The idea is that they get shipped to where they are needed in a Bay or Albion and then left anchored or moored in any random port, where they provide an instant logistical capability you wouldn't get otherwise.

You should do a guest post, would be happy to help

Thanks for the offer.

I'm currently in the "hammering out basic arrangements on PowerPoint slides" stage, but I'll try to remember to get back to you once I've worked something out.

One thing: for ammo storage, what's the typical arrangement of pallets and/or huts to improve protection? The idea is it sits in the harbour away from everything else and you fetch pallets using a LCVP and crane on the barge.

Generally, you would try and disperse them however you could