Trailers are an uncomplicated way to provide additional payloads for any of the vehicles in the previous sections, crewed or uncrewed, wheeled or tracked.

This post will look at conventional trailers first, and then examine options for a slightly different approach that sees tractor/trailer combinations like we do with conventional logistics, i.e. a small prime mover with little or no carrying capacity, but with the ability to tow a larger and heavier trailer.

I will also look at extending this concept to the carriage of personnel!

Trailer Geometry

Traditional articulated vehicles aren’t generally considered for internal helicopter carriage for several reasons, one of them being break-over angles.

The longer the trailer and the closer to the internal height of the aircraft, the more potential for grounding on the ramp pivot point during loading and unloading, especially for Merlin which has a steep ramp angle compared to Chinook.

Geometry becomes critical.

There are design approaches that can mitigate this, but we are in the realms of significant modification and bespoke designs. Trailers can be unhitched and loaded and unloaded manually, but for larger and heavier trailers, this can be unsafe or even impractical.

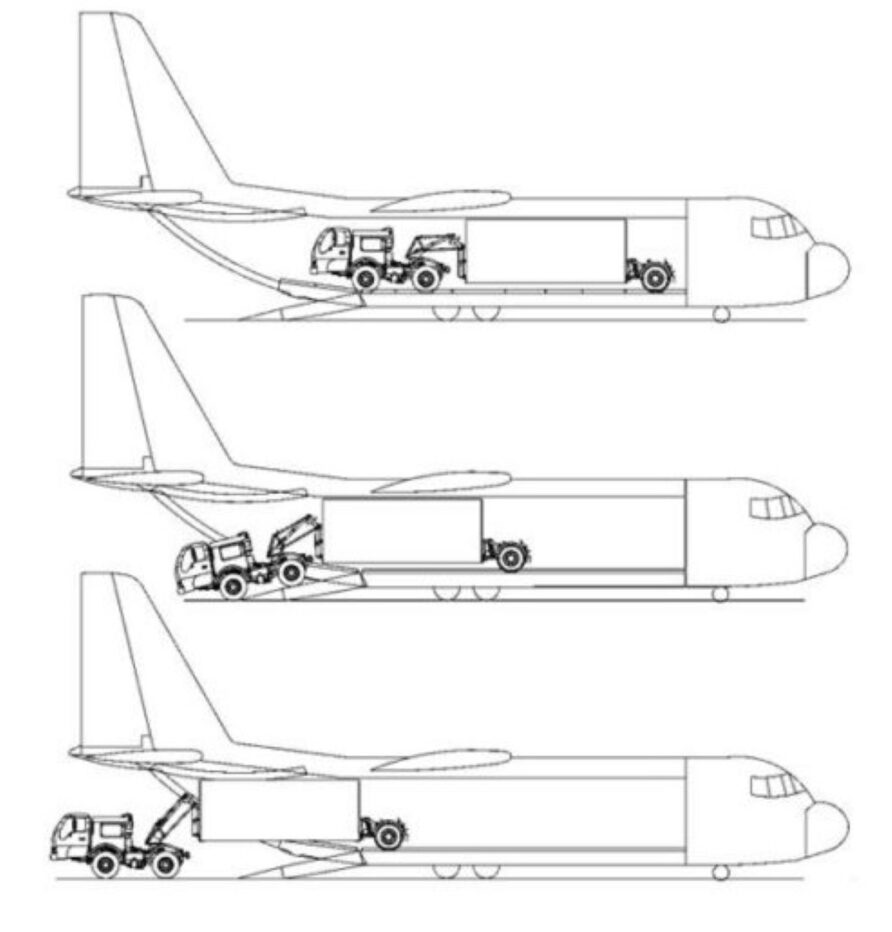

To illustrate this, a vehicle that solves the problem, albeit on a larger scale.

The Italian Aris Airlift Global Carrier (AGC) approaches the break-over angle problem by using a gooseneck trailer with a hydraulically actuated coupling.

As can be seen from the diagram below, the payload is kept level by elevating the coupling as the tractor unit exits the aircraft. When the tractor unit is off the ramp, but the trailer wheels are not yet on the ramp, the coupling is lowered and the vehicle as a whole clears the aircraft.

Loading is the same but in reverse.

This is very clever engineering that also keeps the load level during loading and unloading, allows the load to maximise available space in the aircraft and negates the need for any loading equipment.

A container dolly wheel and flat load bed are also available.

Would we want to repeat this on a smaller scale for helicopter transportable trailers, perhaps not, but it shows that the issue can be addressed.

Wheeled Trailers

The in-service Logic SMT 171/172 trailers are a well-developed design.

They have many features specifically for military use such as fold-down brackets for short gap crossing ramps, fold-up hitch and mountings for a single stretcher.

Longer and higher capacity trailers could be used, single or twin axle, aluminium or MDPE body, tipping or fixed, wheels inboard or out.

A similar trailer design can be used as a dedicated stretcher carrier.

Although going somewhat against the principle of everything having multiple uses, the ATR Trailer from All Terrain Res-Q in the US does look effective.

Flatbed trailers can be used to carry various small engineering plant, there are numerous designs commonly available off the shelf.

Tipping and hook lift (DROPS style) trailers might also be useful and could be used for recovering unserviceable quads and quickly dropping off stores, without manual handling.

The MRZR trailer is capable and compatible with quad ATVs

Larger trailers can also be pulled, and other third-party solutions are worth looking at.

Argo makes an amphibious trailer in two or four-axle versions, the latter having a capacity of 635 kg and the former, 275 kg.

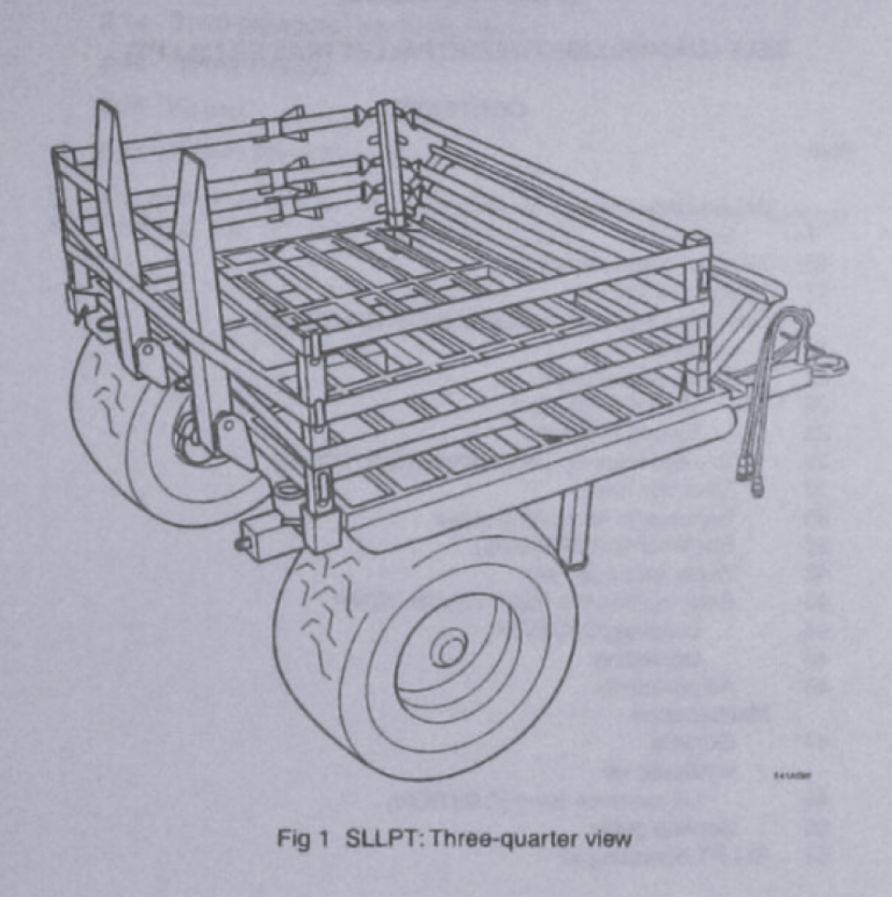

The Supacat ATMP had an ingenious self-loading pallet trailer, mostly used for artillery ammunition.

Although there are variations, the basic trailer had a hydraulic tipping mechanism and pallet forks. The driver would tilt the trailer into the down position, reverse onto the pallet, tilt the trailer back up, and drive away.

The maximum payload for the ‘flipit’ trailer was 1,400kg, and it could also be converted to carry three stretchers. Demountable corner posts could also be used to form sides for loose loads, with ratchet straps used to secure the load, and a water carriage pack turned the trailer into a water bowser.

Pallet bins could be used for loose items.

This brings me to another solution from the agricultural industry, specifically the part that concerns itself with grapes and apples; orchard bins and trailers

Orchard bin trailers use tilting load beds, chain drives, and either PTO-driven hydraulic pumps or a hydraulic take-off from the tractor unit to energise chain drives and tilting mechanisms to quickly load and unload the bins.

Orchard bins are pallet boxes by another name.

A simple bin trailer is shown below, the trailer is reversed onto the pallet, secured and then the vehicle drives away.

Larger pallet boxes such as the 2.16m × 1.0m, 1,120-litre Dolav ACE SL2160 are shown below.

Pallet boxes are available in various sizes, and with lids, drain plugs, dividers and in various colours (thankfully). Disposable liners are used to transport liquids such as fruit syrups and chemicals, but also fuel and water. The US Army used a similar a few years ago for air despatch, called the Lifeliner CUBE.

There are larger and more sophisticated orchard bin trailers.

One alternative is to replace the rollers with forklift tines. Operation is comparable to the ATMP trailer, it is reversed onto a pallet and then the tines are hydraulically raised for transport.

Some have a higher lift travel so they can also be used for stacking unstacking and carrying more than one level of pallet boxes.

Another choice is to revert to tilt beds and rollers but use a chain drive to load and unload the pallet boxes. The chain drives are generally hydraulically driven, with the hydraulic feed either PTO driven or direct from the tractor unit if available.

Four bin trailers are usually approximately 7m long, too long for a Merlin and leaving only a couple of meters for a tractor unit in a Chinook, but by using a double stack of reduced height pallet containers or simply a bespoke plastic box, good packing density can be achieved.

This type of pallet trailer is arguably a little long for helicopter carriage, but the thing about trailers is they are simple, cheap, and easily customised by their manufacturers.

It would be easy to specify a three-bin trailer using the same design, with the bins being 1.2m × 1.2m and any height needed, I don’t expect it would break the bank.

Back to defence

The LV-TEH Combat Support Platform from Latvia looks interesting.

Originally intended as a 6×6 ATV towed mobility platform for weapons like the 12.7 mm HMG and 40 mm GMG, they have evolved the concept to include several ‘modules’

All interesting.

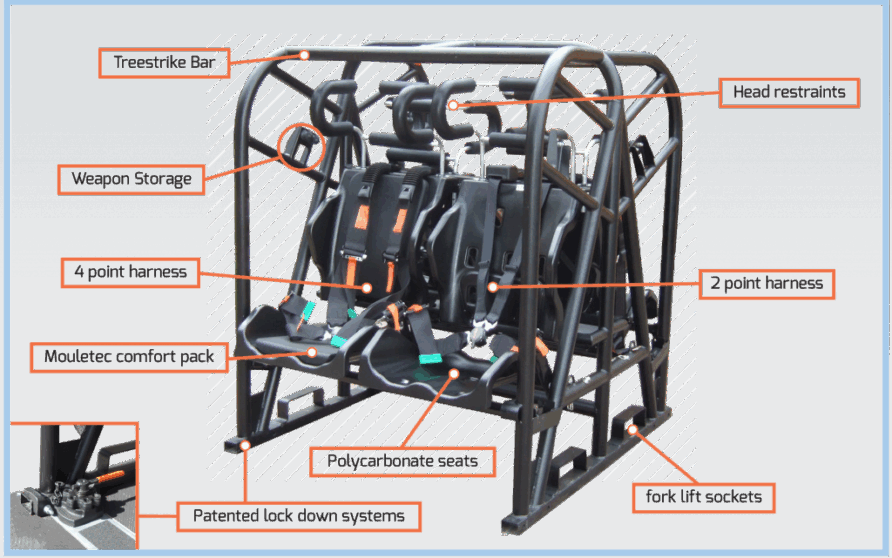

Personnel Carrying Trailers

In addition to those above is a personnel carrier version, equipped with four seats.

A single Merlin could carry one of these trailers and a Can-Am 6×6 Outlander, 6 seats in total and a flat load bed with over 300 kg of payload.

Although I am not going to go as far as suggesting a golf trolley tag-along trailer, there are manufacturers of ATVs and tractor-trailers designed for carrying people at low speeds, Access Trailers in the UK, for example.

The smaller models are light and have bench seats for between 4 and 6 people. A detachable ROPS could be fitted.

Larger models are used for rescuing people from flooded areas, shooting sports, countryside tours and estate management.

Rated at 3.5 tonnes, they are suitable for UTV towing and less than 1.6m in width, with seating up to 14 persons, 3m body length.

Larger models for larger vehicles…

There are numerous other combinations.

Both VSS and Protek in the UK make ROPS modules that could be fitted to a trailer to improve safety.

These would be for simple A to B moves at relatively low speeds and on relatively good surfaces.

Driven Axle Trailers

All the trailers above have undriven axles, driven axle models can improve traction and mobility, especially in poor ground conditions.

Axles can be driven directly from a Power Take Off (if the driving vehicle has a PTO), via an onboard hydraulic pump, using the towing vehicle’s hydraulic supply (if it has hydraulics), and more recently, electrical drive.

An example PTO-driven trailer is shown below.

A great article at this LINK describes how a PTO-driven trailer was used on the Land Rover Forward Control vehicles.

The video below shows a PTO forestry trailer from Proengil in Poland.

With an unloaded weight of approximately 1,500 kg (without crane), it has a payload of 8 tonnes. The crane would need to be removed (it wouldn’t fit) and the log stakes replaced with a standard load bed. 2.5 tonnes for the tractor, 1.5 tonnes for the trailer, leaving about 6 tonnes for payloads if using a Chinook, about 700 81 mm mortar bombs in their packaging.

HM Trailers in the UK make a range of similar trailers, as do Pfanzelt. Black Bruin in Finland and BPW in Germany the driving vehicle hydraulic system which provides the operator with much more control for the Agro Drive, at a larger scale.

As part of a broader systems approach, this could be a useful feature (more on engineering plant later)

Tracked and Ski Trailers

To complement the tracked vehicles in the earlier part of this series, and for use in deep snow, tracked and ski trailers can be used.

For skis, the simplest of options is to just attach them to the wheels of the trailer, it is as simple as that, as this video from Iron Baltic shows.

On snow, specialist ski trailers can significantly improve load carriage.

Matched to their Sherpa designs, Alpina manufactures a trailer system called the Transalp that can be figured with seating or a flat load bed.

The higher power models can easily tandem tow multiple units.

Tracked trailers can be driven or undriven, both are generally used for larger trailers but are still applicable.

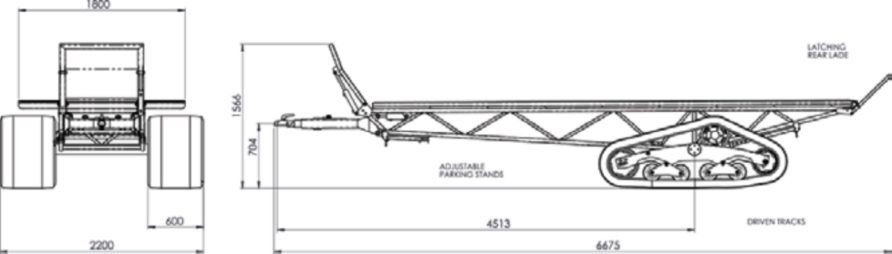

The Sno Cat Two Track Trailer is available in two models. At just under 2m wide and 4.3m long, weighing 590 kg, the Two Track Light has a payload of 1,100 kg.

The PTO-driven tracked from Loglogic is shown in the image below, with a weight of 1.3 tonnes, it can carry 2.5 tonnes.

With 600 mm tracks, it is too wide, but replace them with 400 mm tracks (as per the manufacturer’s options list) and 100 mm is removed from each side, bringing it within limits.

It is too long to fit inside a Merlin but with a towing vehicle of less than 3m long, it would fit in a Chinook.

Two Wheeled Tractors

Bear with me on this.

The walking, or two-wheel tractor, is not a common sight in the UK, but they are quite common elsewhere.

This is what 5.6 tonnes of rice looks like, an incredible payload for such a small unit, although I doubt it will be winning any speed trials any time soon, and I expect a kerb would give it trouble.

This is the point of two-wheel tractors, they are not fast, but they are incredibly cheap and built for shifting weights.

They have a Power Take-off for implements and reversible handlebars to enable pushing or pulling., and the more sophisticated models also include options for remote control and battery power.

In our use case, every cubic metre counts and if we can use that engine and PTO for other things, we are maximising volumetric efficiency, however silly one might feel riding one.

They can be bought from several UK, US and European manufacturers, one does not need to go too far to find them.

Example manufacturers include Casarzo, Koeppl, Lampacrescia, Bertolina, BCS, Grillo, Ginko, Rapid Tractors and Barbieri

Maximum speed tends to be no more than 10-15kph, some are available with zero-turn electronic steering and in power ranges between 8hp and 40hp, diesel or petrol.

Weights typically range from 150 kg to 250 kg.

Below is an example from BCS, their largest model, the 570 mm wide 780 HY Stargate, as can be seen, the handlebars have a wide degree of articulation.

Smaller models are available, but I wanted to use this as an example of how a quad bike alternative, whilst much slower, can provide a sensible option when space is constrained.

Now obviously, mobility is not brilliant, and speed certainly won’t be, but this is the nature of trading payload for speed.

Unlike quad bike ATV trailers, two-wheel tractors require a seat, but again, there is a wide range of manufacturers that can provide an equally wide range of trailer options, the one below costs six hundred quid.

Because of their configuration when attached to a trailer, carriage density is not good.

Unlike quad bike ATVs, two-wheel tractors generally have a Power Take Off (PTO) which means a powered trailer (the one below is from Errepi) can be used to create a 4×4 system.

Two-wheel tractors are hardly a statement of war, they are slow and can be noisy, but if the low speed and comedic visuals can be accepted, they are a reasonable way to shift a fair amount of kit quicker than on foot.

Compact Wheeled Tractors

ATV qualities are well known, but if they are being used as a prime mover (tractor unit) for a trailer, then it is also worth looking at actual tractors.

If expanded trailer usage were acceptable, especially for personnel carriage, the tractor unit could be something apart from an ATV. These ‘prime movers’ could be wheeled or tracked, but optimised for towing capacity and allowing the use of larger trailers.

Antonio Cararro Protector 100

Orchard and vineyard tractors are a specialist vehicle type, but their narrow widths and low heights lend themselves well to the internal carriage requirement.

The 40kph Antonio Cararro Protector 100 orchard tractor is a good example of this type.

With a fully enclosed (and pressurised) cab, it is 1.74m high and even with the widest high floatation tyres, only 1.5m wide, no problems for either Merlin or Chinook. It can also use a folding roll bar which reduces the height to 1.2m when stowed, but it is easily low enough with a fully weather-protected cab.

Because it is a tractor, it has no payload or passenger capacity itself, but it is highly mobile, weighs less than 2.5 tonnes and can operate at speeds up to 40kph.

It can tow a large and heavy trailer, including those with PTO or hydraulically driven axles.

They tend to be about 3.5m long, leaving space in a Merlin for a relatively short trailer, but in a Chinook, much longer.

Although pallets are less likely for this application.

More conventional compact small tractors are made by Pazagilla, John Deere, Farmtrac, Branson Tractors, Claas, Landini, LS Tractors, Zetor, Bad Boy, Star Tractors, Shibaura, New Holland, Tym, Kioti, Kubota, Captain, Massey Ferguson, Solis, Iseki, and BCS

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless. I have removed those annoying adverts, but hosting fees, software subscriptions and other services add up.

To help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

You can click on an affiliate link, Buy Me a Coffee at https://ko-fi.com/thinkdefence, download an e-book at https://payhip.com/thinkdefence or even get some TD merch at https://www.redbubble.com/people/source360/

Youtubers, if you are going to lift content from here, the decent thing to do would credit me

Tracked Tractors

From the small to the large, tracked tractors deliver extra traction in poor terrain.

Micro Tractors

There is a group of tracked micro tractors and crawler units that might not have much utility for longer moves but might be useful for manipulating trailers whilst loading and unloading helicopters, moving small loads locally, or crossover tasks with some engineering plant described later in this series.

A small crawler track unit like this from Agrrizeta in Italy.

Yes, this is a mower, but it has a PTO that can be used with a sit-on trailer.

More conventional micro-tracked tractors such as this 1.8m long example from Mira in Italy would provide a little more comfort for the operator.

A larger tracked sub-compact tractor than above is the Fort-IT Horizon

The Track-O Cross-Country is an electrically powered teleoperated tracked carrier with a flat top.

It has a run time of only 2.5 hours but can carry 1,039 kg on a flat surface, weighs 750 kg, its length is 1.84m, width is 0.76m, and height is 1.27m.

Carrying capacity is impressive.

With an appropriate gooseneck or fifth wheel type attachment, it could also be used for short-distance trailer moves.

This brings me to dedicated trailer dollies, also used for moving trailers short distances and with control and safety in mind, the kind of qualities needed when loading and unloading helicopters.

This is the Trax Trailer Dolly.

As can be seen by the video, the trailer hitch sits over the centre of the vehicle and can be electrically raised and lowered. It is 1.2m long, 0.74m wide, and 0.35m high. It weighs 150 kg but can move a 6-tonne trailer. It would need to be fitted with a NATO standard hitch.

One of the issues with long trailers is the ramp break-over angle, a levelling carrier platform could be used if fitted with a towing assembly. The Movex carriers can be fitted with a 45-degree lifting device that would enable the trailer coupling to remain level as the carrier moves down the helicopter ramp.

The Alma Levelling Crawlers are designed for moving heavy loads in tight spaces, with levelling platforms that work up to 40 degrees.

Mattro Ziesel

The Mattro Ziesel was originally developed as an off-road wheelchair, but it has been developed by some partner organisations to develop usage in agriculture, such as the Aebi EC-170 which has a front-mounted PTO.

With a 60-degree side slope, low ground pressure, and a top speed of 35kph, they are more mobile over extreme terrain than a quad bike ATV.

With a low centre of gravity, integral folding roll bar and four-point harness, they are likely to be much safer than a quad bike ATV and there is even a road-legal version.

Their towing ability is equally impressive, over 500 kg.

The vehicle is 1.32m long (plus 77 mm for the tow coupling) and 1.22m wide, height to the top of the ROPS is 1.62m.

Like all electric designs, battery life is a key limiting factor to employment, 3 hours for this one.

Hawe Mattro has developed a more compact version as a base platform for UGV developers, including Dhiel, as part of the Integrated Modular Unmanned Ground System (IMUGS) demonstration.

Although it only has three hours of endurance, and is thus not entirely practical, it is shorter than a quad and can tow more in more demanding terrain.

Howe and Howe did make the diesel-powered Ripchair a few years ago, but it seems no longer available or listed, which is a shame, that would have been interesting as a quad ATV replacement.

Still electric, have a look at Action Trackchair

Yanmar AC21

I am not 100% sure if Yanmar makes these any longer, but the diesel AC21 (and similar models) was a capable and compact machine

Weighing 830 kg, it was 2.33m long, 1.25m wide, and 1.82m high to ROPS.

It has a rear-mounted PTO so it could potentially be used with some PTO-driven trailers described above.

Loglogic Tooltrak

The Loglogic Tooltrak is a compact-tracked tractor and tool carrier

What makes the Tooltrak interesting is its short length, 2.48m including the front linkage. It has enough power to tow a 105 mm Light Gun and is short enough that it and the gun could be carried inside a Merlin.

At 2.149m high, it would be too high for internal carriage unless the cab was replaced with a folding ROPS. It weights 1.3 tonnes and the width over the tracks is 1.64m

The RNLI use them for lifeboat launch and recovery.

Landini Trekker 3 Compact

The Trekker 3 is a typical narrow crawler tractor designed for hill farming and where low soil compaction is desirable.

Its length is 3.05m, width is 1.28m and weighs 3.2 tonnes, not leaving a great deal of payload when flying inside a Merlin.

Chinook carriage would be more sensible, with a towed trailer taking up the available space and payload. With a slight modification to the trailer deck, the Log Logic PTO-driven tracked trailer above would just about fit.

Mach 4R

The quad-track Mach 4R has similar dimensions to compact wheeled tractors, but has much greater mobility.

Weight rises to 3.2 tonnes, but the towing capacity is greater than 10 tonnes (more than the helicopter payload).

Performance on slopes and in soft ground is excellent, and better on-road than might be imagined.

One plus a large loaded trailer would max out a Merlin payload, but the difference between one of these and a trailer and an ATV with a trailer is pulling power in poor terrain and the ability to use oversized trailers, a plant, or tipping trailer for example.

A 105 mm Light Gun (in travelling configuration) and Mach 4R would comfortably fit inside a Chinook, which would make for an interesting gun raid.

MTT

I wrote about this a while ago, and think it is quite an interesting and well-designed concept that sits somewhere between a tracked utility vehicle and a tractor unit, so in a section of its own in this post.

The MTT-154 is an electric all-terrain tracked ‘tug unit’ that can be used singly or connected, and operated as a ride-on or via remote controls, used to push, pull or carry loads and trailers.

One of the more interesting aspects of the design is the ability to connect multiple units for a greater payload. They can be connected inline (like a snake), side by side, or in a quad configuration.

The side-by-side configuration can also have a load bed platform between them, similar to the Milrem Themis. The difference between this and the Milrem unit is that the centre is not fixed.

Because they are only just under 600 mm wide, three could easily be carried abreast in either Merlin or Chinook and because they are only 650 mm high, three can also be stacked.

At 2.25m long, and triple-stacked, a Merlin could carry 18, maxing out the payload. One row, triple-stacked, would leave a couple of tonnes of payload and enough space for a 4m long trailer.

A Chinook could carry 27 units, with a couple of tonnes of payload margin, or combinations that include trailers.

When arranged down the centre of the cargo area as a stack of three, on either helicopter, it would leave enough room for seated personnel on the seats, 6 in a Merlin and 9 in a Chinook.

The unit is a single-track device, powered by lithium-ion battery packs. 1 battery provides up to 4 hours (35 km) of runtime, with three allowing up to 12 hours of runtime or a 105 km range.

With three batteries fitted, a single unit weighs 290 kg.

The system can also be used to supply export power for power tools or other battery charging.

Batteries can be quickly swapped, and unlike the two-wheel tractor, cannot be heard from 3 weeks away, top speed is also a more respectable 24kph.

A single unit can carry up to 250 kg on the load bed and tow 1.4 tonnes on a flat surface, reduced to 450 kg in extreme terrain.

The video below shows a double unit towing a ski trailer, the trailer could be used for seating or stores. This configuration would be comfortable for a Merlin.

No data tables and load diagrams in this one but will look at the combinations later in the series.