The JCB Fastrac is a high-speed agricultural and utility tractor that has an unusual ability to operate at higher road speeds than conventional designs.

Although it may be considered a niche design, with sales quantities estimated to be less than a thousand a year, it is made in the UK and its features might lend themselves well to use in defence roles.

Because it comes from a live production line and has a global support infrastructure, it could also be obtained with little impact and used as a model for rapid force expansion in times of acute need.

A Fastrac vehicle could provide interesting options for the logistics and plant area by combining the functions of some C and B vehicles.

I’m curious whether the Fastrac would meet the wider requirements with a crew pod or load bed.

The JCB Fastrac

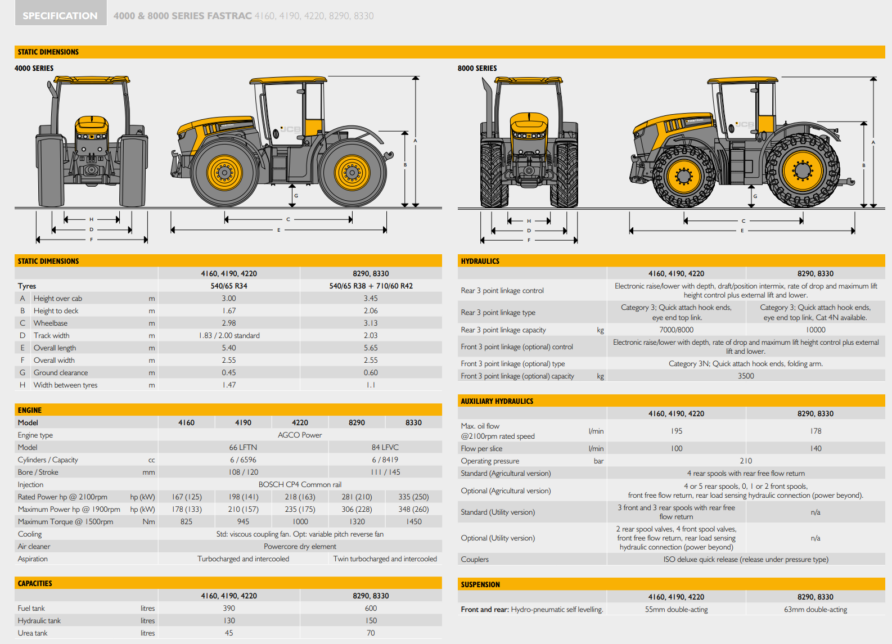

The JCB Fastrac is now available in two models, the 4000 and 8000 series.

The standard military Fastrac can tow 24 tonnes plus at 90kph.

A Fastrac tractor’s rear platform, which can be used for hydraulic crane loaders or as a load bed, is another factor that makes it so appealing.

This is not unique to the Fastrac, but it is not a common feature in other tractors.

Although a few years old, this video showcases the Fastrac road speed

As we have seen with many other similar vehicles, a protected cab is not a significant engineering challenge.

Tractors in Defence — Examples

The RAF has used the Fastrac as an aircraft tractor in the past, replacing the Unimog for Jaguar and Harrier operations.

There exist numerous videos on YouTube depicting the liberation of Russian tanks by tractors in Ukraine.

But you could say that both of these don’t make the case.

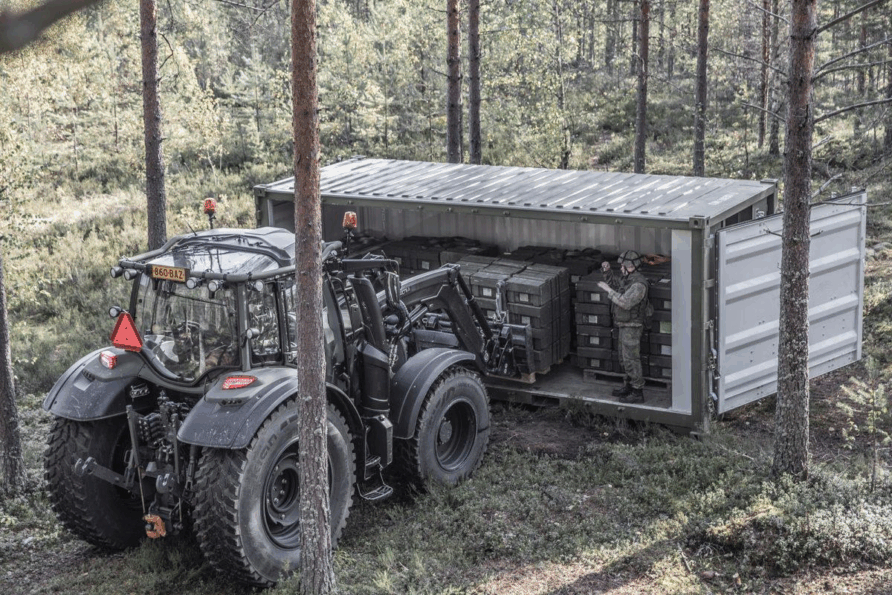

The Finnish and Norwegian defence forces equipped with Valtra tractors provide a more convincing illustration.

The Finnish Defence Forces ordered 77 Valtra N174 Active tractors and as many FMG hooklift trailers last year. In addition, the contract included front loader equipment, snow ploughs and graders. The N Series tractors were specified with front loaders, 57 km/h transmissions and cabs with rifle racks. The FMG trailers in turn were specified with a hooklift system that enables them to carry containers, pallets and other superstructures.

The ammunition, food and other supplies required by the troops are transported in the field in containers. The tractors can also be used to maintain the roads used by the troops in both summer and winter conditions, as well as to unload supplies using their front loaders.

They are used for logistic support

The tractor is equipped with a front mounted loader for pallet handling, with better off-road performance than telehandlers and fork lifts.

There has been excellent feedback.

Tractors have proven to be even more versatile than we previously thought. They have ploughed roads, loaded and unloaded loads, spun snow, laned roads, fortified and pulled loads in the terrain. Other types of weapons are also interested in tractors: the pioneers have used them in their own work, the artillery has distributed ammunition and dug pits with them

Colonel Jussi-Petri Hirvonen, ground forces maintenance manager.

The STM16E hooklift trailers are from the Farm Machinery Group (FMG)in Finland.

The hooklift ammunition containers have side opening doors that facilitate loading and unloading.

And for Norway

The Norwegian Armed Forces in turn have ordered between 25 and 30 new Valtra tractors. The models and specifications vary according to the needs of each garrison. The tractors are in the 100 to 160 horsepower range, and the contract includes an option for additional tractors.

In 2015, the Estonian Army also took delivery of several JCB Fastracs, providing a different use case.

These were equipped with hydraulic loaders and tipping trailers.

Estonia and Finland provide two distinct usage scenarios.

The Finnish example combines a tractor, a hooklift trailer, and a side opening hooklift compatible ammunition container. The tractor has a front-mounted loader, but there is no hydraulic crane loader.

Estonia opted for an arrangement that focusses more on combat engineering roles.

The tipping trailer can be used for moving a wide variety of defence stores, timber, and aggregates. The loader crane is also suitable for handling timber or aggregates.

There is no front mounted loader, instead, a surface blade and recovery winch.

The two approaches are not mutually exclusive, but they do demonstrate the different emphasis on either combat engineering or logistics support.

JCB Fastrac — Logistics and Engineering Support

A Fastrac is useful in two ways: as a tool carrier and as a towing vehicle.

Hydraulic Attachments (Rear Deck)

A rear deck mounted hydraulic loader crane can be fitted, available from many manufacturers.

Lifting hooks, log grabs, aggregate buckets, and even timber harvesting heads can be fitted.

For longer reach at greater weight, stabilising jacks can be fitted

It is also possible to utilize front-mounted stabiliser jacks, as illustrated below.

This is an interesting Fastrac development that uses a rear deck mounted loader crane.

But it is demountable.

Rear Load Bed

The rear deck can be outfitted with a small load bed instead of hydraulic tools.

The RAF Fastracs did just that.

The demountable loader crane in the section above can be replaced with a load bed.

Neat.

Hydraulic Attachments (Front)

The front hitch can also be used for hydraulic tools such as surface blades, winches, brush cutters and counterweights.

And with a track undercarriage.

The Royal Engineers are unlikely to be mowing verges any time soon, so a surface clearance blade and winch is likely a more realistic option.

A front mounted loader can be used for pallets and other attachments.

And in some cases, these can be combined with a front mounted blade.

Anti-Tank Mine Concept

This front and rear mounted concept for emplacing anti-tank mines is a great example of tractor flexibility (although not a Fastrac)

Available right now, off the shelf.

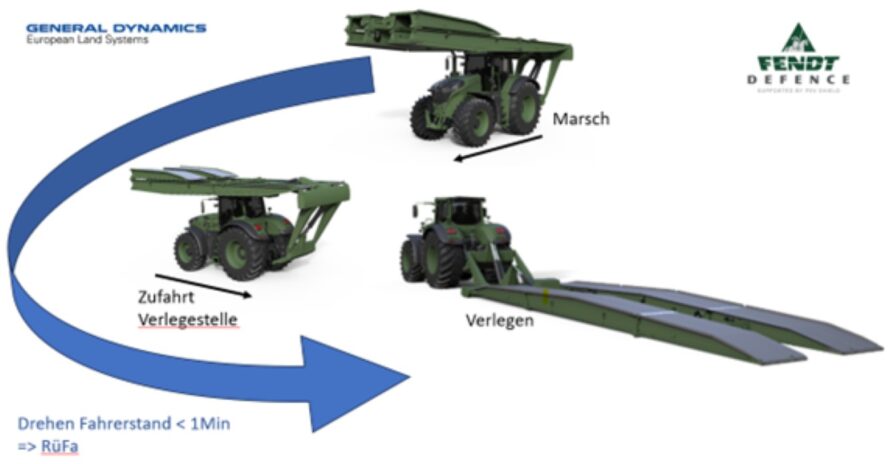

Bridge Launch Mechanism

In 2108, @easibridge and a few others had a chat about using a tractor as a launching vehicle for one of their lightweight bridge designs.

Fendt Defence and PSV Shield realised something very similar in 2024.

This used a Fendt 900 Vario, rear three point hitch launch mechanism from Pearson Engineering, and the GDELS COBRA Folding Bridge.

The image below shows the bridge support and counterweight.

Standard Trailers

As is the law, I am going to talk about trailers!

A simple multipurpose trailer can be used for defence stores.

A plant trailer can be used for even quite heavy equipment.

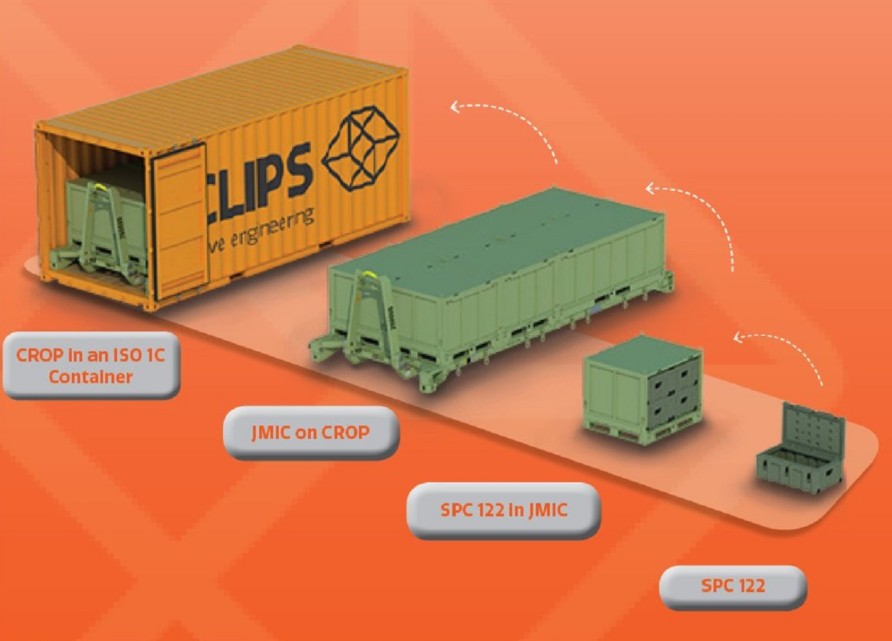

Or ISO containers

Tipping trailers can also be fitted with timber bolsters to extend utility.

Hooklift trailers allow use with various payloads, and some can also have tipping mechanisms.

Any hooklift compatible container or flat rack can be used.

This unlocks a great deal of flexibility.

Heavy lift trailers can be fitted with integral hydraulic loader cranes.

These are sometimes used for moving empty ISO containers.

Liquid trailers, although farm slurries, might not be useful for defence, water and fuel would be.

These can also be fifth wheel/gooseneck.

Put simply, any combination of trailers can be used.

Driven Axle Trailers

Trailers can be a double-edged sword, they certainly improve carrying capacity and flexibility, but they impinge on mobility.

In this use case, a standard Fastrac has limited utility without a trailer, so unless we simply accept the mobility trade off, some alternative option will be needed.

Although PTO driven axle trailers are available, a much more sophisticated design uses hydraulic motors to drive the trailer wheels.

At a slightly larger scale, HM Trailers in the UK make powered axle trailers, as do Pfanzelt.

Black Bruin in Finland and BPW in Germany the driving vehicle hydraulic system which provides the operator with much more control for the Agro Drive.

Powered axle trailers provide a significant mobility uplift.

Difco Trailers even make a tracked trailer with hydraulic drive.

JCB Fastrac — Utility Vehicle

JCB has used technology from Fastrac to form the basis of different vehicles, the High Mobility Engineering Excavator (HMEE) for example.

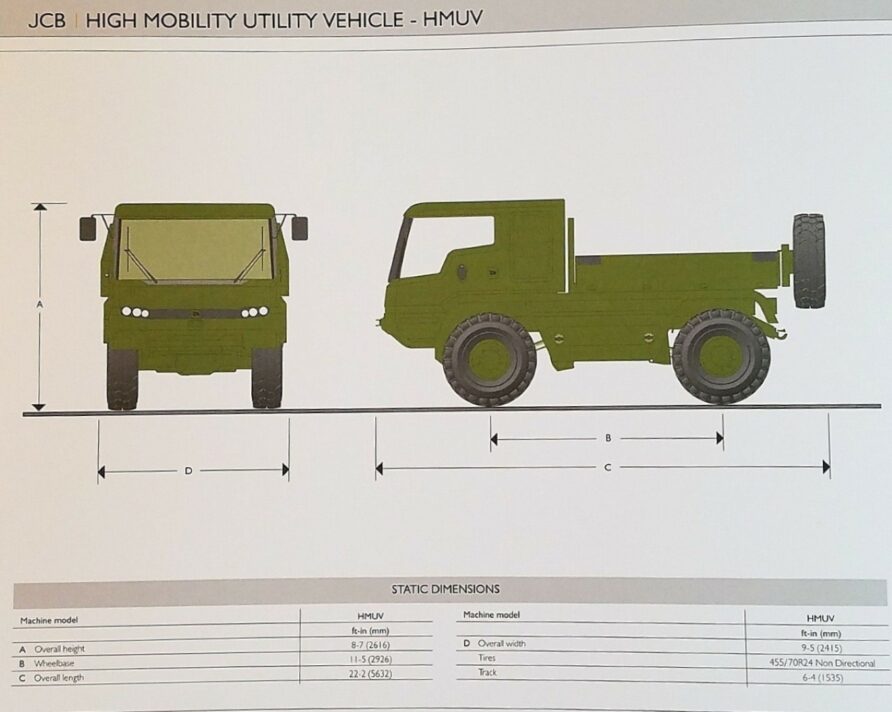

Closer to this requirement, the JCB High Mobility Utility Vehicle (HMUV) also used technology from the Fastrac, although a wholly new design.

Pop over to the Joint Forces site for a great review of HMUV, a quote from their article

Measuring 5632mm long by 2415mm wide, and with a cab height of 2616mm, the basic HMUV was of forward control design with a flatbed, dropside rear body. Its design payload was 4000kg, wading depth was intended to be 1500mm, road speed was quoted as being 65mph (105km/hr), and the suspension was dual level to give a high degree of mobility off-road while still allowing the vehicle to be transported inside a C-130 Hercules. The standard cab configuration was for two, but a double cab option to take six in addition to two ammunition pallets, was possible; one did not need a degree in rocket science to work out that this would make it an ideal airportable light gun tractor. A 6×4 version, giving additional payload capacity was also on the cards, and both armoured cab and armoured personnel carrier variants were under consideration.

There were no orders forthcoming for HMUV, sadly, but it shows the potential.

It also made a short appearance in one of the Captain America films.

Commercial adaptations of the Fastrac platform include a personnel transport version for shooting parties.

These are adapted from a Fastrac.

And many longer wheelbase models, mostly for agricultural applications.

Others have added another axle.

Although these are less common than the standard two axle versions, they demonstrate what can be achieved.

There are even forward control versions that maximise load bed length.

More recently, and as part of its hydrogen development programme, JCB has demonstrated a longer wheelbase Fastrac refueller.

Before instantly dismissing hydrogen as a military fuel, have a look at US Army analysis and testing, including explosive and penetration testing.

But that isn’t the point here, the point is that Fastrac is an adaptable design.

One problem that would have to be addressed is protection and crew seating.

Protection against blast would be assisted by the central crew pod position, instead of the seating position being directly over the wheels. It is good practice to have two personnel in each vehicle to provide overwatch, navigation assistance, and other functions.

Anyway, here is a long wheelbase three axle variant with ready-made counter UAS screens!

Summary

There are other tractor designs available, but the Fastrac is made in the UK, although much of the supply chain is European, as are New Holland models in Essex.

It has a couple of unique features that make it well suited to a range of defence applications.

But perhaps more importantly, it is churned out from a live production facility whose survival does not depend on orders from the MoD

If we use them now, we have a blueprint for using them if we need to rapidly expand, ploughshares to swords.

The JCM HMUV was yet another in a long list of missed opportunities for the British Army, timing perhaps?

That said, and however unlikely we will, I think the JCB Fastrac remains a worthy option to consider, either for logistics and engineering support, or with some development, as a protected mobility and utility vehicle.

To close, we could always use them for this!

Suggest you do your homework. The Fastrac was originally designed by JCB as a Battlefield prime mover.

Once upon a time FRES family was to include a. Bridging version. Am I wrong to assume that the mockup was based on this combo, mentioned in your article:

"With the Bridge Launching Mechanism (BLM) by Pearson Engineering the COBRA can be easily deployed by various multipurpose vehicle platforms"… And fully operated from under armour

?

Excellent article as usual. I worked with the Norwegian army in the seventies and as well as the BV202 they used a tractor which had a drop down wheel in the middle which enabled tracks to be fitted. Very good mobility particularly in the summer bogs. We had nothing to match it. I expect as it was a standard agricultural it could be fitted with loaders, snow ploughs etc.