Barbed wire and concertina are highly effective against both vehicles and personnel.

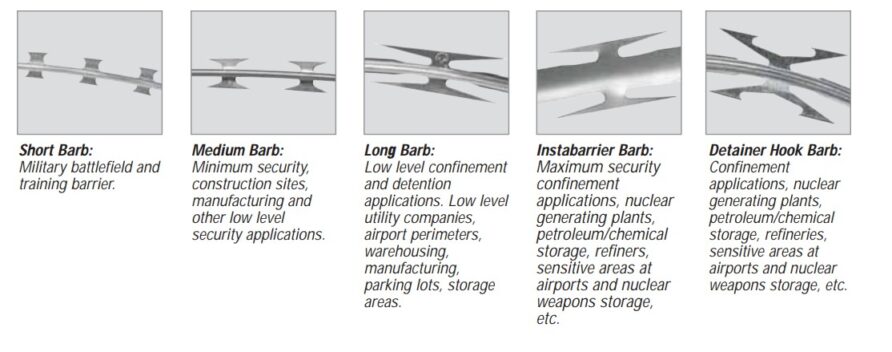

Types of Barbed Wire and Razor Wire

Barbed Wire

Barbed wire is a type of fencing wire constructed with sharp edges or points arranged at intervals along the strands.

It typically consists of two or more strands of steel wire twisted together, with barbs or spikes attached at regular intervals. The barbs are usually made from the same material as the wire, creating sharp protrusions.

Originally, barbed wire was made from iron, but now it’s predominantly made from galvanized or stainless steel to resist corrosion. There are also variations with coatings like PVC for additional weather resistance or colour coding.

The barbs can vary in shape, with common designs including the 2-point and 4-point barbs. The 2-point barb has two sharp ends, while the 4-point has four, making it even more deterrent.

The distance between barbs can vary, but typical spacing might be every 3 to 6 inches (ca. 15 cm) along the wire.

There can be single, double, or even more strands twisted together, with the barbs either welded or crimped on.

Razor Wire

Razor wire, also known as concertina wire or barbed tape, is a type of security fencing wire designed to be an extreme deterrent against intruders and as an anti-personnel obstacle.

Razor wire starts with a central steel wire core for strength and flexibility.

Attached to this core are razor-sharp metal blades or tapes. These blades are typically made from stainless or galvanized steel to resist corrosion.

The blades are usually flat, with sharp edges and points. Common blade designs include straight, teardrop, or round shapes, with multiple points or serrations to maximize injury upon contact.

Blades are spaced at regular intervals along the wire, often in a way that maximizes coverage and effectiveness. They can be oriented in various directions to ensure no easy path through the wire exists.

Short babe, to NATO Standards, are the most commonly used for defence applications.

High-grade stainless steel is preferred for its durability and resistance to environmental damage. Galvanized steel offers a more cost-effective alternative with good rust resistance.

Coils

Coils of both barbed wire and razor wire are used to create obstacles.

Coils of barbed wire are sometimes called Dannert Concertinas, each typically weighing 14 kg and useful for 14m of obstacle when uncoiled.

Coils of razor wire are typically called concertina tape.

Coils of both are available in various sizes.

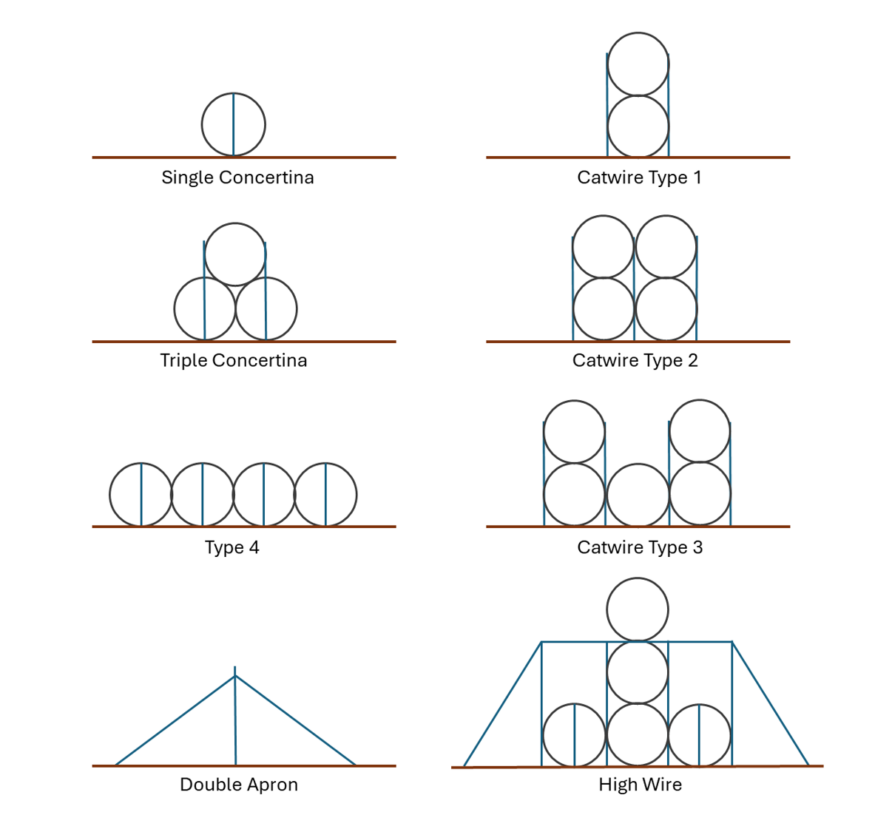

Obstacles using Barbed Wire and Concertina

Barbed wire and razor wire can be installed in different configurations, typical examples described below

- Low Wire Entanglement

- Single Concertina

- Triple Concertina

- Type 4

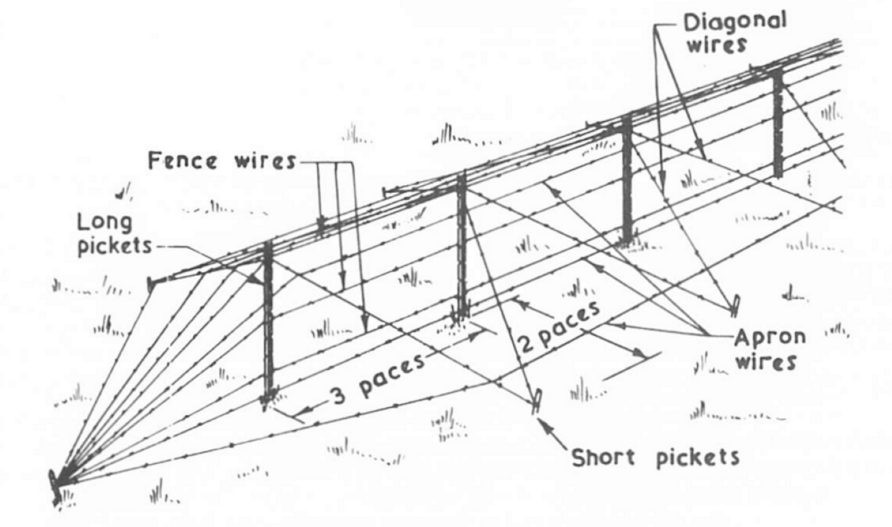

- Double Apron

- Catwire Type 1

- Catwire Type 2

- Catwire Type 3

- High Wire

Generally, either barbed wire or razor wire can be used in these configurations.

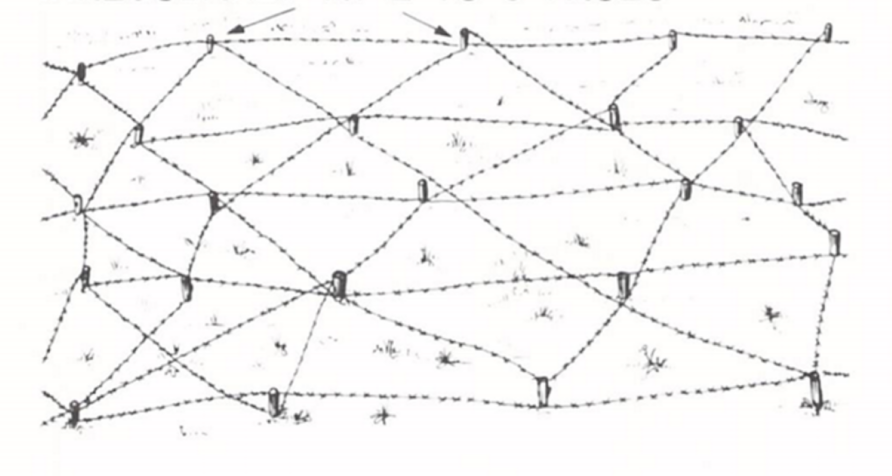

Low Wire entanglement

The Low Wire entanglement makes use of single strands of barbed wire and is most effective against personnel.

Pickets are usually placed between two and five paces apart, and it is very difficult to destroy with artillery.

Double Apron

A double apron is used to construct a barrier where no concertina coils are available.

Concertina

Concertina barriers are quick to install and can be built over long distances.

A single concertina can be used to create a quick obstacle during the preparation of more comprehensive positions.

They can also be used to top walls and fences.

Build

Tools for the wiring party are simple, cutters, leather gloves, windlassing sticks, sledgehammers, and a post driver (called a monkey)

The wire is secured using 0.6, and 1.8m notched steel pickets.

Typically, a 12-person wiring party can install 100m of single concertina in between 30 and 60 minutes, depending on local conditions, and assuming the pickets can be driven into the soil.

This 100m of single concertina will require 30 pickets and 7 coils, and a single 120m length of wire.

Defeat Mechanisms

Barbed and razor wire can be defeated using artillery, combat engineer vehicles, and explosives such as Bangalore Torpedoes, but like all obstacles, consumes resources, slows enemy forces, and signals intent.

High tensile wire is more difficult to defeat than mild steel.

One can imagine in the future, small drones or UGV’s will replace Bangalore Torpedo style defeat mechanisms.

Imagine a drone like the Malloy T400 carrying an explosive pack with pre-notched fragmentation liner, dropping it right on top of the wire.

Or two dozen of these, unloaded from a Boxer.

Who knows, maybe the wire grapple will make a re-entry!

New Products and Techniques

Before looking at shiny new things, we should ask whether the tried and tested techniques need improvement.

In many ways, the answer is no, but my view is always that anything to increase task throughput for a declining in size force should at least be considered.

Using wire and coils to create an effective barrier is not highly skilled, but there is technique, and for build teams to be effective, they require practice.

Can we exploit techniques, tools, and equipment from the fencing industry, and it should be noted that the labour-intensive methods used by the British Army (and many others) would not be used in that industry today?

Notched pickets being hand-driven and windlassing using a windlassing stick, not used a great deal any longer.

Flat Tape

Birmingham Barbed Tape, in the UK, makes a flat version of razor wire coils called BBT Flatwrap.

Electrocoil is designed to provide an intruder detection signal and high voltage shock, although not used in a military context.

MZP Patunka

Ukraine has deployed a tangle low wiring solution called an MZP Putanka, similar to that also used by Russia

This is quite effective, and note the lack of barbs or hooks.

Rapid Deploy Concertina

Deploying concertina is not common in the fencing industry, they are mostly the domain of defence and security, but let’s start there.

There are solutions from a few suppliers that allow concertina coils to be rapidly deployed, and these concertina coils are already pre attached to each other.

This video shows some of these rapid deploy systems in operation.

A forklift or all terrain telehandler variant can be used without the trailer.

Hundred of meters can be deployed in minutes, ready for securing (ideally), and this method could also be used from a suitable tracked carrier or high mobility logistics vehicle.

Atkore in the UK also makes something called a Hatbox, a plastic box rapid deployment system for 15m long barriers.

The HatBox is designed for military and police use in varying climates and terrain conditions. This unit can be rapidly deployed in hallways, stairwells, entrances and exit areas, etc. and quickly recovered for repeated use. Allied’s HatBox can be used in both indoor and outdoor applications. Each unit comes with all the materials and tools necessary for immediate use.

These would be excellent for creating temporary barriers in an urban context.

Posts and Ground Anchors

As seen in the images below, short pickets are used to secure the ends of concertina runs or when creating low wire entanglements.

The simple long picket takes some beating in terms of simplicity and durability.

Arguably, these two components don’t need fixing.

T Post is commonly used in the wire fencing industry, galvanized or PVC coated, and in various lengths.

For setting end posts, connectors can be used.

Fitting are available for T Post that allows a single person to unspool rolls of barbed wire, especially useful for terrain that would less suit conventional methods.

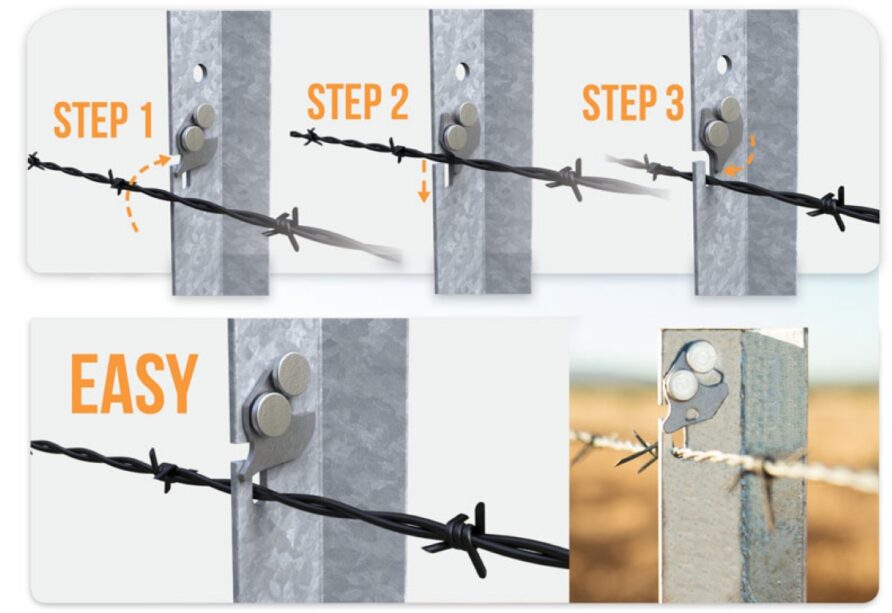

Clipex makes a Y shaped fence post with a special locking system for wire.

This would avoid having to wind barbed wire around the post as the run continues, saving time.

They are used with a fabricated end post.

Vineyard posts would also be another suitable option, galvanized or powder coated (especially when paired with some anchoring and tensioning systems described below)

The image below, from WWI, shows a wiring party carrying helical screw posts.

This type of post was used where the ground would not support conventional pickets.

Helical screw piling is commonplace as a concrete foundation alternative, but less so for fencing posts.

UK Helix do have fence post adapters for their system, though.

With mechanical assistance, screw piles can have a very pull-out resistance.

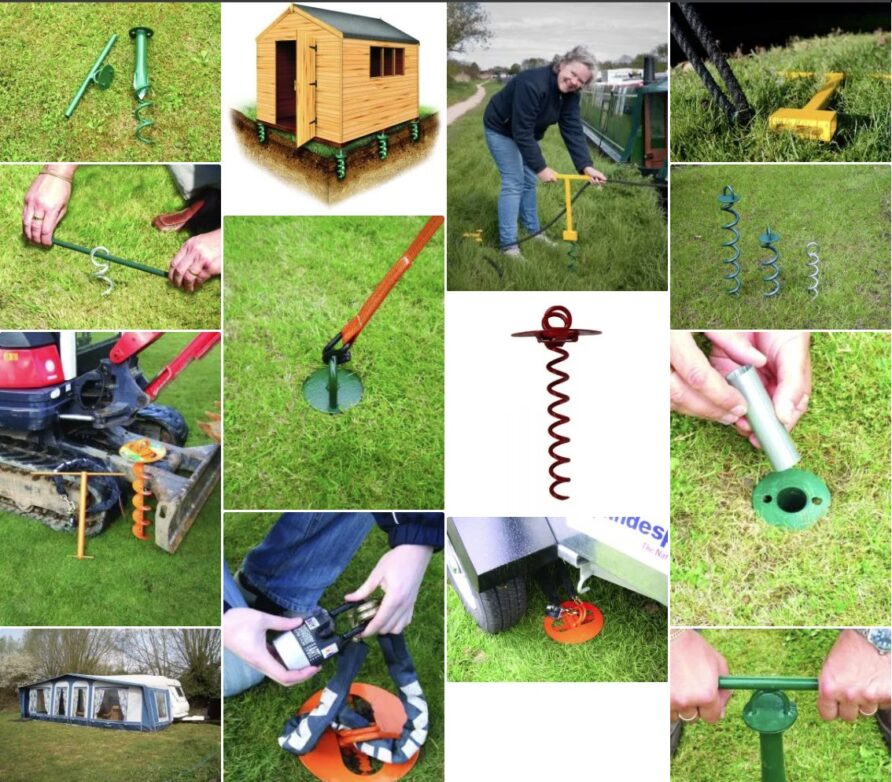

For smaller anchors, screw in types can be used instead of simply driving straight edged pickets.

These are used for everything from motorcycle security and awning pegs, to securing communications masts and scaffolding, available from many manufacturers.

Spyrabase in the UK is well known, at the lower end of the scale.

These can be driven by hand, or with portable battery power drill drivers.

Moving up in scale, another British company, Spirafix

They have a 10 mm hex head so can be driven manually, or with power tools and excavator attachments (at the larger sizes)

Once driven to depth, tethering brackets and eye bolts are fitted.

Available in a range of lengths and diameters, these are industrial class products.

Gripple and Vulcan anchors have an interesting set of products that use a pivoting anchor plate.

When driven (using manual methods or machines), the anchor tendon is drawn back using a specialist tool (Gripple JackJaw) to provide a firm fixing.

The video below shows how they work.

Rod, fibre, and wire rope tendons provide different load ratings.

Drivers

Sledgehammers are the most common method of driving pickets into the ground.

But, there are other solutions to make the job quicker, and much better suited to hard or frozen ground.

Hydraulic, compressed air or petrol-driven post drivers can be used to ‘hammer in’ either wooden posts, steel pickets or T Profile stakes to secure and reinforce corrugated steel or timber reverting, or provide secure anchors for barbed wire.

Manufacturers include Atlas Copco, Hycon, Petrol Post and Power Post.

With engineer support, post drivers would radically speed up the task, and allow the wiring party to do other things, or more wiring.

Petrol models are not particularly expensive and are hand portable.

The image below shows a model with the Clipex fencing posts described above.

Although civilian petrol (Gasoline) is not the ideal fuel for these, something like Aspen Fuel might be a strong option due to its long storage characteristics.

Hydraulic post drivers have the highest power levels, but need a hydraulic power pack or export facility.

For difficult ground, they are unrivalled, as described on the Designer Metal fencing website (video below)

The same range of hydraulic drivers can also be used with Spyrafix anchors.

Most of the systems above create undesirable noise, which will travel, especially at night.

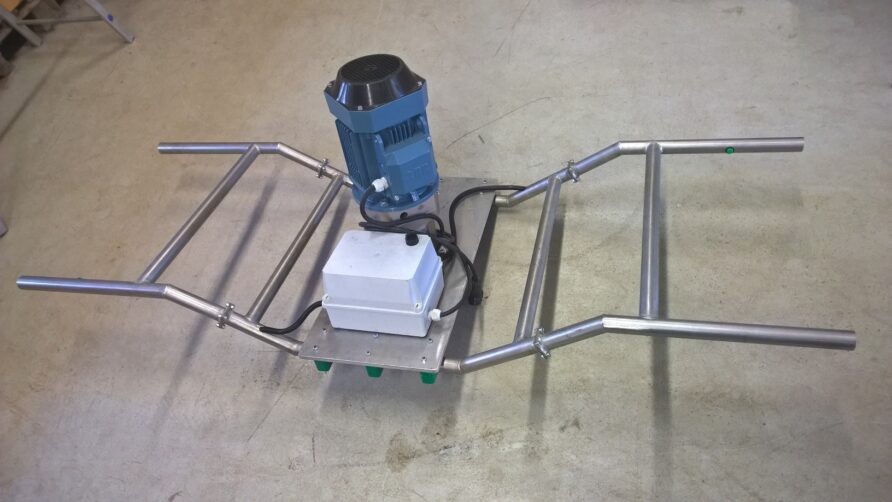

There are two low noise systems, helical screw piling from UK Helix (and others)

With sufficient power nearby, an electrical device can be used.

And if not, the manual driving adapter.

Both these approaches would work well, although the latter will be slower.

When using wood fence posts, there are manufacturers of vehicle-based systems, and ones that be operated as either an excavator or telehandler attachment.

And self-contained tracked vehicles as well.

Tensioning

Tensioning wires, our friends Gripple have options.

The video below shows the Gripple tensioning system in use with the Apex anchor

We could also use more conventional radisseurs to provide quicker tensioning at low cost.

Or we could stay with windlassing sticks

Hurrah for the CRE

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

"pre-notched fragmentation liner"

continuous rod and linear shaped charge warheads should be much more effective