Any physical obstacle can be breached, they are not force fields.

Anti Tank Ditches are no different to any other obstacle.

The reason they exist is to delay, frustrate, divert, shape, influence, canalise, and, absorb enemy resources.

To be effective, they must be under observation, and covered by fire.

Observation can mean anything from a pair of eyes to a UAS to an unattended ground sensor.

Covered by fire can mean a GPMG or GMLRS.

Properly constructed obstacles oblige enemy forces to use armoured combat engineering equipment, always in short supply. In exposing this equipment to fire, they will naturally be reduced in number.

Obstacles are rarely deployed in the singular, a well-designed barrier is a system, a collection of obstacles that exploit their unique characteristics and the natural environment to provide depth of coverage.

A definition of a tactical obstacle is…

Tactical obstacles are those placed in the enemy’s way to prevent or delay movement, to divide and disperse his attack, or to shepherd him into positions where he will be particularly vulnerable to attack.

Tactical obstacles can be designed to counter heavy armoured vehicles, wheeled vehicles, or personnel.

Outside the scope of this obstacle are security fences, vehicle checkpoints and portable obstacles used for public disorder control.

Obstacles can be natural or artificial, or a combination of both.

Also outside the scope of this post are mines, will look at those separately, but mines can form an integral component of an obstacle plan.

Anti Tank Ditches — Basics

Anti-tank or anti-vehicles ditches (or trenches) are extremely effective, if one has the time and engineering plant.

They can immobilise vehicles, absorbing recovery resources and making them vulnerable to attack.

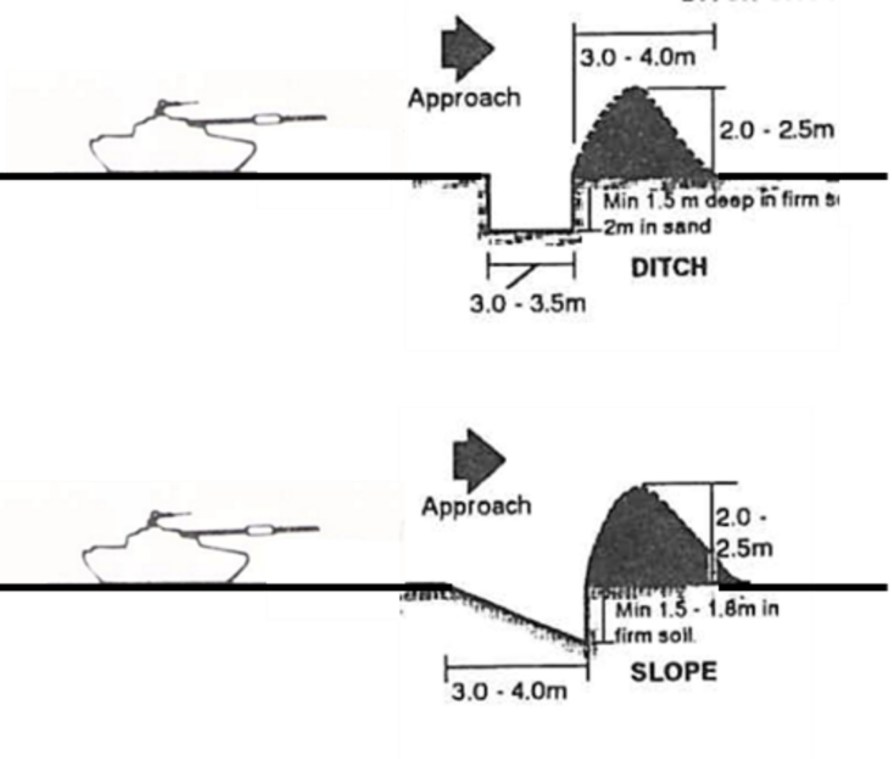

Different designs can be used, depending on local conditions and equipment available.

They can also be side cut into an incline, and in some versions of the slope design, the spoil is distributed on the enemy side of the ditch (although this can provide enemy forces with a convenient mass of material to bulldoze into the ditch)

Gaps in the ditch can be mined, or prepared for observation and fire.

Anti-tank ditches can be made to appear to be a simple personnel trench by undercutting the parapet and parados, and then using lightweight shoring that will collapse under the weight of a vehicle.

Undercutting preserves the integrity of the surface to reduce detection, but will take longer to create. Clear-cutting a larger ditch and then creating a fabric dummy surface might be quicker.

The image below shows a well constructed anti tank ‘trap’ or ditch outside of Tobruk during WWII.

Craters can also create an effective barrier to vehicles, created by artillery fire or deliberate demolition charges.

Ditches can also be combined with other obstacles.

With careful siting, approaching vehicles will be forced to slow down and bunch up, presenting a concentrated target area for ATGW or artillery fire, although with pervasive drones and other means of reconnaissance, this seems less of an advantage now.

An anti tank ditch can be singular, or in depth, with other obstacles (including more anti tank ditches)

Anti Tank Ditches — Construction

Anti tank ditches can be dug with conventional excavators and dozers, or combat engineer vehicles.

With dozers, the T Push method is one of the quickest, shown in the videos below.

And below, with combat engineer vehicles.

Where the ground is hard and rocky, demolition charges or ripper blades may be used to loosen the soil before excavation.

There is no substitute for power and blade width, anything less than 3m wide and the ditch will require multiple passes, considerably slowing down construction.

The Trojan has a blade with greater than 3m so is an ideal vehicle, but they will always be in short supply.

Terrier is slightly narrower than the Trojan, but still good for a single pass.

The British Army also has the Caterpillar D5N in service, again, with a 3m wide blade.

One can imagine a large autonomous dozer might be a path forward to increase throughput and protection for scarce resources like plant operators.

These are becoming increasingly common in the mining sector (more on this subject in the following post on digging).

Removing the operator from the task and putting them in an Ajax or Boxer vehicle is one possible way in which teleoperation (rather than true autonomy) might be a more practical proposition.

Even the super heavy pipeline trenchers from Tesmec and Mastenbroek don’t tend to go over a couple of metres wide, so trenching machines to do this are not available, or practical for defence use.

There are specialist machines used for canal excavation, from Allcons for example.

Hard to see these being used in a defence application, though.

Anti Tank Ditches — Longevity

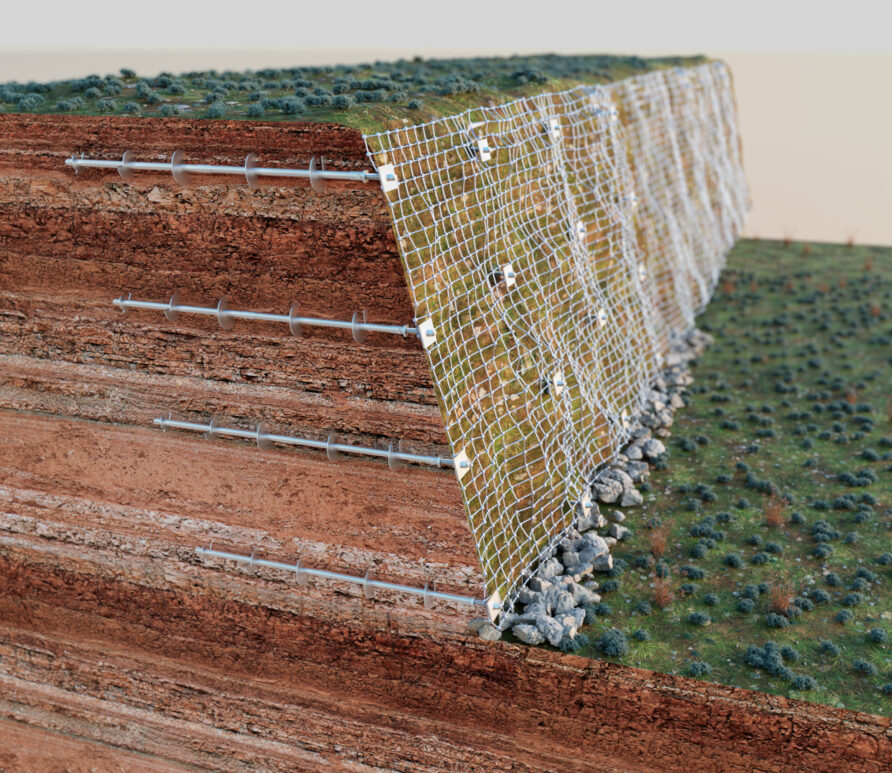

The sides will naturally erode over time, so, depending on their lifespan, will likely need some form of revetment or stabilisation.

Retaining walls can be built in a myriad of ways, with a bewildering array of techniques and materials, but the four defining features of retaining walls in an anti-tank ditch are…

- Length; they are likely to be several kilometres long, revetting or stabilising will be a considerable task

- Longevity and durability; generally, they will have a much shorter lifespan than retaining walls used in building and civil engineering projects, and no one will sue if there is a collapse

- Cost; solutions will need to be cheap, anything that consumes finite resources must be justified

- Construction time; it is likely that anyone digging an anti-tank ditch does not have the luxury of time, although there may be some cases where the opposite is true.

Like many conventional retaining wall solutions, poured concrete might be viable in some locations, but it is not a practical method for long distances. Traditional trench type revetment using driven posts and CGI would not be practical due to the amount of material required, neither would king post type techniques, these would be a major undertaking, moving from combat engineering to civil engineering.

Chemical soil stabilisation products might offer a quick method, and one that is ‘good enough’ for the potential lifespan.

Modern polymer based products are either sprayed on or injected into the soil, and react with it, creating a stable mass that resists water and freezing/thawing.

These solutions tend to be used for erosion control on slopes, not vertical surfaces, so possibly not that efficient, certainly one for consideration, alongside hydro mulches and fibres. This would depend on the angle of the ditch wall, even a slight deviation from 90 degrees will be much easier with chemical solutions.

If a physical solution is required because of soil conditions and other environmental factors, fast systems like geotextiles and ‘soil nailing’ might be worth testing, again, the term ‘good enough’ has to be front and centre. Soil nailing is often used with steel weldmesh and shotcrete, closely spaced.

A variation on this is to use geotextiles or meshes, with retaining helical screw soil anchors.

This technique requires specialist machinery to drive the anchors.

Instead of helical anchors, the Vulcan or Gripple Terra Lock systems provide tensioning force.

These are potentially more useful due to speed and low cost, although not shown in the video, can be used on slopes.

Perhaps worth a try, as would Concrete Canvas.

Anti Tank Ditches — Defeat Mechanisms

A ditch without the requisite dimensions can be defeated by brute force (especially in soft soil) or at speed, as demonstrated by this video.

Ditches can be breached with bridging equipment.

Fascines.

Or simply bulldozed in.

Think Defence is a hobby, a serious hobby, but a hobby nonetheless. I have removed those annoying adverts, but hosting fees, software subscriptions and other services add up.

To help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

You can click on an affiliate link, Buy Me a Coffee at https://ko-fi.com/thinkdefence, download an e-book at https://payhip.com/thinkdefence or even get some TD merch at https://www.redbubble.com/people/source360/

Youtubers, if you are going to lift content from here, the decent thing to do would credit me

Happy New Year.

A post without mentioning ISO containers? A deep enough ditch and an ISO container would make an ideal fascine. :-)

Great post TD.

Did the RE plant troop commanders course in early eighties. Because of the rate of urban development in North Germany, Anti-Tank ditches were height of fashion at the time, the course was visited by Commandant of RSME for the first time ever.

RE procured special buy of tracked excavators only to find that on the low loaders they snagged the German autobahn bridges.

Pushed relieved face design with a sloped entry and vertical wall on home side.

Old

Things

Still

Work.

First sentence looks funny, as the advert was not 'giving way '

Would be really interested to see a breaching tank used in The GW… To great success, as I don't believe many others than the US had maintained such in inventory.

DJV and Pekka, nice to see you back gents!

I don't think AT ditches are anything close to worth the effort.

They're super easy to detect & identify, armoured forces have fine navigation ability, neutralisation by bridgelayer or dozer is too easy. You can even neutralise such an AT ditch by shooting HE with delay fuse setting into the opposing bank.

43 Plant Sqn RE – Onsabruck – The AT Ditch Kings

The Sqn was the counter mobility assett for the Div(s).

The art of AT/ Veh Ditch construction is not fully covered in this post – some fundamentals missed.

The most effective means of AT ditch construction is by excavator – Hymac 201 (2.2m2 bucket) – Heavy Crawler Excavator (HCE) These HCE (2) with addition of Terex 82-30 Dozer – Heavy Crawler Tractor (HCT) (2) where transported on Seddon 37ft loaders.

This capability reduced with close of BAOR / BFG then transferred to the Border Crossing Points (BCP) on the border of Northern Ireland.

Counter Mobility – AT Ditches – A lost Art

Thanks AJS and welcome to the site, I will add that into the body in a future edit of thats OK?

Hi TD,

Pls put a note when those edits are in,

Thx