Continuing my look at defence shelters, this post looks at larger shelters, both prefabricated, and built in-situ.

The defining feature of the MEXE Shelter, in the previous post, was the nature of its construction, a compact kit of parts that could be readily transported.

Compact and efficient, but they would be limited in overall size and clear span length.

In this post, larger underground shelters.

Larger underground shelters (bunkers) can be used for higher level command posts, vehicle and ammunition storage, data centres, first line equipment support, personnel rest locations and medical facilities.

They are still not fighting positions, although they may come under attack.

It is assumed they will need to be concealed, and constructed in a manner to protect their occupants from enemy fire.

The degree of concealment and degree of protection could vary, but a bare minimum would be shell splinters, small arms and FPV type small drones.

They will require a combination of prefabrication onsite construction, and generally, more engineering support, time, and resources.

I also make the assumption that they will not be permanent, built and abandoned as needed, or if possible, moved.

Constraints

Transport resource, skills, cost, ground conditions, protection, means of entry and exit, and longevity, all place constraints on design and build.

Perhaps the most important is the length of roof clear span, the longer it is, without some form of pillar or support, the more difficult the roof challenge.

Burial for protection will create a significant load on the shelter roof.

Unsupported roof span and height will determine construction technique, prefabrication, or build in it situ.

Depending on the water table and other factors, a constructed floor may also be desirable, rather than compacted earth, aggregate, or some other free floating material.

It is also important to note that the British Army is subject to UK health and safety legislation, particularly CDM Section 22

There is no getting away from this, and neither should anyone want to, excavating trenches and larger voids is dangerous (with many fatalities due to collapse) so it is not a subject to be taken lightly.

Some images below show excavations that may not be in compliance, they are shown for illustration only.

A competent person would determine the protection scheme, usually involving some form of support, or battering. Battering is a term used to describe excavating the sides to a safe angle of repose (this can also involve terracing).

Options — Prefabricated Shelters

Prefabricated shelters have the potential for rapid onsite installation, but transport will not be efficient as the user is moving fresh air.

Their size will be limited by available transport and mechanical handling equipment.

The most likely practical size limit is that of a 20 ft (ca. 6 m) ISO container, or similar (even if not specifically an ISO container)

The build technique is pretty simple, dig a hole, and perhaps create a sub base with aggregate, drop the prefabricated shelter into it, use the excavated material to backfill and provide additional top cover.

Many can be linked together.

Prefabrication also allows internal facilities and systems to be designed and built in before use, saving valuable time.

Burying an ISO container might be considered a quick and easy method of creating a prefabricated buried shelter, but they are not designed to carry weight across their top surfaces.

When normally stacked, their weight is transferred through the corner posts.

If containers are buried, they will still need a roof beam and deck or some other means of internal reinforcement to support the overhead backfill material, or they will collapse, and collapse much quicker than expected.

Industrial Refuge Shelters/Chambers

Mine, tunnelling, and petrochemical facility refuge shelters are not designed for direct burial but focus on blast and fire protection, whilst providing a self-contained and safe breathing environment for miners, plant workers, and other personnel working in hazardous environments.

They would not be completely applicable to this requirement without modification, but their manufacturers would provide valuable insight and expertise, especially on environmental protection and inside atmosphere monitoring.

The example below is from Mine Arc in Australia

Mine refuge shelters have to be transported to their locations, and often moved within them.

Forklift slots and lifting lugs are all common features.

Some have hook lift attachments.

Suitably adapted for defence needs, these would be an attractive option, especially those with trailer components to allow easier transport.

They would also be able to be used above ground, inside industrial buildings and warehouses etc.

Civilian Bunkers and Basements

A niche market, but prefabricated underground shelters are available from suppliers, and they can be quite complex and well appointed.

This example is from Ultimate Bunker in the USA.

Each can be linked to form a larger space, using relatively common construction equipment.

Burrowed, in the UK, manufactures a range of buried prefabricated sectional steel shelters.

Atmas in Finland likewise.

The Modular Basement Company, in the UK, uses prefabricated pods to create basement rooms.

Adapting these designs would also be an attractive option.

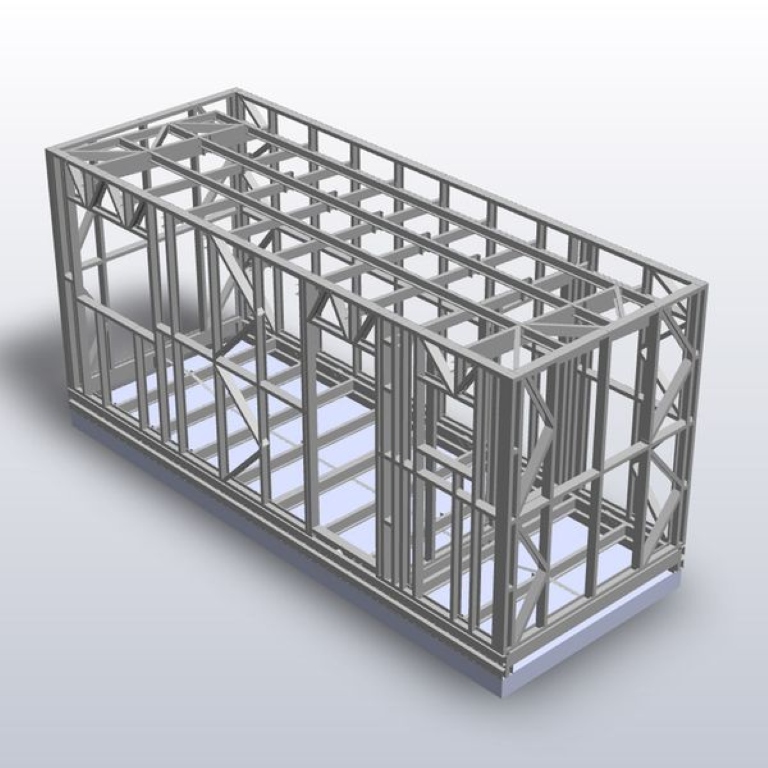

Bespoke Military Shelters

The British Army has recently taken delivery of a some expanding container command posts.

Although when buried, the expanding component would not be used, the basic architecture and internal fit out work has already been completed.

Instead of conventional containers, the next iteration could make use of an internally reinforced design, together with linking kits instead of expanding sections.

In Ukraine, Metinvest has delivered many hundreds of tubular shelters for the armed forces, a good example of prefabrication in a defence context.

These are built to a Soviet era design but have proven to be very effective and low cost, 165 ‘man-hours’ to produce and requiring 2 tonnes of steel.

Simple roll forming machines and hand tools are all that is required for fabrication.

They are used for command posts and personnel rest areas.

The shelters can be disassembled or transported ready built.

And when on site, lifted into place with mobile lifting equipment.

Building on success, Metinvest has also started to produce medical facilities in the same basic format.

Whilst strong and requiring less material to build, tubular shelters sacrifice some internal volume when compared to a rectangular profile.

Build In-Situ

Building shelters onsite is likely to require fewer transportation resources than prefabrication for a given shelter volume, due to not needed to transport fresh air.

Larger shelters can also be built using this method, but regardless, building will generally take longer than installing a prefabricated solution.

Building onsite can also make use of locally available materials or to designs that accommodate ground conditions and specific requirements.

I have excluded conventional formwork and poured reinforced concrete for the options below, these would be too time-consuming unless being built as part of a national preparation effort.

Frame and Revetting

With suitable timber and steel components, larger shelters (with larger clear spans) can be constructed.

An example of this technique from the 3rd Combat Engineer Regiment in Australia is shown below.

Excavate (note the battered back walls and terracing)

Build with timber, steel box section, and corrugated steel for revetting.

Add sandbags, geotextiles, and backfill

Longer spans and a more spacious layout are enabled using steel box section.

Additional protection for entrance areas could be provided by Hesco Bastion (or similar) and C-UA mesh or netting.

Similar, is this example from Ukraine

As can be seen, there is extensive use of timber and logs, together with geotextiles and steel fencing mesh for revetment.

I would also note the entrance layout to minimise blast propagation.

Timber frame construction can utilise rough sawn lumber as revetment, especially useful if this is locally available (e.g. in heavily wooded areas)

The example below is from Finland, although arguably does not qualify for this post due to its relatively small size and span length.

Gas, compressed air, and battery-powered nail guns, nailing plates, and other fixing methods speed up construction significantly.

Round logs can be used, but wasteful of material.

With a timber frame, walls and a roof will be needed to (obviously) complete the shelter.

Corrugated roofing sheets are ideal, although wood can also be used, with a suitable non-permeable membrane.

I have included this method here because it shows an alternative to steel framing, but as can be seen, it would require considerable time to build, and more personnel resources.

Hesco and Defencell can also be used for wall construction for semi buried shelters.

Tube and clamp systems (later in this series) could also be used to create the internal frame.

For longer spans, castellated beams or deck trusses are used.

With geotextiles or sheet revetting, and waterproof membranes used to complete the construction before backfilling. A slight fall on the roof might aid with water run-off.

This type of construction is economical, and can adapt to the surrounding environment and threat landscape, but is relatively slow to build.

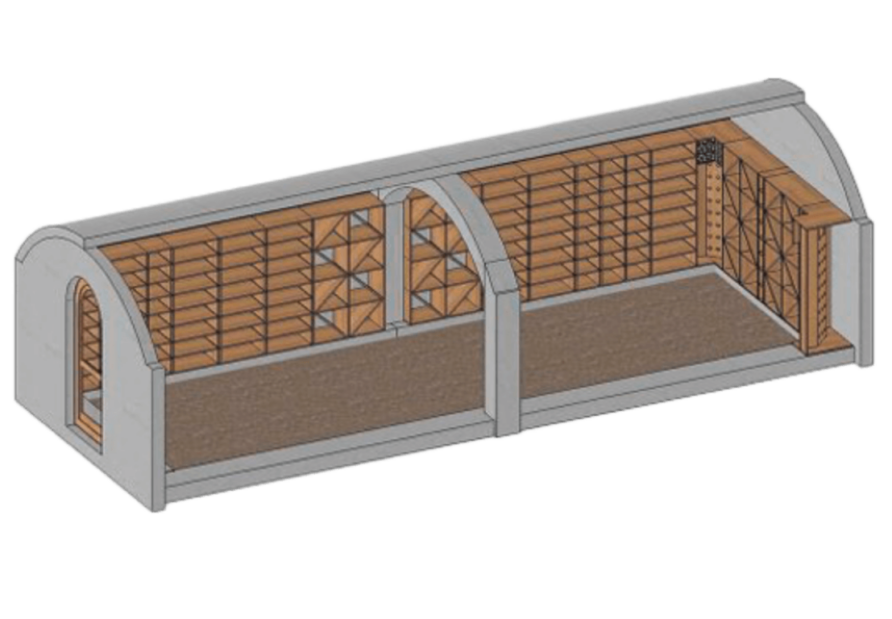

Continuous Section Concrete Culverts

Precast concrete sections are strong and durable, and can be used to form complete structures that can be deeply buried.

When buried, box culvert sections would provide an effective shelter with large clear span and good ceiling heights.

Because of their weight, high-capacity mechanical handling equipment would be needed, which makes them a less practical option. And even a modest size shelter will require many large truck loads, and unless battered back, the trench will need considerable shoring.

This is a good video that shows a typical construction and sealing process.

Some shelter manufacturers make use of concrete culvert sections, as shown in the image below.

Sectional Concrete Culverts

Instead of a single continuous ring, sectional pre-cast concrete culverts could be used to provide slightly improved transport efficiency and easier handling.

Instead of box culverts, pre-cast arch sections like the ArchLok could be used, although it would be a significant construction project.

These create strong and potentially large shelters, able to withstand a serious pummelling if buried deep enough

But they have the same problem as box culverts, they consume a great deal of transport and build resources, and are hardly quick.

More of a civil engineering solution rather than a combat engineering solution.

Pre Cast Concrete Shelters

Although a niche market, there are many examples of prefabricated root cellars and storm shelters, but how about a prefabricated underground wine cellar, the most Frenchest thing ever!

The 4.3m × 2.4m Jeroboam Cave costs less than £29k, and can be installed quickly, using a single truck with integral crane.

Larger versions are available, as are joining kits

A waterproof membrane is used before back filling.

Swap the wine for more defence oriented items, and the utility is obvious, and the fact they don’t require large cranes makes them even more attractive in a defence context.

Steps, ramps, and other means of entry and exit would need to be included in the designs.

If large and robust are key requirements, precast concrete sections are a good means of meeting them.

Interlocking Concrete Block Arch

Lock Block (in Canada) makes use of interlocking concrete blocks, but instead of being used for vertical walls, the blocks are tapered to create a segmented arch.

With these, no separate roof structure is needed, and the small block size makes transport and handling much easier than the larger concrete sections described above.

Installation will require less substantial handling equipment than the larger precast panels, including the interesting Zipper Truck system.

Video below.

This has been demonstrated to enable the building of over 400m of arched structure in less than 24 hours, without using large cranes or large installation teams.

A 6m version is also available, both equally strong.

Wall and Roof Construction

To improve transport efficiency, separate wall and roof approaches can be combined.

Concrete blocks have many advantages over larger precast concrete systems. MEXE experimented with an earlier version of concrete blocks for shelter construction in the seventies and eighties.

More recently, the construction industry has developed and introduced a type of concrete block with an interlocking feature.

They look exactly like what they are, concrete ‘Lego’.

Different sizes and designs are available from various manufacturers, but they are all used in the same way.

No cement is required for jointing, and walls are immediately available for use.

Transport to site can be done with different truck and trailer combinations.

Various methods can be used to lift the blocks into position, some have cast in threaded inserts, others can use a lifting clutch with a steel insert.

Excavators, fork lift trucks, telehandlers, cranes and loaders can all lift and position these blocks.

Block grabs and brick stack grapples are also used.

These have several advantages over the larger concrete sections described above. There is less open space to transport, and are much easier to handle with in-service equipment.

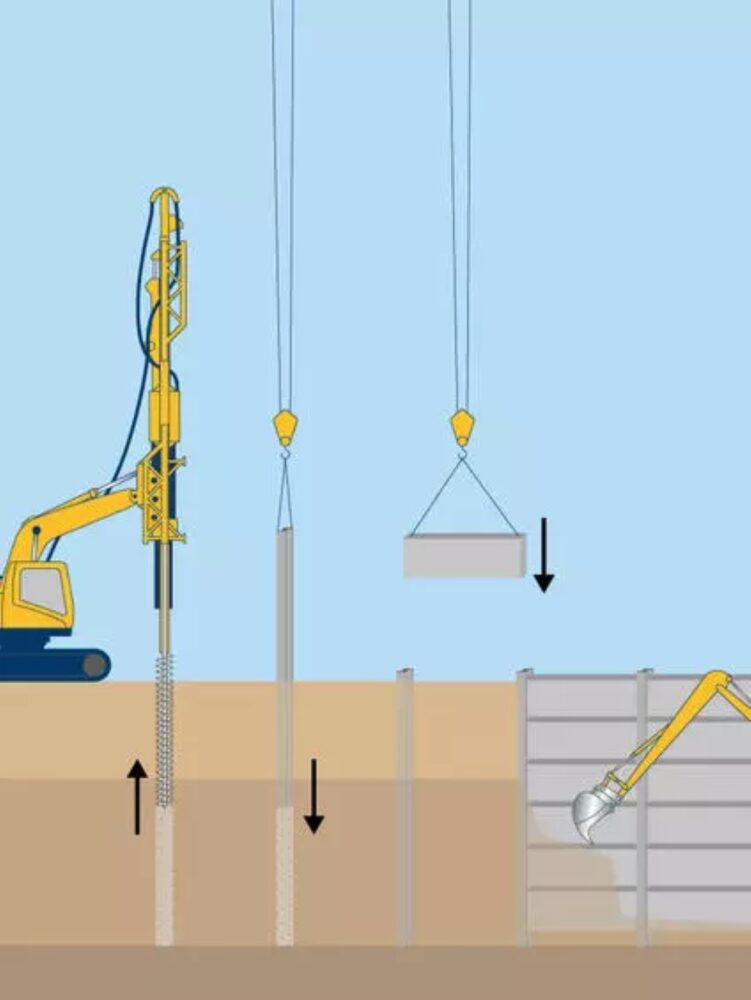

Perhaps getting into more permanent construction techniques, king post (sometimes called soldier piles) and retaining/lagging walls conventionally use a continuous flighted auger to bore a hole into which concrete is poured.

A H beam is inserted, the piles checked for level and alignment, and left to cure.

When the concrete is ready, the space between the webs is filled with concrete panels or sleepers

A similar approach is used to excavate from level down to grade, shown below in the video.

The piles are driven, and then infill added as the void excavated, moving along in turn.

There are variations that dispense with the pre-augering and concrete stage, and simply drive the beam into the ground using a vibratory excavator attachment.

Panels are inserted into the webs as conventional methods.

Like king post wall, sheet piling is a conventional construction technique, but one that is likely to take several days.

Plastic piles, with our without mandrels, offer a quicker and lower weight solution.

Because retaining walls built with this method often have to be vertical and have limited horizontal support, they tend to be strong.

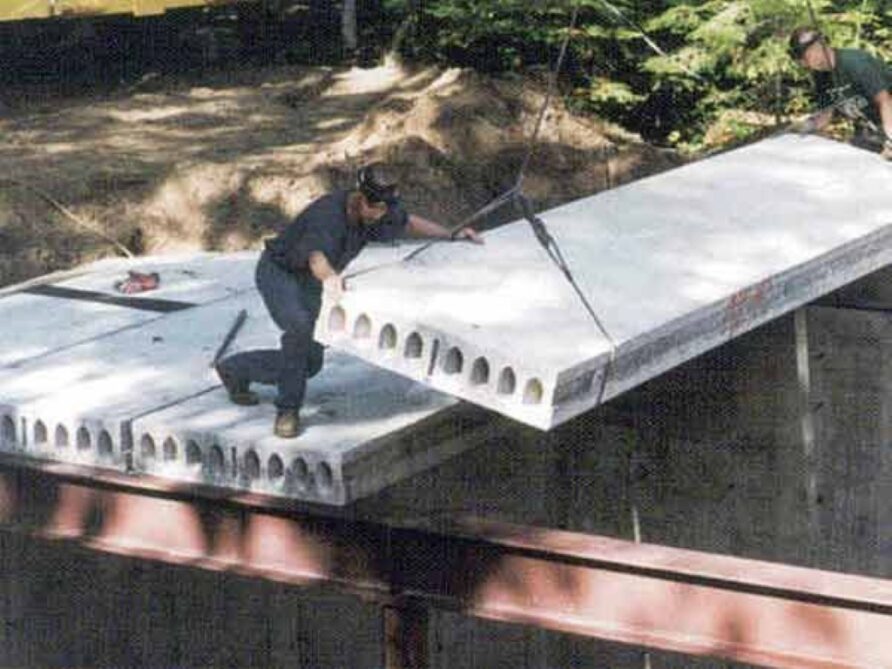

With the wall systems described above, they will all need a roof.

Concrete beams and blocks, or larger precast panels could be used.

With suitable lifting equipment, and a waterproof membrane, these could be relatively quick to install, resting on wall tops and secured as needed.

Longer roof joists, again, are available in a plethora of designs.

From solid timber and steel beams

To engineered open web joists.

Lightweight long span warren type trusses.

And castellated beams as shown below.

An alternative to flat roof systems is a corrugated steel arch.

The image above shows a corrugated steel arch on top of a conventionally poured concrete base, interlocking blocks could also be used.

All or any of these techniques could be potentially used, balancing robustness and weight, installation resources and skills required.

Telescopic or fixed ladders, prefabricated or scaffold system steps would also complete the installation, even including scaffolding lifts is casualty movement was needed.

Summary

Many of the NATO/Russia border nations already have extensive build programmes in place for medium to large underground shelters, and arrangements with landowners and civilian building contractors.

Without making facile Maginot Line comparisons, they are a sensible component in a mosaic of defence measures.

To what degree should the British Army be prepared to build them, though?

Like any capability, it must justify itself in a crowded equipment programme and busy training calendar, and one might argue that the kind of positional warfare that is now self-evident in Ukraine might be a useful model to learn from.

As with all lessons from Ukraine, we must be wary of learning the wrong ones or thinking they apply to us.

Positional warfare is inevitable as we run out of space or ability to manoeuvre (log, terrain etc).

There is a trend toward longer campaigns becoming more like siege warfare if one side doesn’t have an overwhelming advantage.

If we assume getting underground is desirable in many scenarios, the complicated task faced by designers is to generate a range of optimised designs that balance cost, skill, materials availability, ground types, protection requirements and transport availability.

Perhaps the biggest impact on design is the unsupported span distance across its shortest dimension.

Two to three metres width allows prefabrication, simply because 2.9m is the overall maximum permitted width of a vehicle without moving into abnormal load regulations.

An ISO container is a touch under 2.5m width.

To visualise the likely range of sizes of a prefabricated shelter, think of shipping containers (even though shipping containers are not suitable for burial)

If one has the luxury of time to prepare, can accept width constraints, and have and transport resource, prefabrication has many advantages.

First, onsite build can be very fast, dig, place, and backfill.

Second, installation can be completed without specialist skills.

Third, interior fit out can be completed and tested ahead of time, especially useful for complex shelter requirements like CP’s or medical facilities (although this will increase weight and make handling more difficult)

Stocks can be built up over time and stored in readiness.

Unless the clear span requirement exceeds 2.9m, absolute low cost, or some measure of customisation is required, prefabrication is more challenging and building onsite becomes attractive.

Significant problems arise when higher or wider structures are needed, but these should be an exception.

Large stores or vehicle access are the most likely requirement, shallow ramps and blast doors would be components, with construction using combinations of those described above.

Necessarily, these will require more engineering expertise, but that is what the Royal Engineers and Engineer and Logistic Staff Corps are there for.

We can do this.

A modest programme, that involves low-volume but sustained purchasing of prefabricated shelters and stockpiling at key forward locations, does not seem an outlandish concept. Neither does a documentation pack that includes video instructions to avoid having highly skilled civil engineers on each site.

For the larger shelters, a design, and test programme, with NATO (especially if we are thinking about ARRC HQ survivability) should be a priority.

Maybe some modest stockpiling, identification of manufacturers and storage locations that can be used in times of heightened tension, and maintaining a design library.

This is also achievable, none of this is cutting-edge science.

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

Yay! Three extra points for mentioning ISO containers. I would have been worried if you hadn't at some point.

I like to make sure every post has at least one mention!

A benefit of going underground is to make it harder for an enemy to locate. This should be taken into account when considering construction methods as a bloody great crane would probably give the game away.

On Operation Desert Storm (Granby), we came across many Iraqi positions which used buried isocontainers which had been looted from Kuwaiti freight depots as shallow protective bunkers. They worked in many ways. I note your concerns about their strength, but they do have considerable advantages, are abundant and easily transported.

The fragility problems can presumably be addressed with experimentation around modular reinforcement components. As a surgeon, I am particularly concerned to see the principles of going underground at speed and scale applied to the medical care chain. The critical element then becomes the ability to dig holes in dry ground at speed with adequate excavation and adaptation kit such as protected entrance modules.

I'm surprised you didn't mention concrete canvas this time. I remember them from an older post and I think you showed an inflatable bladder to hold their form during construction, and this became a waterproof liner that created a bright, clean environment.

Next in the series Paul!