Sandbags and gabions form an essential and enduring component of field defence capability.

Sandbags

Sandbags are not new, their use as a weapon or training aid goes back to medieval times, but arguably, as a field defence they were not widely used until the early 18th century

As muskets emerged as common weapons, sandbags were used, like gabions, wherever a quick and simple means of protection was needed, here at the 1781 Battle of Ninety Six in South Carolina. The 1854 Battle of Inkerman, especially the action at the Sandbag Battery, were notable.

Since then, where portable defence against shot and shells were needed, sandbags were there to be found.

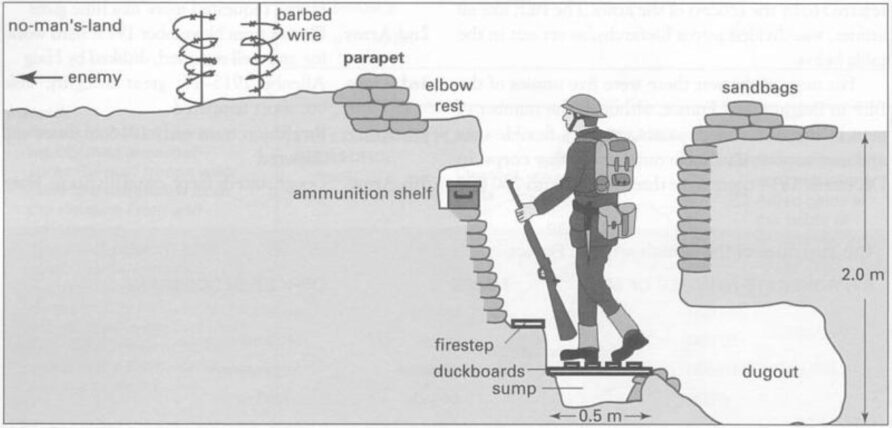

Their use in trenches is generally for revetting the walls and providing additional protection for the parapet (front) and parados (rear). In above ground uses, they constitute the revetment and can be used for overhead protection.

More recently, hessian has in some cases given way to synthetic materials, but they are still widely used, in some instances perhaps more impressive…

Than others!

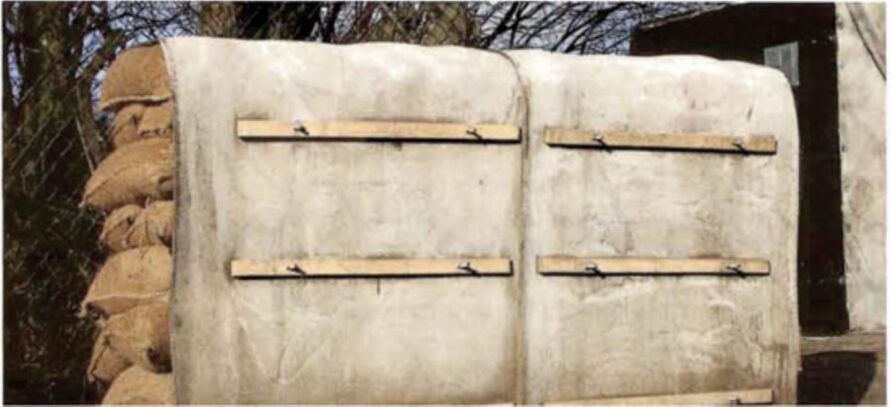

There is quite a bit of science behind sandbags, but the principles remain fairly simple, don’t overfill, lay in a bond like bricks, chokes tucked in, tamp down, tie in and slope back.

As shown by Sgt K, a reserve soldier from 170 Works Group here, an artist beyond compare.

Filling sandbags is not complicated, and the same method has been used since sandbags were first used. Someone holds them open, and someone else fills them using a spade or shovel of some kind.

Approximately 20 bags per hour is a reasonable output rate.

There are better ways, equipment, and techniques that maximise fill rate either with manual or mechanical approaches.

The most simple is to use a traffic cone.

Slightly up market from a traffic cone is the Sack Maker, at forty quid, probably not that much different in cost to the traffic cone!

Purpose made devices are also available, like the BCB International Sandbagger.

Compact when folded, and weighing less than 25 kg, the Sandbagger can increase fill rate to approximately 90 per hour.

The Sand Hopper is a similar design.

To really increase the fill rate, mechanical assistance is needed.

In the image of the BCM Sandbagger above, the caption indicated that the group filled 1,500 sandbags in an hour.

The Sandmaster from Barrier Systems in the USA is a simple attachment for skid steer or backhoe loaders.

The larger Sandmaster 26, as possibly fitted to a JCB 3CX Backhoe Loader, can fill approximately 2,000 sandbags per hour, but with only three people.

The Mammut Turbo Packer TP150 is an electrical-powered hopper design that can be used to fill approximately 3,000 sandbags per hour with six personnel.

Other machines are available.

Sandbags can provide good protection, approximately 450 mm for fragments and 750 mm for protection against small arms, assuming sand is used, and the sandbags are compacted.

A bundle of 200 sandbags weighs approximately 38 kg, and each holds approximately 14 kg of sand.

Although double the price (about a Pound each), hessian sandbags are preferred for miliary use over woven polypropylene.

Continuous tubular sandbags will generally require mechanical assistance, but build rates can be impressive.

The equipment in the video below can complete 100m of barrier in less than three minutes.

The system can be adapted to use aggregates instead of sand.

Degrading them by fire might be easier than with single sandbags.

Personnel requirements are minimised by this technique, but it is not suitable for all applications.

Some use bitumen or cement slurries to stabilise traditional hessian/jute sandbags, although this creates a brittle surface that quickly degrades.

Concrete Canvas overlay is a proven and much better alternative, although again, not as widely used.

Sandbags have a fairly long history, and remain a flexible and effective means of creating temporary barriers and means of protection. Whilst hessian may have given way to woven plastics in some cases, and filling with a shovel increasingly replaced with machines, they are not going away anytime soon.

Gabions

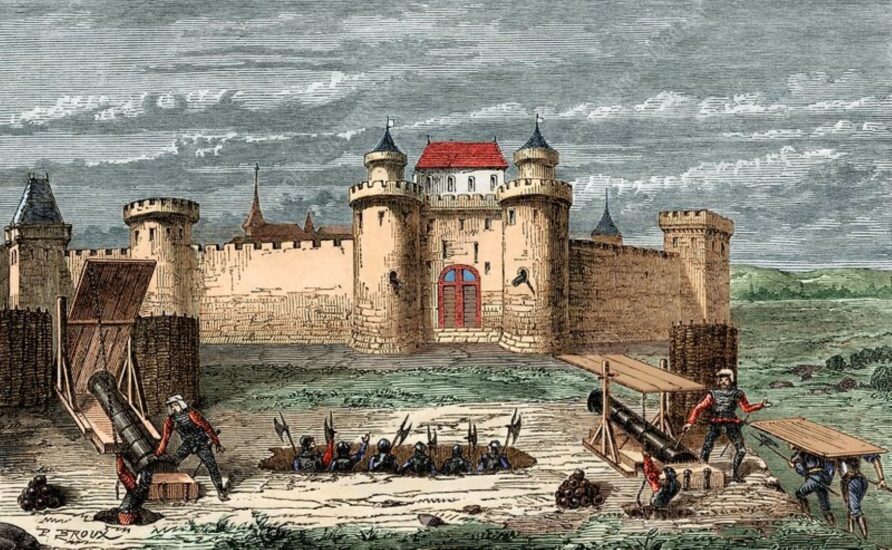

Gabions go back even further than sandbags.

The term gabion comes from the Italian word gabbione meaning ‘big cage’, it is a cage filled with rocks or soil to provide protection against enemy fire or in civil engineering.

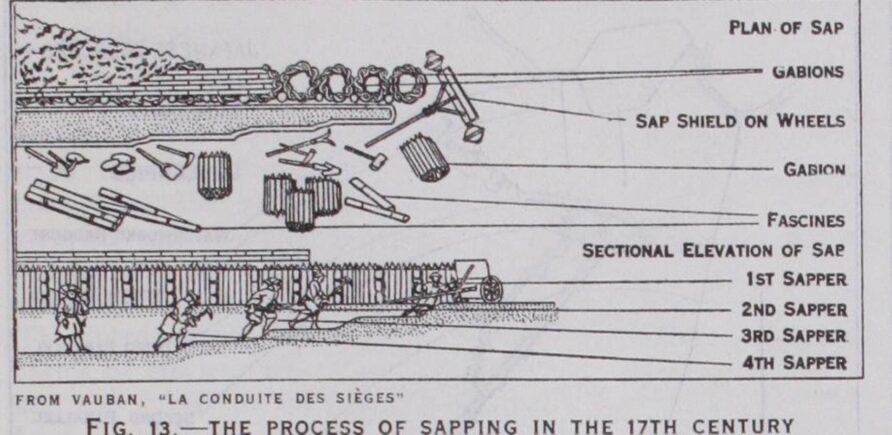

In the medieval era, they were used to protect sappers as they advanced towards an enemy castle in their saps (or trenches) but started to be more commonly used with the advent of gunpowder.

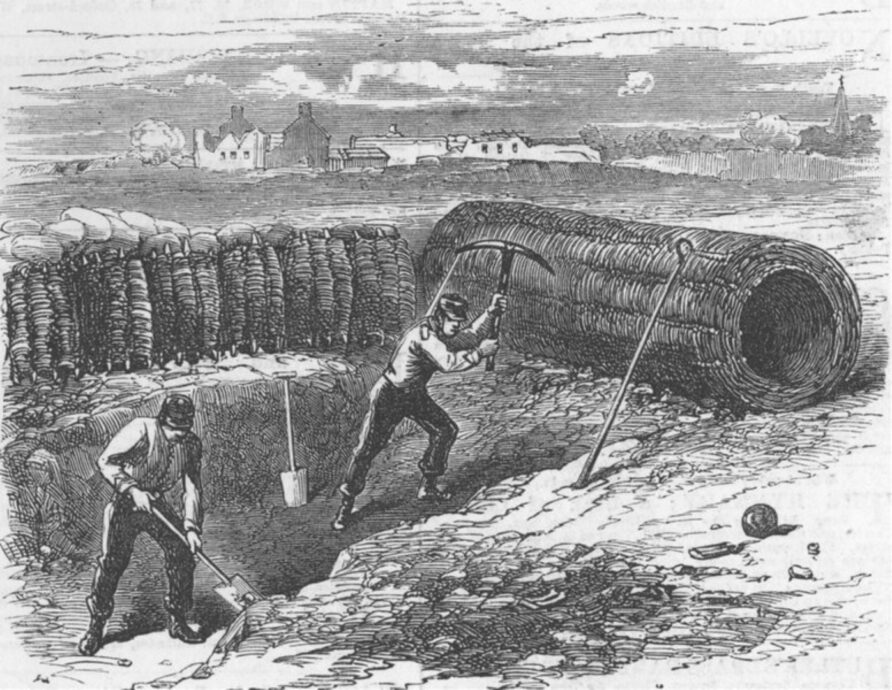

As can be seen in this image, gabions were used at the front edge of the sap, usually behind the sap shield. As the sap progressed towards the enemy, the gabions were moved forward and replaced with sturdier protection.

Gabions continued to be used for both the offence and defence, typically manufactured locally using readily available materials and filled in situ. A novel use emerged in the 1850s, the Sap Roller, a large cylindrical gabion on its side

These would be rolled forward as works progressed

Wherever there was a need for temporary protection against enemy fire, gabions would be used. Where more permanent defences were needed, timber, stone, and earth were used instead

Gabions were also used as fortification repair method.

Gabions were therefore mostly used as an expedient, where time or materials were limited.

The modern gabion (as we know it) was invented by the Italian company, Ditta Maccaferri Raffaele, Officina de Fabbro, in 1894.

Where weapons became more effective, manoeuvre more practised, and concrete and steel more available, they faded from common military use, although their use in civil engineering continued.

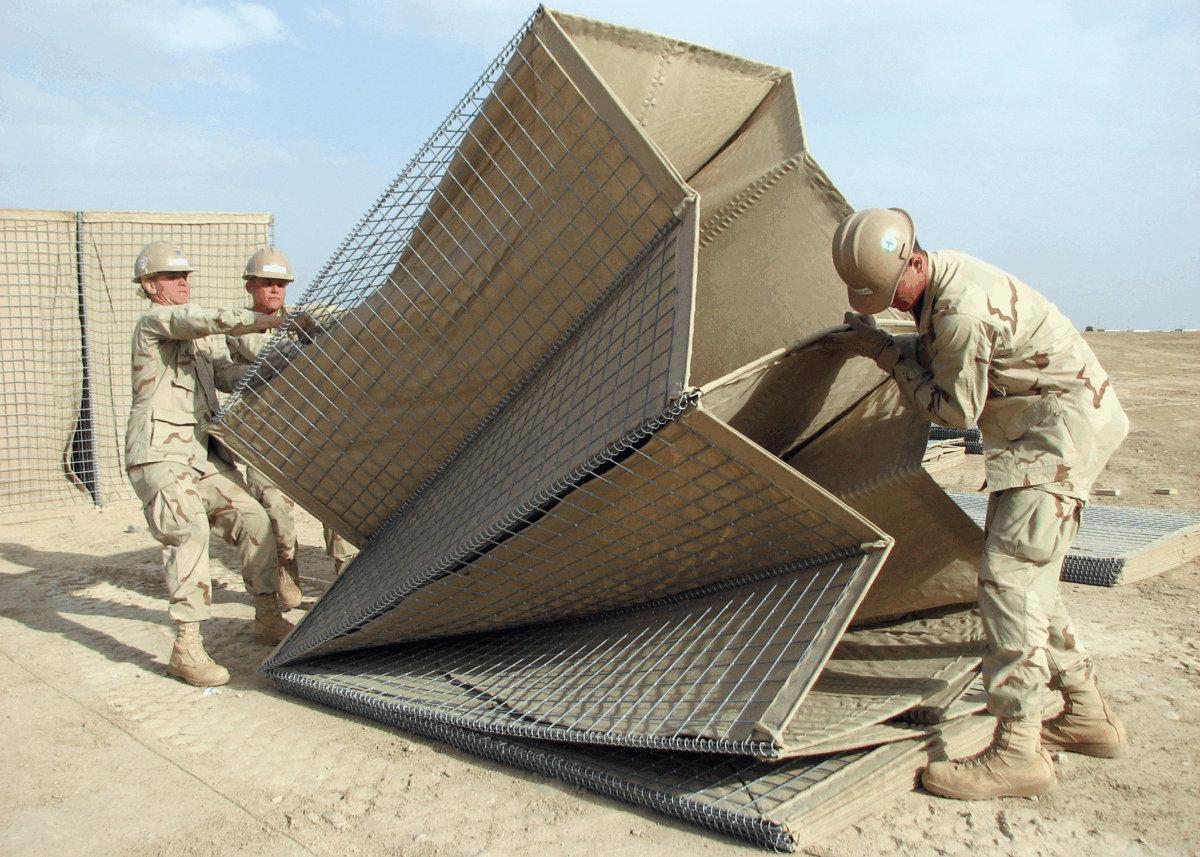

In the late eighties, Jimi Heselden, founded Hesco Bastion, creating the product we know today, key (and unique) was the textile inner and folding wire mesh structure that allowed high levels of packing density.

These were tested by the Military Engineering Experimental Establishment (MEXE)

I believe the man in the blue coveralls is Mr Heselden.

Hesco Bastion became a huge success story, synonymous with operations in Iraq and Afghanistan.

Different sized units can be used for walls, barriers, and as a shelter component.

Bastion would be used for all manner of defence infrastructure.

And, of course, furniture.

They are resistant to damage.

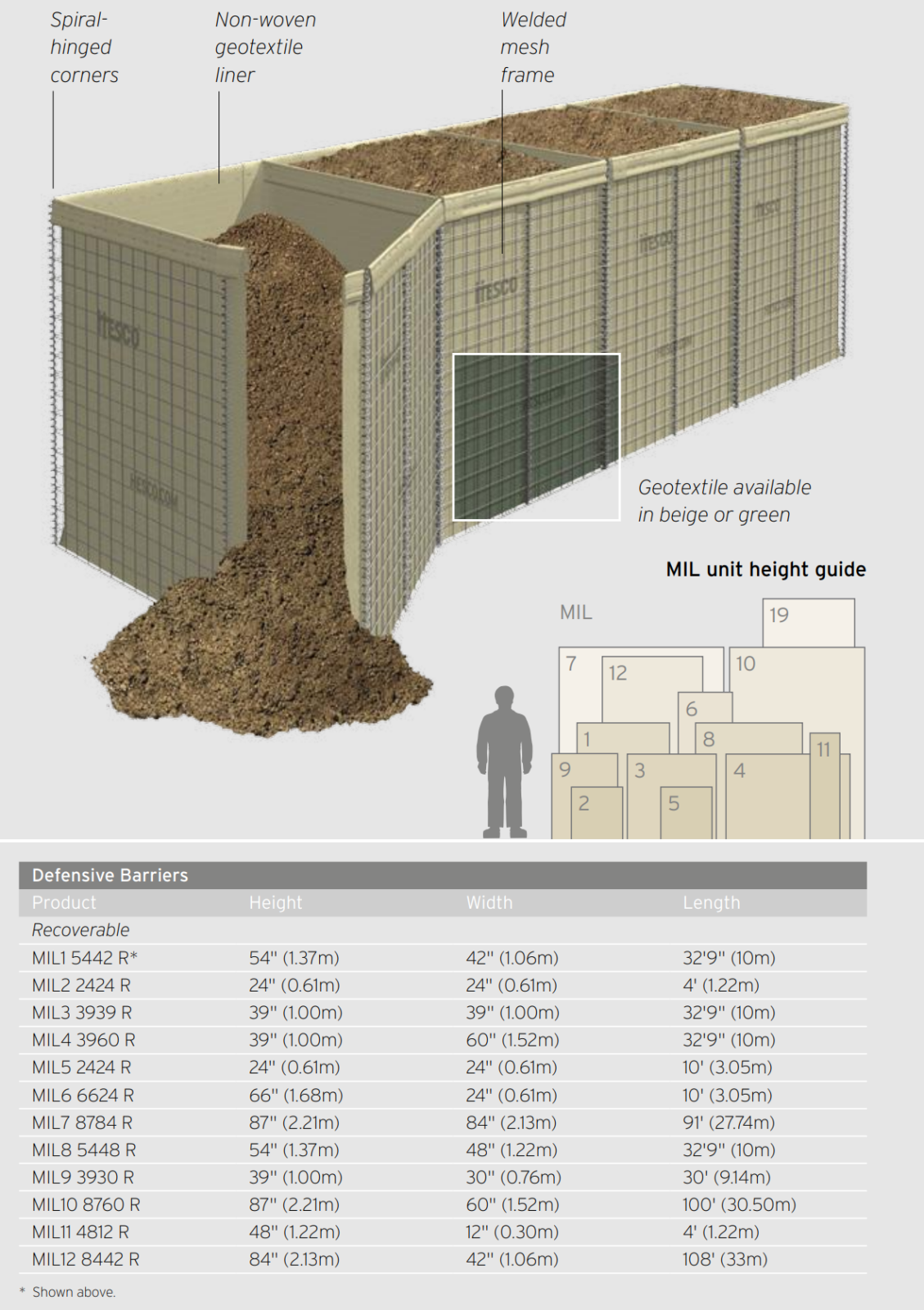

Today, Hesco markets two versions of the MIL container, in twelve size variations, the original

And a recoverable version.

Hesco Rapid in-theatre Deployment (RAID) is designed to provide a quick deploy solution for single barrier requirements.

Pretty clever if you ask me, over 300m of Mil 7 units deployed in less than ten minutes, although filling might take a while longer!

This market has changed recently, Defencell MAC is now (I think) owned by Maccafferi, HESCO now owned by Praesidiad, Dirickk engaged in legal action with Hesco, and Chinese manufacturers copying everyone.

Defencell still seems to be owned by JS Franklin. No doubt this will be out of date after publishing.

Which brings me on to…

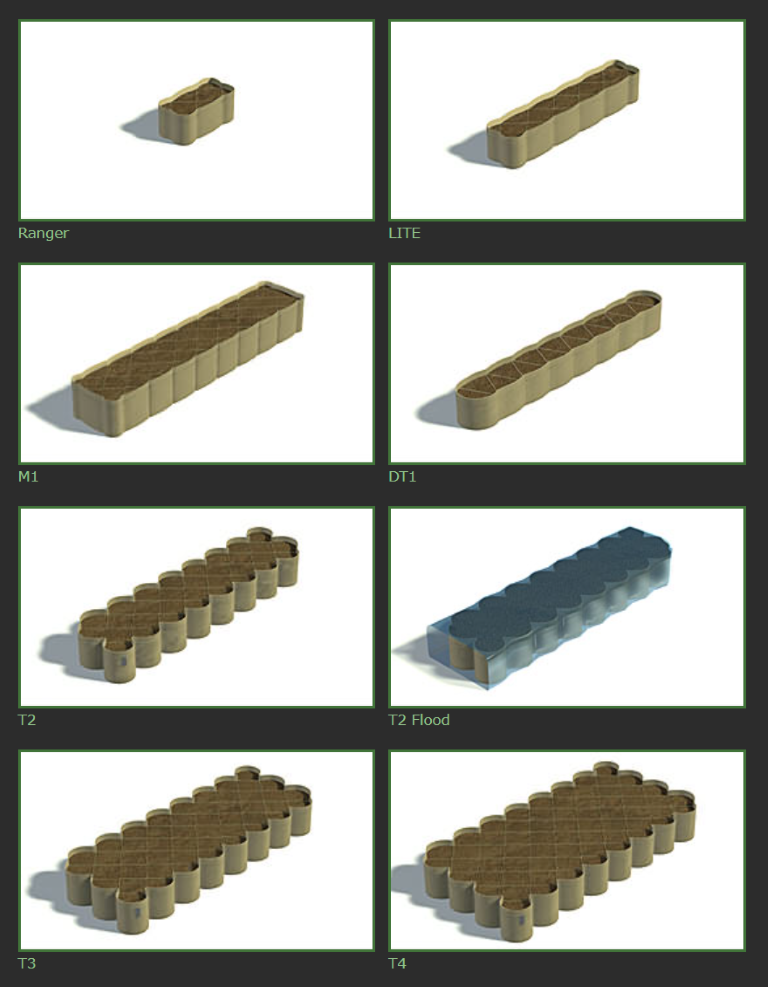

Defencell is from JS Franklin that uses a Terram non-woven geotextile self-supporting container that can be used like sandbags, gabions or to reinforce earth berms.

No metal content and high packing density are key features.

From the marketing page.

The DefenCell Barrier System allows force protection barriers to be deployed and built rapidly in operational conditions. The advanced design allows vertical walls to be built, and the modular design simplifies the construction of corners or joins and the incorporation of gates, guard posts, sentry towers or firing positions.

Successive layers of DefenCell are built to the desired height and walls of any thickness or length constructed to suit ballistic and vehicle impact requirements. A wide range of locally available fill materials can be used, including wind blown sand, and these are easily compacted to give DefenCell structural strength and integrity.

The complete range of DefenCell is made from strong, durable and internationally proven geotextile material; is lightweight, non-metallic, man portable and compact.

The system offers significant logistical advantages and a single 40′ container will provide well over 1 km of wall, 2m wide and 2m high, or 2.5 km of 1.25m wide, 1.50m high.

Compared to sandbags and Hesco type containers, they are very transport efficient and require less skill.

The Defencell M1 weighs less than 10 kg but can be used to form a barrier that is equivalent to over 300 sandbags.

The LITE (Lightweight Individual Tactical Emplacement) uses a single compartmentalised unit that, when filled, makes a wall section 3.2 m long, 0.6 m high and 0.7 m wide, equivalent to about 100 sandbags.

Here is an example of the LITE in use.

Perhaps the marketing team from JS Franklin might like to contact the MoD and correct the official image caption!

Individual cells can be stacked three high if required, and the complete unit can be carried inside a sandbag.

Each LITE weighs 3.6 kg.

840m worth of three high LITE can be carried inside a single 20 ft ISO container, or 42 m on a pallet, again, three high.

A smaller version, called the RANGER, is also available.

Empty oil drums can be used as improvised gabions, although they are generally less common now.

Somewhere between a gabion and a sandbag, the RAF has a specifically certified Single Use Lift Bag (SULB).

Available in sand, olive drab, snow, and red, they are similar to the commonly used polypropylene bulk bags used for building materials.

They have been used for flood defences and other situations where emplacement by Chinook is the only practical alternative.

The ubiquitous 1 tonne builder’s bag can also be very useful as a quick blocking approach.

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Nice to see a picture of properly laid sandbags by Sgt K. It's always mystifies me the amount of defences you see where soldiers don't know how to carry out this simple but essential task.