Battle trenches and fighting positions for small groups of individual soldiers, crew served weapons, or vehicles, are intended to provide shelter, concealment, and protection from enemy fire.

Sometimes in isolation, other times as part of a network of connected positions across a wide area.

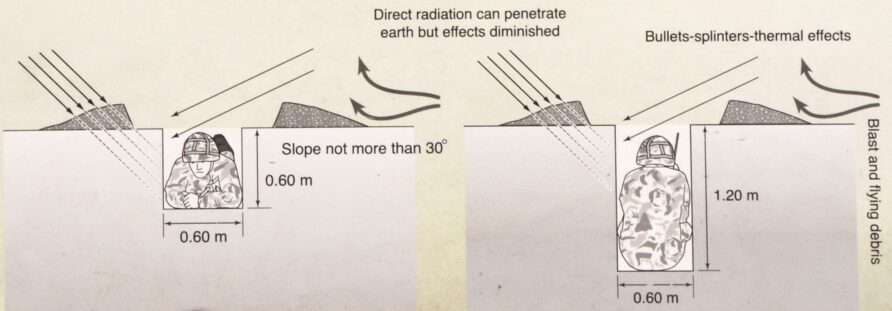

The most simple form of protection is a hole in the ground.

Moving up the utility ladder, the definition of a Battle Trench is

A tactical defensive trench that provides protection but allows observation and efficient use of weapon systems. Providing protection, which in turn, enables you to survive and continue fighting

The Battle Trench uses a simple set of components to create different designs.

One of the defining features of these battle trenches is that they are built in stages, and if necessary, using hand tools and grit!

Communication trenches may be dug to enable protected movement space between fighting positions using similar techniques, as part of a larger network of defences.

There is an argument advanced by some that given the proliferation of surveillance systems, precision munitions, and armed drones, effort spent on digging and building fighting positions is wasted.

I can see that to some extent, but I think it is too absolute, and in the most drone dense battle spaces in Ukraine, both sides are still digging.

Contemporary Designs

Two and Four Person Battle Trench

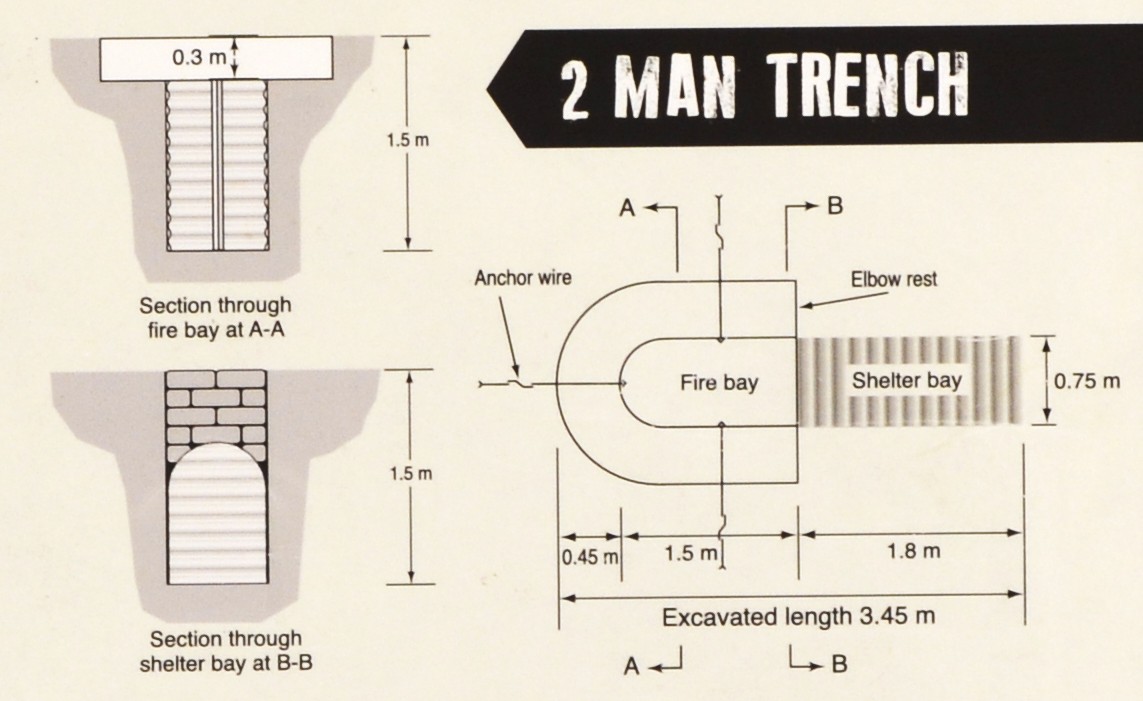

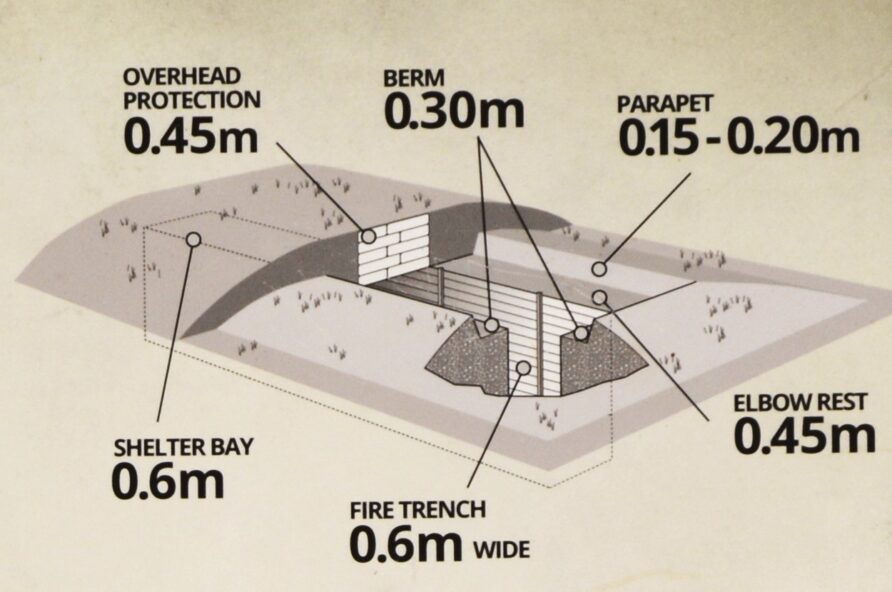

The two-person battle trench is designed to have a fire bay and a shelter bay.

Materials are simple, and probably recognisable by the oldest of the old and bold; 1.8m angle iron pickets (called Revetment Picket), 0.6m angle iron pickets (called an Anchor Picket), Split Hairpin Shelter (SHS) sheets, sandbags, 14 gauge wire, and two different sizes of Corrugated Galvanised Iron (CGI) sheets, 1.8m × 1.2m, and 1.8m × 0.6m.

Dimensions are as in the diagram below.

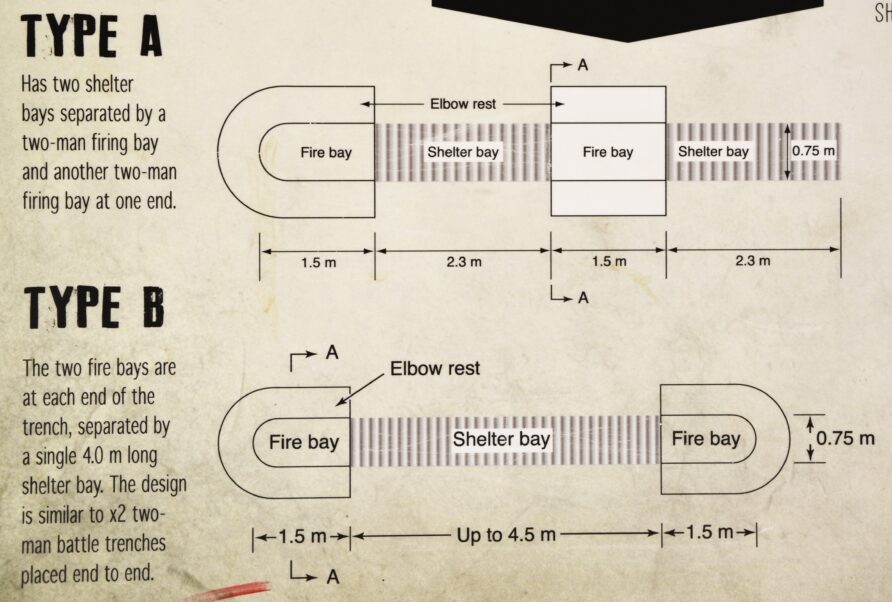

The four-person battle trench develops the basic design, providing an additional fire bay and larger shelter bays.

This is a good image that shows a Type B 4-person battle trench under construction, with SHS forming both revetment in the fire bay, and the support in the shelter bay.

Sandbags are used as an elbow rest and to stabilise the soil, and as a retaining wall for soil as overhead protection above the shelter bay.

The image below also shows the windlassed wire and pickets used to secure the revetment pickets.

Where applicable, turf is replaced, with final touches like wrapping the picket tops and using sandbags on the shelter bay entrance.

When completed, it presents very little (or no) profile to the enemy.

For both, the trench is approximately 750 mm wide, 1,500 mm deep, and the shelter bay constructed to have 450 mm of over heady cover.

Timber can be used to replace the angle iron pickets, specified as a minimum diameter of 75 mm.

This article describes a Dutch innovation for a 2-man battle trench, with a video describing the system below.

Weapon Shelters

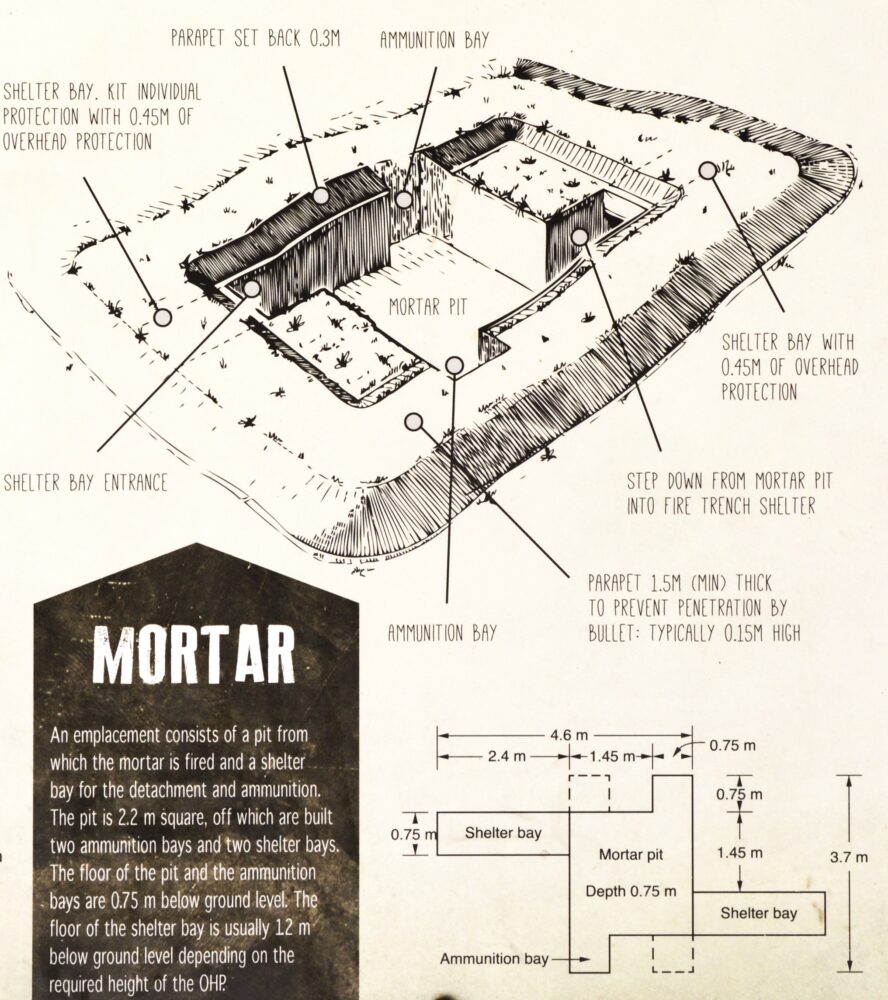

Mortars, automatic weapons, and ATGW’s tend to have specific designs that accommodate their unique characteristics.

A mortar pit.

Under construction

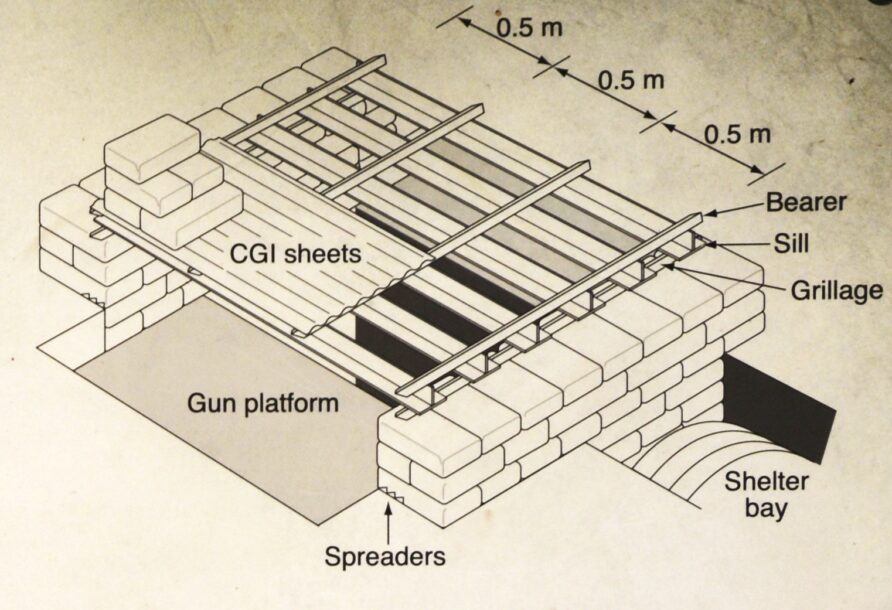

This, a fire position for GPMG.

Its construction is similar to the battle trench and mortar pit, but the roof CGI is supported by a grillage placed on sandbags and pickets.

The image below shows the trials for the British Army’s Milan replacement, MR TRIGAT, eventually won by Javelin.

The ‘Chatham Arch’ provided overhead cover for the Milan firing post and crew. The open rear provided for efflux management and overhead cover was a combination of CGI, sandbags, and in some cases, geomembrane cells.

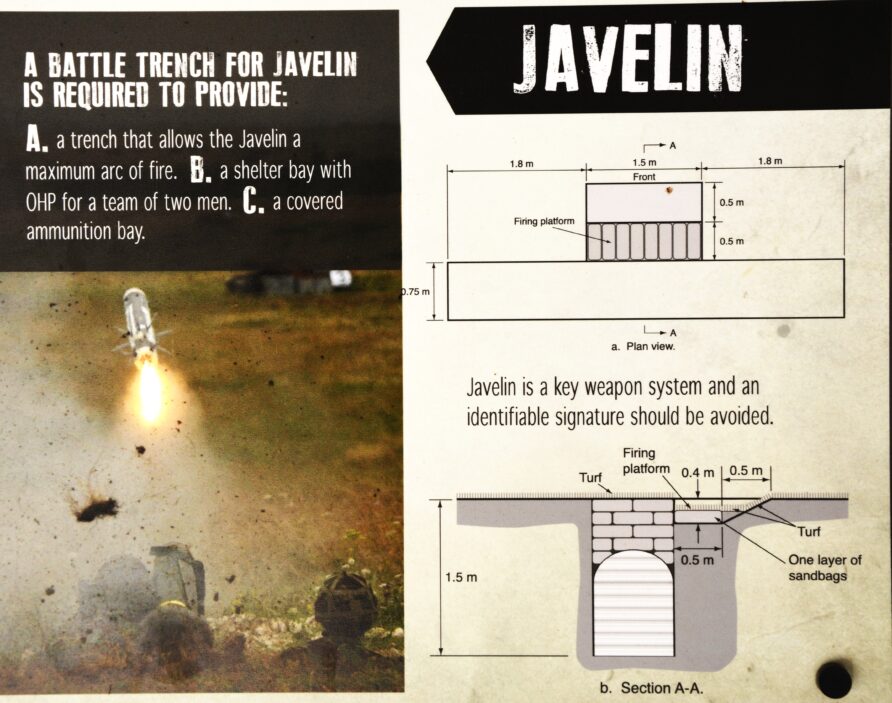

Like mortars and GPMG, the Javelin has a specific design, differing from the Chatham Arch in having no top cover for the firing platform (given Javelin is fire and forget and Milan wasn’t, I assume)

Traditional Construction

The British Army still keeps its hand in with non-standard battle trench and fighting position construction.

The example below is by 8 Engineer Brigade

Vehicle Protective Slots

These are characterised by vehicle and type

Type A is just the slot, B is with spoil removed

and C, with a parapet.

A parapet of loose soil provides a little additional protection.

Additional revetting, spaces for ammunition, and crew shelters can be added if required.

Overhead protection is not generally provided beyond cam nets, although I suspect this will change in the future as lessons from Ukraine are absorbed.

Future Threats and Issues

Wriggly tin, pickets, and sandbags would be recognised by almost any soldier from the last several decades.

There is obvious merit in not fixing what isn’t broken, but the technology landscape has changed so much recently, it would be foolish not to review.

Detection

Thermal detection equipment is increasingly prevalent. Quality varies, as does cost, but there is no denying there is much more of it about.

Multispectral sensors and Synthetic Aperture Radar can make battle trenches and other fighting positions much easier to detect than before.

Uncrewed Aerial Systems (UAS) and armed First Person Video (FPV) Drones

Detection is also joined by the threat of them carrying explosive or incendiary payloads.

I am sure we have all seen the video from Ukraine of explosive carrying FPVs being flown into dugouts, ‘thermite’ dispensing, and even UAS being used to drop grenades into the tiniest of gaps.

Excellent analysis here

Uncrewed Ground Vehicles (UGV)

Less common than UAS and FPV, but both Russia and Ukraine have deployed armed one way UGV’s, usually a means of destroying fortifications.

Fibre optic cable control systems are also now on UGVs.

The famous British robot dogs in Ukraine would be another example, able to move forward and locate enemy field defences that can be attacked at a later point.

Urbanisation

Urban terrain does not necessarily mean the middle of a modern city (that we might seek to avoid), but the increasing urbanisation of almost every part of the planet means that field defences have to evolve.

One cannot simply excavate in urban areas, there may be utilities such as gas pipes and power lines that would create a bad day for T Atkins if he took a pickaxe to them.

Fighting positions inside buildings should also be subject to study and evolution.

Cost and Logistics

Traditional battle trench equipment is transport inefficient and heavy.

SHS, CGI and pickets are not particularly easy to palletise

A Modern Battle Trench System for Modern Conflict

We will never be able to make a battle trench invisible, but there may be options to make it less detectable, to reduce the chance of being targeted.

If detected, there are also options to make any subsequent attack less effective.

DSTL ran a research project called Take Cover! in 2020/22 that looked at ideas for a future battle trench, noting that due to equipment carried, width should be increased by 25%.

The scope is worth noting.

The competition focuses on novel materials, designs and deployment technologies for field fortifications that are easily stored, transported and rapidly deployed.

Deployed fortifications should protect from ballistic threats, blast/fragmentation and ground shock, however, protection against directed energy threats is also of interest. Directed energy can include rocket propelled grenades (RPGs), high-energy lasers or other novel weapons.

Observability (in multiple environments) across the optical, infra-red (IR), ultra-violet (UV) and radio-frequency (RF) spectra will need to be considered, especially for future phases. However whilst this is not a call for camouflage technologies as such, innovative camouflage, concealment and deception (CCD) proposals that could form part of an overall solution are welcomed. The solution may also be utilised for discreet protection of cached equipment.

Whilst chemical, biological, radiation and nuclear (CBRN) threats are not the focus of this competition, it is worth noting that in an operational situation, the solution may be deployed in a CBRN environment.

After the initial stages, it progressed to two demonstrations.

Working in conjunction with DASA and two non-traditional defence suppliers, Beardsell and Sons and QUICKBLOCK, DSTL is developing deployable infrastructure using innovative new materials and techniques.

A 4-person soldier battle trench consisting of a modular box frame and geotextile faces, and a rapid vehicle check point utilising modular, foldable building blocks, have been developed and successfully demonstrated. User trials presented a major learning opportunity for the two suppliers with troops from Royal Engineers Trials and Development Unit deploying, operating from and then recovering the structures before providing feedback.

Blast trials were undertaken to understand the performance of the two structures against representative threats, including 155 mm artillery shell. The systems are being refined based on user feedback ahead of progressing to a technology demonstrator programme

But it wasn’t the first time that we have looked at improvements to basic designs.

MEXE looked at several concepts over the years.

As a replacement for CGI and pickets when used for flat overhead cover, mostly for GPMG fire trenches, a steel pole and canvas bundle.

Supported in sandbags.

With additional overhead cover provided by sandbags.

These were tested with some hefty explosions nearby.

A variation used an open weave of flat webbing.

A Sheldon Strut was tested (visible in the image below, just above the SHS in the sandbagged area)

This was used to tension additional pickets across the long span of the fire trench

The results were impressive, and designed to stop this happening.

Square tube fabrications.

And a pre-fabricated fire bay, adapted from a carriageway box used by the GPO.

They also looked at a product to improve transportability of SHS.

Using a forming frame called a camel (thanks @MickBourne1).

Normal flat CGI could be bent into a type of SHS (without the split) in forward locations, with considerable effort.

But none of these entered service

Beardsell and Sons Universal Battle Trench (UBT)

Williams Composites were one of the responders to Take Cover!

But the one selected to go forward was from a small company called Beardsell and Sons, and I think they came up with an utterly brilliant concept.

First, it comes on a single pallet, compare that with the pickets, CGI and SHI images above.

And can be easily stored.

The system can be stacked in storage with an indefinite shelf life. It is ideal for pre-positioning and rapid dispersal in support of a defensive battle plan to provide hardened fighting positions.

The basic system is for a single fire bay and shelter bay.

The system is logistically simple. 1 pallet = 1 UBT – 8 linear meters of supported trench 1m wide, comprising 4m open fire bay and 4 meters of overhead cover, parapet reinforcement and suspended flooring. The support is installed in 1m structurally independent sections and can be installed in a pre-excavated hole or incrementally as dug by hand. Offering immediate protection.

The basic frame can be extended.

With revetment and overhead support provided by geotextiles, and a suspended floor to keep soldiers’ feet out of the wet and reduce slipping.

I don’t think this has progressed to production yet, sadly.

UBT Alternatives

The Germany company Romold has looked at this problem, and created a trench system based on their utility chamber designs.

The system is modular, and reusable, with low combustible plastic components clicked together without tools.

It is palletised, with Romold indicating that a single 20 ft ISO container would be needed for 40m of trench system, and weighs 88 kg per linear metre, considerably more than the UBL.

Although noted, this is initial development rather than the finished article.

A telescopic frame and different materials are being incorporated into the evolving design.

In the UK, Cubis Systems are an equivalent of Romold

Although no specifically aimed at battle trenches, their Stakkabox Ultima system has great potential.

Large enclosures can be constructed with the system.

Or small

It has various roof/cover options, even hinged ones.

The Royal Engineers have looked at conventional trench shoring systems as well

MFG is a British company that has an extensive product range and vast experience to address some of these challenges.

I especially like their Manhole Box for larger fighting positions where engineer plant support is available.

Ukraine Experience

It is also worth looking at what Ukraine is doing.

This image from the Ukrainian Military Center Public Organization shows how they are evolving build techniques.

Making use of rough sawn timber and steel mesh, with geotextiles, to create large revetment panels.

Timber is readily available and economical, but the increase in size and material use reflects operational experience.

During the Second World War, the depth, and width of the trenches were 1.5 meters by 80 centimetres, but now we make them 2 meters deep and about 1 meter wide. And another half-meter parapet is poured on top. At the same time, we cannot make it wider because the trenches will become more vulnerable to shelling. We use geotextiles, mesh, boards, and timbers in the construction

These are not specifically fighting positions, but for moving between them, the additional size eases movement of stored and wounded personnel.

Another observed method is to use steel trestles and roofing sheets, together with a similar approach to revetment above.

Welded in place, these produce strong systems.

When time allows, these communication trenches are braced at the top and covered to prevent observation and some protection against UAS/FPV type drones.

In many of the different images of Ukraine trench systems I have seen, this method of revetment seems the most common.

Other Materials

Some other materials might be useful to investigate, I like the Ukrainian system for revetment panels, making use of weld mesh and geotextiles.

This is very economical, a 2.4m × 1.2m of 75 mm galvanised mesh only costs less than £40, a 100m role of 4.5m wide geotextile, less than £200.

Geogrids and geocells are equally low cost, for flooring and earth retention on areas of overhead cover.

As per the MEXE Shelter post, Unistrut is also a flexible and low-cost means of building strong frames and roof structures.

A roof structure could also use commonly available road plates, such as these from Oxford Plastics.

Trench safety covers, when combined with a geotextile, might also provide another combination for overhead cover.

This, from Oxford Safety Components, is a good example of what a modern IPK could look like.

Layout, FPV and UGV Protection

Numerous videos from Ukraine show the devastating impact of armed FPV UAS dropped explosives on trenches, dugouts, and other enclosed spaces.

With nowhere for the blast to vent, the occupants bear the full brunt.

Layout

All the current designs are laid out in a single line with no offset.

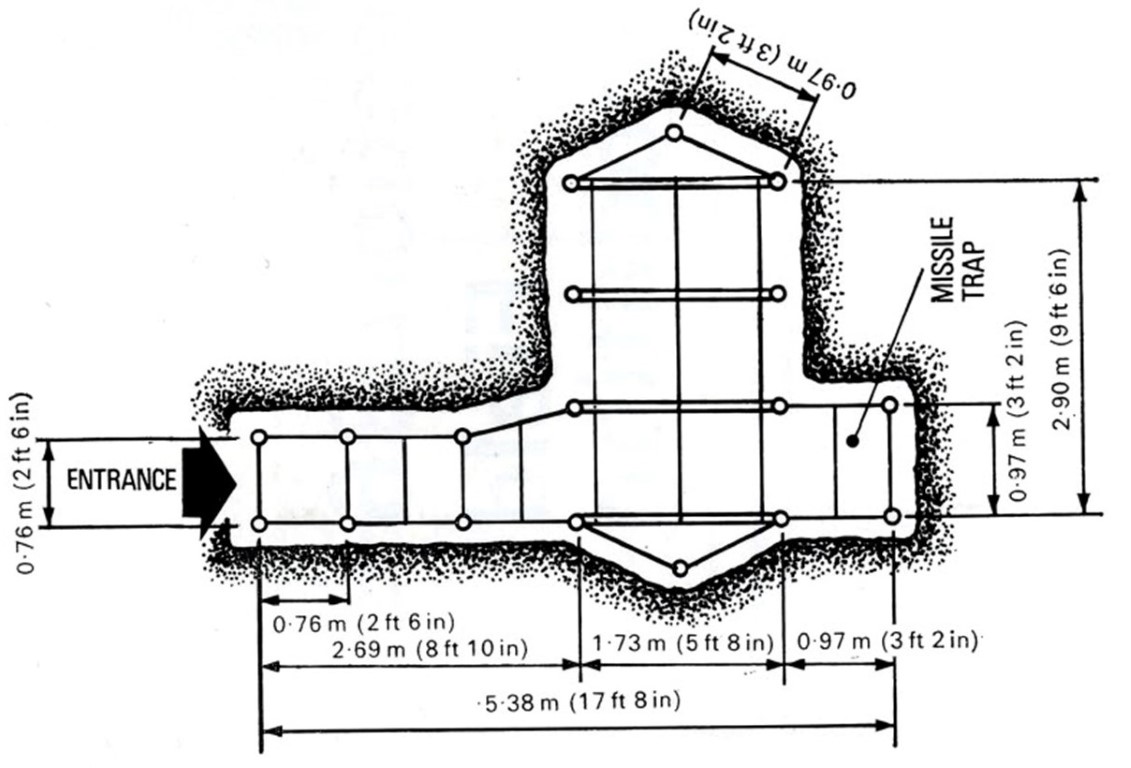

Cast your mind back to the MEXE Shelter post and the discussion on the ‘missile trap’. Not a missile as in ATGW, but fragmentation and debris from an external explosion.

An alternative layout for a battle trench could see it being a T or L shape, with the shelter bay at an angle from the fire bay.

These might not be ideal as it would present the entrance to the shelter bay directly in line with the enemy, an oblique T position could offer a compromise.

Although it might seem a bit left field, it might also be worth looking at layouts for directing blast.

We have seen blowout panels on armoured vehicles, something similar for a battle trench would be in interesting concept.

Using a combination of layout and composite panels inside the battle trench, angled and fixed to encourage the blast from an explosion inside to vent out and up., like a chimney!

Protection

Half a metre of earth still provides excellent protection against shell fragmentation, grenades, automatic weapons, and some effects of nuclear weapons.

As we see more precision being employed, we should focus on detection avoidance, blast mitigation, and physical barriers.

Careful spoil management, turf replacement, and multispectral camouflage systems such as Saab Barracuda ULCAS or Fibrotex Sophia

In an urban environment, below ground battle trenches have generally not been considered attractive. But with overhead protection in the form of an abandoned car or road plate, we could reconsider.

Even the simplest of battle trenches could be provided with protection against UGV infiltration and attack. I will look at this subject in more detail in a later post, but even some pickets and a couple of bags of nylon tangle mesh (gill netting) could quickly provide an effective barrier.

Summary

As demonstrated by the Take Cover! DSTL work and resultant solutions from QUICKBLOCK and Beardsell & Sons Ltd (B+SL), there is still appetite and innovation out there, ready now to be further exploited.

I think both are no-brainers to be honest, and I particularly like that both consider transportability and logistics as integral to their designs.

Getting them into service allows rapid adaption and the development of new techniques and procedures, for example, different layouts or spoil management and spacing.

They could also be used with composite panels like those from NP Aerospace or FYC in Finland, building protection levels without massively degrading transportability.

Camouflage is now more than just old-fashioned cam nets, there are multispectral systems that can be purchased off the shelf.

Add in counter UGV barriers and you end up with a decent system.

That said, I do think it would also be good to look at improvised solutions as well.

Unistrut, scaffold poles, trench covers and road plates, safety barriers, geotextiles, Heras type fencing, and even pallets, all are readily available in most of the places the British Army is likely to find itself in.

We certainly have the expertise to try them out, build a library of options, and put them into an online battle-box.

All we need is a bit of cash, cars not houses cash!

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Thanks for the mention. The Universal Battle Trench is as strong as we could make it within the design brief. Front line soldiering is in for some change and the contested logistics environment that FPV drones create cannot be ignored.

The IPK used both for providing OHP, as desciribed above, and as an improvised thermal masking sheet is currenlty being taught in the survivability module at IBS Brecon. While not perfect for either role it is multi use (reducing burden on soldier) and is cruicially in the G4 chain now. An 80% solution perhaps?

Brilliant, thanks for the update G, I honestly thought they had all gone now. I guess we produced them in huge quantities. Am working on a future post that will look at a modern version

In your post Battle Trenches and Fighting Positions" you have presented the ROMOLD plastic trench system as an initial development.

Now the system is „finished“ and installed at the engineering school in Germany.

A slideshow of it is here to see:

https://youtu.be/xHyySatwj5A

The actual used British system is optimized for the direct area of contact with the infantry enemy. It is a simple, rapid entrenchment without technical support.

Such a mission is limited in time and must be carried out under simple conditions. It requires no comfort (additional: the simple corrugated metal sheet provides the soldiers only limited protection and cannot withstand any earth pressure).

The Ukraine war shows a different picture.

Fighting in and from trench systems has become much more important.

Drones are everywhere on the battlefield.

In the battle of the future, the infantryman must be almost invisible and still be able to move in order to survive (bunkers and armoured vehicles are not always available).

This is why many NATO armies have begun to rethink and start to train groups, platoons and companies in the construction of and fighting from trench systems.

We believe that an army must be able to master both mission scenarios and therefore needs two systems.

The actual British system for rapid, temporary mission without comfort, very close to the enemy.

An other system for longer missions with high protection, secure communication trenches and a comfort to maintain the fighting strength of the soldiers. This is what the ROM-Trench from ROMOLD stands for.

These two systems do not contradict each other, they complement each other.