These are not fighting positions, sangars, guard posts, or barriers

As with the previous post on buried shelters, these Above Ground Protected Shelters are used for rest areas, medical facilities, HQ and CP functions, storage, and equipment care.

Gabion Wall Shelters

Steel mesh baskets with fabric linings were a ubiquitous image from Afghanistan and Iraq, yet they go back centuries, and I will cover them in much greater detail in a separate post.

As well as barriers, they can be used as a wall construction technique for larger shelters.

This market has changed recently, Defencell MAC is now (I think) owned by Maccafferi, HESCO now owned by Praesidiad, Dirickk engaged in legal action with Hesco, and Chinese manufacturers copying everyone. Defencell still seems to be owned by JS Franklin. No doubt this will be out of date after publishing.

Wire mesh or textile gabions/baskets can be used as both structural components and to provide protection in larger shelter designs.

The Hesco Accommodation Bunker (HAB) combines their well-known basket products with a roof support system.

The plywood roof provides a pre-detonation screen.

A second generation product provides additional blast and direct fire protection, using an aluminium pre-detonation screen.

These, and their smaller products that use accommodation containers from Edilsider provide good levels of protection but require considerable fill material.

Other manufacturers market similar shelter designs.

Although Hesco is widely known, JS Franklin Defencell is much less known (their marketing isn’t strong), and less used as a larger shelter wall system, it can be done, though.

Concrete Canvas

Although stretching the definition large, a concrete canvas shelter does have the advantage of providing a measure of protection without needing extensive excavation, equipment, or time.

Concrete Canvas Shelters are rapidly deployable hardened shelters that require only water and air for construction. The construction sequence is shown below

Once inflated, it provides a Nissen hut type shelter, once hydrated, the concrete begins to cure, achieving desired strength within 24 hours.

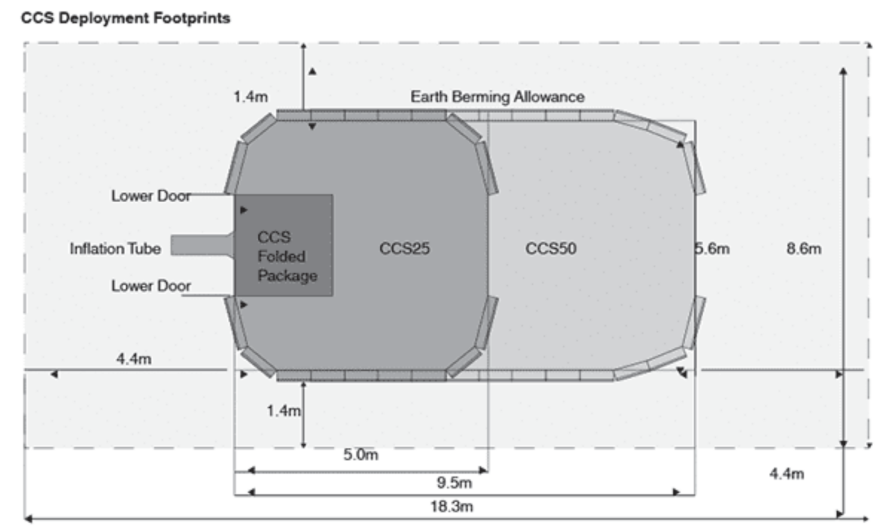

The compressive structure of CCS has been modelled to be covered with sand or earth fill. This provides additional thermal mass and insulation, and an excellent level of thermal performance. Combat Concrete Shelters have been tested to withstand a bare charge of 5 kg (similar to a shock wave of a 155 mm round) at a distance of more than 10 feet (ca. 3 m). In addition, the shelters can be bermed with earth, snow, or sand to add additional insulation and protection.

The smaller shelter can be deployed by two people, but the larger CCS50 requires some form of mechanical assistance to unfold.

Each shelter is plastic lined.

And can be linked to form larger structures.

Concrete canvas shelters can be stored until needed, are efficient and simple to use, they even provide a good level of basic protection that can be improved up with roof cover and gabions (and UAS mesh more recently)

Interlocking Concrete Blocks

Covered in more detail in the previous post on larger buried shelters, they are durable, cheap, and easy and quick to use.

Concrete/steel joists can be used to create longer roof spans.

This can provide an advantage by building protected shelters inside a normal-looking industrial or agricultural building.

Another advantage is they can be stockpiled over time and don’t degrade when stored outside, for national preparedness, they are an excellent option.

Fabric Shelters

Fabric shelters are slightly out of scope for this series of posts, all require some form of protection against enemy fire.

So none of these.

Not at the theatre level, or at the scale of ARRC, groups of tents are still used extensively.

An interesting product from Finland provides a composite protection systems for larger tents.

The FYC Fragment Protection System is a composite ballistic protection panel that can be used with a tentage.

The tent is like many others, but the protection panels make it stand out.

The RASS TENT is an advanced modular shelter that offers protection throughout the year, this is because the materials used have been developed to withstand harsh subarctic climates. The RASS TENTS are extremely suitable for armoured commander posts and protect valuable medical instrumental and also as a specially equipped more protection Ballistic and Multispectral Camouflage. The frame is made strong aluminium and designed for heavy use carrying material layers inside of the tent.

Perhaps NP Aerospace could do something with their CAMARC panels?

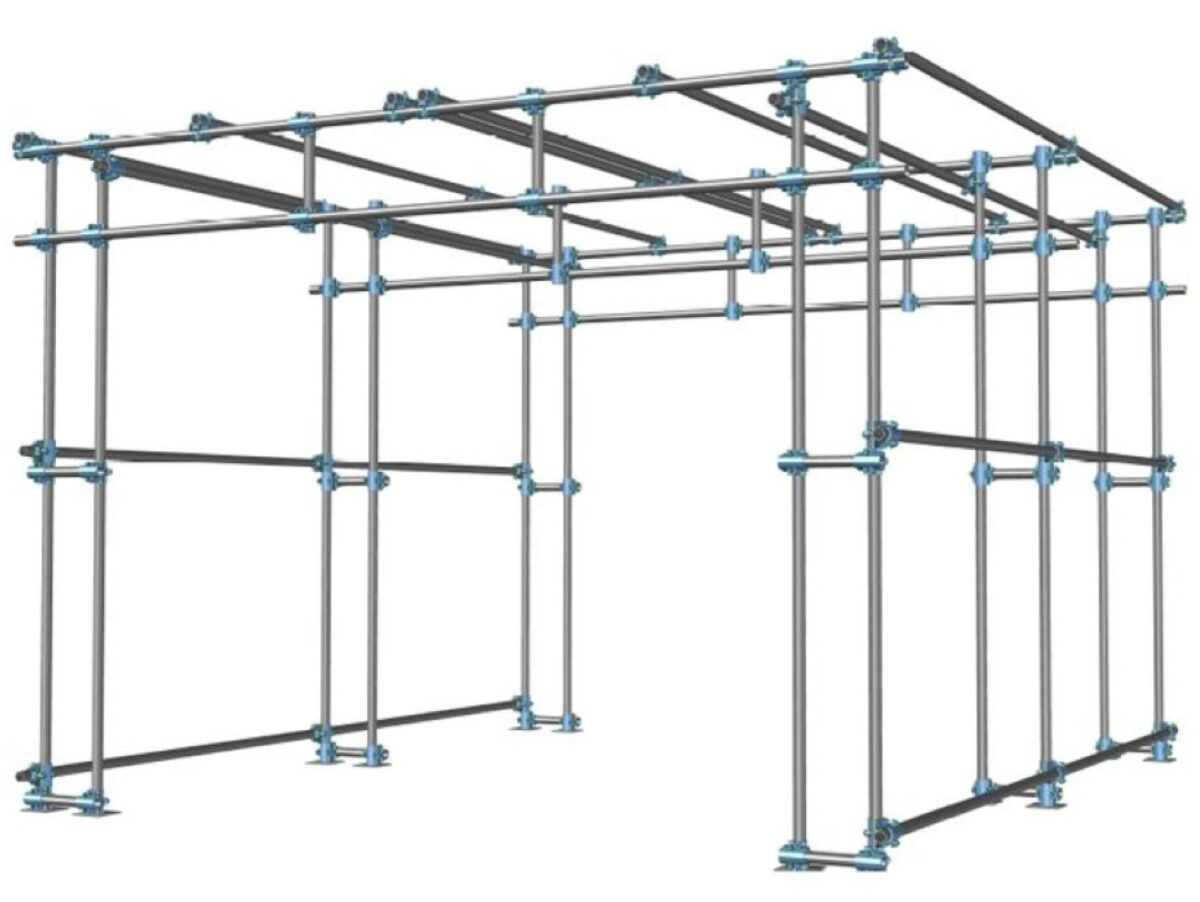

With a scaffold or other tube and clamp system used to affix the panels to.

This would be a useful alternative to concrete blocks, and easier to deploy, store and transport.

Although they provide zero protection, container/fabric shelters are still useful, especially if they blend in with the local surroundings.

With good signature management and smart siting, they can provide concealment, although not much protection.

ISO containers can be used, or filled to increase protection.

Interlocking concrete blocks can also be used.

Nixus Shelter in the UK has a version of this for defence applications (as well as some very capable shelters of different designs)

QUICKBLOCK

QUICKBLOCK is a rapid-assembly building block made from 100% recycled plastic, requiring no specialist skills, tools, or materials.

Unlike the interlocking concrete blocks, structures can be built with them don’t need any engineering plant.

They are also very space efficient in transport.

To add protection, the blocks are in filled with soil, sand, or other granular materials, and obviously, this will require transport if not readily available nearby.

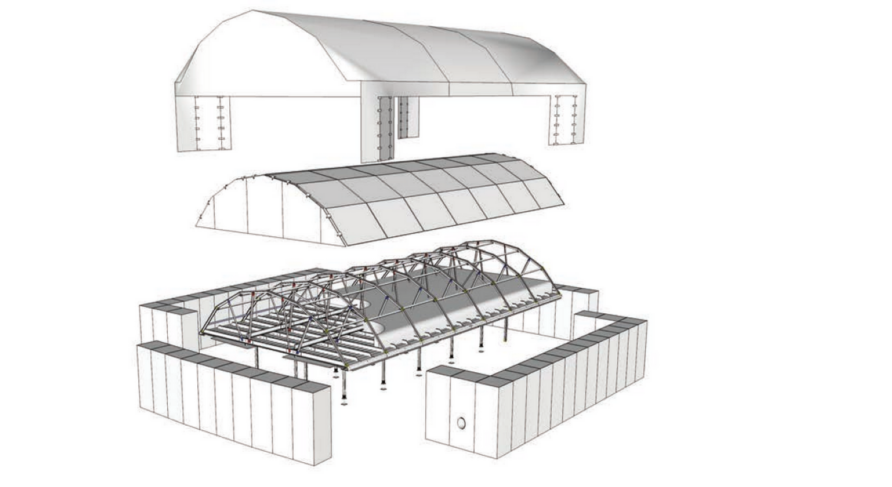

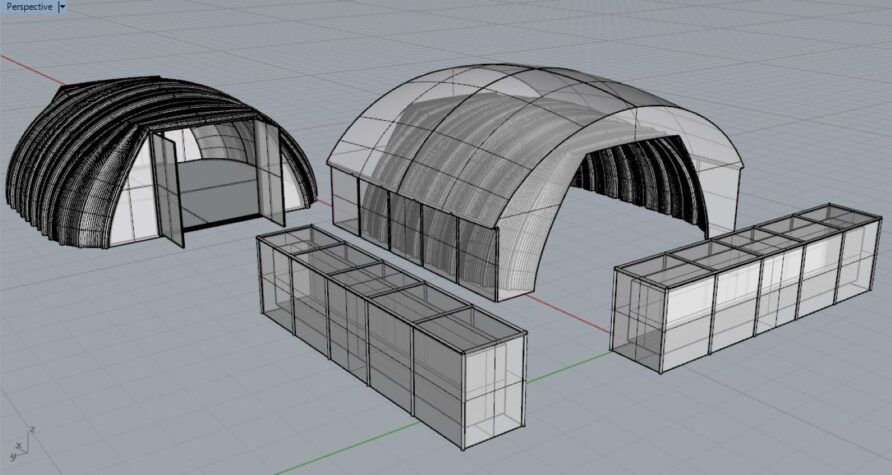

A roof structure, using round tube and connector systems, can be added

QUICKBLOCK also has a version of their product made of steel and composite material, and this provides ballistic protection without any infill.

QUICKBLOCK is an innovative UK manufacturer.

Precast Wall Sections

Back to concrete, precast retaining and dividing wall panels can be used inside.

Or outside.

They do require a lot of transport but can be quick to install where aggregate or fill material is not readily available.

They are not commonly used with roof panels or overhead cover, but any of the systems described above or in the previous posts could be adapted.

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.