The Mexeflote is a modular pontoon in service with the British and Australian armed forces and is primarily used to transfer vehicles, stores, and equipment from ship to shore.

In service since the sixties, its basic design has endured, but at some point, it will need replacing.

History of the Mexeflote

The Mexeflote came into service with the British Army in the early sixties.

One of its conceptual predecessors is the US Rhino Pontoon.

After WWII, some work was completed with the Heavy Ferry, whose development started in 1947, for ship-to-shore transfer of tracked vehicles.

The initial Heavy Ferry designs used four propulsion pontoons, one at each corner, that made use of the Hotchkiss Cone Propellor design for use in very shallow water. By the time it entered service in the early fifties, the Heavy Ferry still had four propulsion units, but they now used a Gill water jet powered by a Rolls-Royce B80 engine.

Gill water jets are still going, trading as Tees White Gill now.

Pop over to the Shiny7 website for some great images of the Heavy Ferry.

The Thos Uniflote Pontoon was another similar design, shown below, operating in Aden with a single outboard engine.

The Uniflote pontoon was found to have weak couplers in the offshore environment, so the Mr Eric Longbottom of the Military Engineering Experimental Establishment (MEXE) designed the Harbour and Landing Ship Logistics Pontoon Causeway, more commonly known as the Mexeflote.

A Royal Engineer Major during WWII, Mr Longbottom was also involved with the design of the Heavy Girder Bridge.

This 1967 video from British Pathé provides a good overview of Mexeflote in use

The US tested Mexeflote in 1970 and found that whilst the larger Navy Lighterage pontoon performed better in higher sea states, Mexeflote had much-improved flexibility and recommended it for future Landing Ship Tank (LST) designs.

Manufacturing rights were granted to Fairey Engineering Ltd in Stockport, now WFEL.

They have remained more or less unchanged and in constant service then, repaired and refurbished, new propulsion units added, but the same design concept as created by Eric!

The 1982 Falklands Conflict

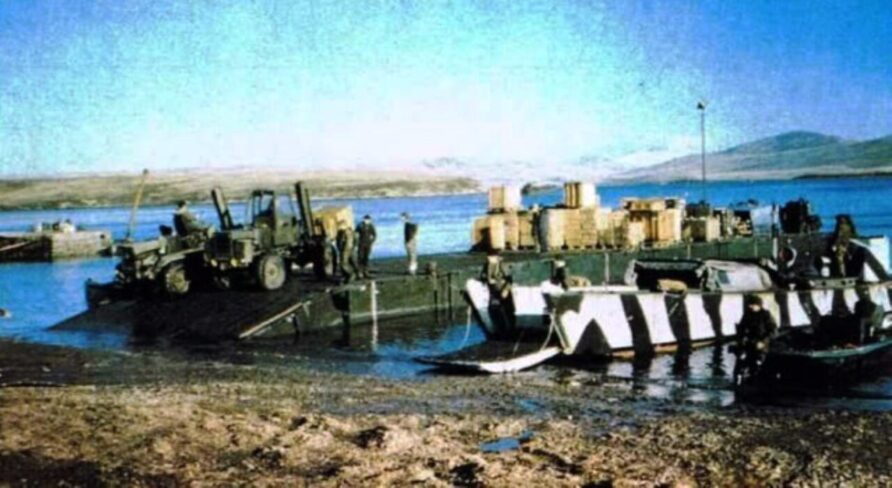

2 officers and 151 other ranks from 17 Port Regiment, Royal Corps of Transport would provide the five Mexeflote and mechanical handling capability for the Task Force.

Because of concerns about severe weather ripping the Mexeflote off their normal sideloaded locations, they were carried as deck cargo and craned overboard when needed.

At Ascension, most of the stores for the initial landings were split between the LSL’s Sir Percival and Sir Galahad.

Operation Sutton was the landings at San Carlos and within 5 hours all the personnel were ashore. 3 CDO Logistics Support Regiment set up at Ajax Bay or Red Beach and started the task of unloading the stores from the LSLs.

It was estimated that Mexeflote’s shifted over three-quarters of the stores transferred from ship to shore.

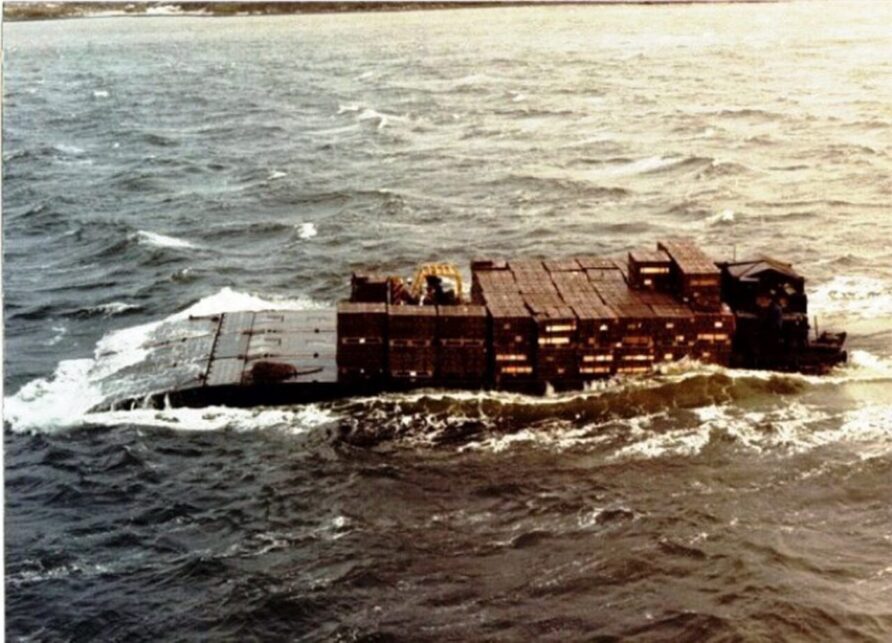

Mexeflote were used as causeways between ships in the open ocean, stores were driven between ships over a Mexeflote causeway with Fiat Allis and Eager Beaver forklifts.

In San Carlos water they were used in overload conditions, the pontoon underwater, the deck awash whilst carrying loads approaching 200 tonnes, double their rating.

The Military Medal was awarded to Sgt Boultby for using his Mexeflote to rescue survivors at Bluff Cove.

Sergeant Boultby of 17 Port Regiment, RCT, was the NCO in charge of MEXEFLOTE rafts throughout the Falkland Islands operations. At Ascension Island, during a massive re-stow operation, he worked all hours under difficult conditions to move cargo quickly. In San Carlos Water, the MEXEFLOTE rafts played a major part in the logistic landing of equipment to ensure the success of the fighting troops. From the exposed position which such a raft offers, Sergeant Boultby worked continuously throughout daylight hours and in extreme weather conditions. The vulnerability of his position to constant enemy air attack did not deter him from his task, and he was an inspiration to his crew and other RCT personnel. He was coxswain of the MEXEFLOTE present at Fitzroy during the bombing of RFA SIR GALAHAD and RFA SIR TRISTRAM, and repeatedly returned to the area of the stricken ships to rescue survivors and, with complete disregard for his safety, dived into the sea to rescue a Chinese crewman. Sergeant Boultby’s dedication to his tasks in dangerous conditions was outstanding.

Mexeflotes would also provide sterling service after the cessation of hostilities and were the only thing capable of offloading bulk materials and heavy stores until the Ramped Craft Logistics arrived.

The importance of the Mexeflotes and their 17 Port Regiment RCT operators cannot be overstated, without their efforts, the materials required to construct the facilities at the RAF Stanley would have taken an immeasurable amount of time longer than required.

With a journey time between the ship and B slipway in Port Stanley Harbour of between 30 and 40 minutes, the maximum weights would have to be exploited. AM2 and construction plant is heavy, and even the Mexeflote was seen to struggle on occasions.

Slipway B was the only useable slipway for heavy stores and had to be repaired and reinforced by the sappers before use.

One particularly challenging load was the pair of 45-tonne rock crushers required at the Mary Hill quarry near the airport, the operation had to be carried out at night because they would not fit under the overhead power and telephone wires in Port Stanley, the wires were temporarily lifted as the equipment was very slowly pushed and pulled into place by a recovery vehicle and Combat Engineer Tractor.

In one incident, a pair of Haulmatic earthmovers were lost over the side of a Mexeflote during poor weather. They were eventually recovered, repaired and rechristened as Aquamatics!

They were also used for transferring prisoners to the SS Canberra before sailing home.

2010 Haiti Earthquake Response and Beyond

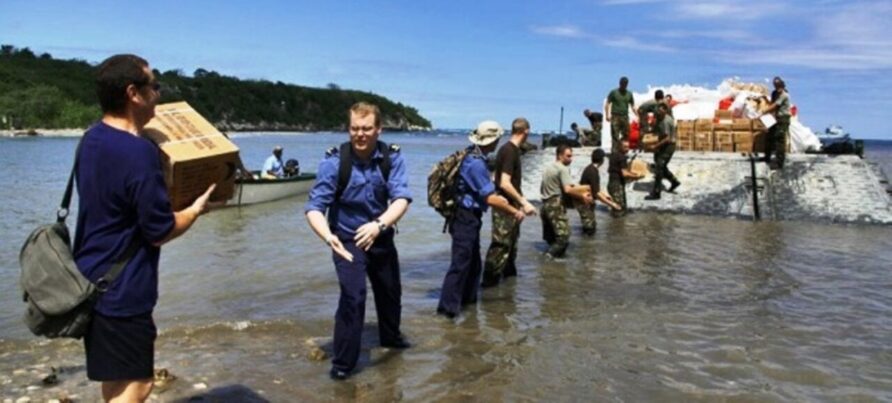

The UK’s response to the 2010 Haiti earthquake was mostly carried on the RFA Largs Bay (now HMAS Choules) and Mexeflote was used to transfer the vehicles and supplies to shore in addition to acting as a general-purpose transport capability supporting the wider operation.

17 Port and Maritime Regiment, Royal Logistic Corps, and other members of her embarked force delivered vehicles and building materials at Port-au-Prince.

After completing the initial deliveries, she was tasked by the World Food Programme (WFP) to deliver food to areas that had been cut off by the earthquake, the village of Anne-à-Veau, in Nippes province, for example.

The four-day operation at the village delivered 275,000 ready meals, 30 tonnes of rice, six tonnes of beans, more than 200 boxes of corn soya blend, 100-plus boxes of vegetable oil, and 13 bags of salt.

Since then, Mexeflotes have been regularly used in the Caribbean for disaster response, most notably in the aftermath of hurricanes such as Hurricane Irma.

The slides below provide a good overview.

https://evaintheuk.org/wp-content/uploads/2018/05/TimBrentpresentation.pdf

When on duty in the Caribbean, the RFA vessel carries an enhanced Humanitarian Aid and Disaster

Relief (HADR) Troop consisting of 30 personnel, including

specialist drivers, artisan tradesmen (2 Carpenters, an Electrician, a Plumber, and a Mechanical Fitter), Communications specialists, Plant and Vehicle mechanics and specialist boat operators. Vehicles carried include 4 Land rovers with trailers including Fit for Radio, Field Repair and Battlefield Ambulance variants), 2 Pinzgauer, 4 MAN 6-tonne support vehicles and 1 JCB Light-wheeled Tractor.

Closer to home, they have also been used for supporting civilian authority, the example below involved the rehabilitation of the Pewit Island bird sanctuary.

Australia

RFA Largs Bay was sold to the Royal Australian Navy in 2011 and renamed HMAS Choules, the sale included her Mexeflotes.

The ADF has pushed the envelope of the Mexeflote, presumably testing concepts out before their longer-term landing craft strategy is realised.

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Mexeflote Capabilities

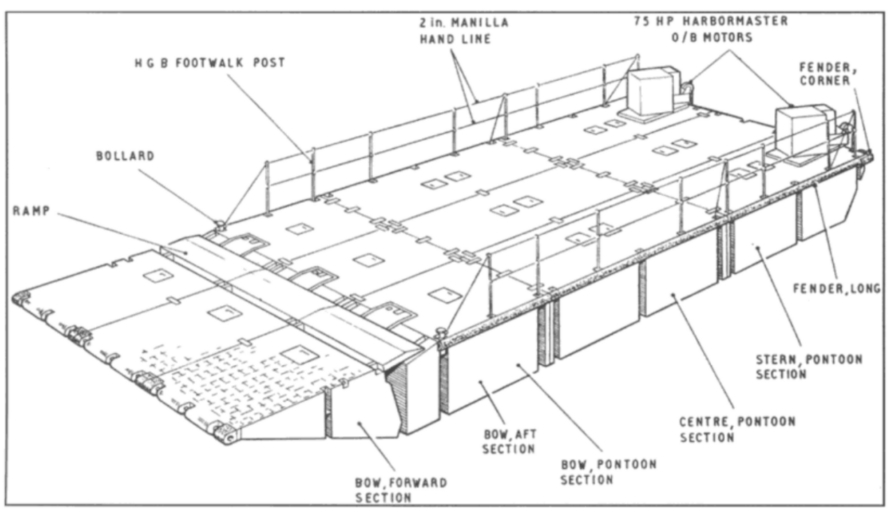

The Mexeflote comprises different sections, like Lego, and a propulsion system. The sections can be assembled into different configurations of powered and unpowered rafts, causeways, and pontoons.

Sections

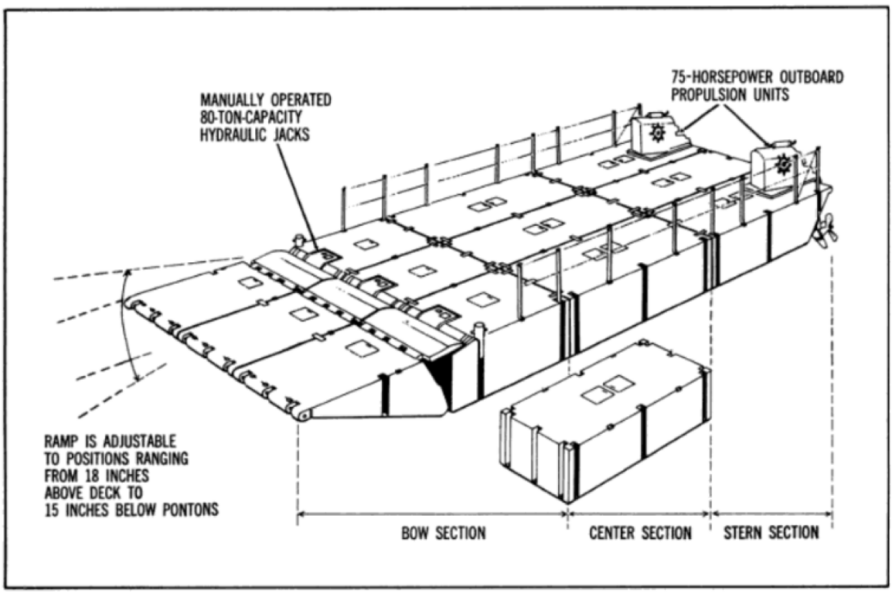

The Bow Section is 7.9m long and weighs 5,909 kg, the centre section, is 6.1m long and weighs 4,654 kg, and the stern section is 6m long and 4,418 kg.

All three sections are 2.44m wide and 1.45m deep and of welded steel construction (steel frame and cladding, forming watertight sections)

The bow has a bottom-mounted hinge designed to accommodate different beach or ramp angles, the stern section can be fitted with propulsion units.

The bow consists of a forward section, an aft section and a ramp.

The forward section is hinged to the bottom edge of the box-shaped aft section and can articulate vertically to a maximum of 457 mm above the deck level and be lowered to a maximum of 380 mm below the surface of the aft section. The manually operated, demountable articulator is mounted in a recess in the aft section and is connected to the forward section by an articulator ram.

The articulator has a safe working load of over 80 tonnes.

The pontoon ramp is hinged to the forward section and slides over the forward end of the aft section to bridge the gap between the sections.

The centre pontoon is a box-shaped unit with an internal lateral bulkhead dividing the interior into two watertight compartments.

The stern section has a slightly different design than the centre and can be fitted with propulsion units and operator facilities.

Built into the sides and ends of the pontoons are recessed slots into which the connectors are fitted.

Propulsion

The image below shows the original Harbormaster outboard engines.

These were subsequently replaced with larger units.

Henry Sykes plc were awarded a £1.4m contract in 1985 for 67 of their 75hp Hydromaster propulsion units for use with Mexeflote. In 1994, the Army ordered an additional 50 units and in 2000 upgraded many of them.

Some older units were replaced with OD150Ns from Thrustmaster in Texas.

And when installed

In addition, the propulsion units, the crew of six operators also have a demountable shelter.

A new set of Hydromaster Series 3 Outboard Propulsion Systems were obtained in 2020, each with a 150hp Cummins engine.

These were obtained under a 7-year maintenance £26.7m contract with Barrus, let in 2020 to include

The contract covers support to approximately 1100 boats within the current MoD in-service fleet for craft under 25 metres, including Inflatables and Rigid Inflatable Boats (Ribs), the Mexeflote landing-raft system powered by the Thrustmaster propulsion unit, workboats, and planned future craft.

The video below shows their operating principle.

Maximum speed is 6.5 knots.

Transport

One of the advantages of the modular design of Mexeflote is that it allows it to be carried by road, rail, air, and of course, sea.

Rail, including double stacking, if the gauge allows.

Road

As can be seen by the images above, each module has multiple lifting points.

They can be carried as deck cargo and craned overboard individually or as a unit, as shown below.

Connecting pieces are secured to connect the pontoon modules as required.

They can be carried inside a ship with a well-dock, like the Bay or Albion class of amphibious vessels (although this is less frequent)

Mexeflote also has a unique method of carriage on amphibious support shipping and sideloading.

Sideloading makes use of an inclined hull-mounted support bracket and securing fixtures to carry one or two Mexeflotes as a ‘saddlebag’, secured to the vessel hull for transit.

RFA Lyme Bay with sideloaded Mexeflote show below.

Sideloading preserves finite deck and dock space.

Upon arrival at the end location, the Mexeflote was originally ‘free dropped’

On the Bay class vessels (and HMAS Choules below), deployment is done under control.

The securing fixtures are removed when deployed.

The propulsion units and control cabin (Wendy Hut) are then lowered and secured.

Naturally, the sea state will limit this, but it is an ingenious method with much utility.

Recovery is the reverse of deployment.

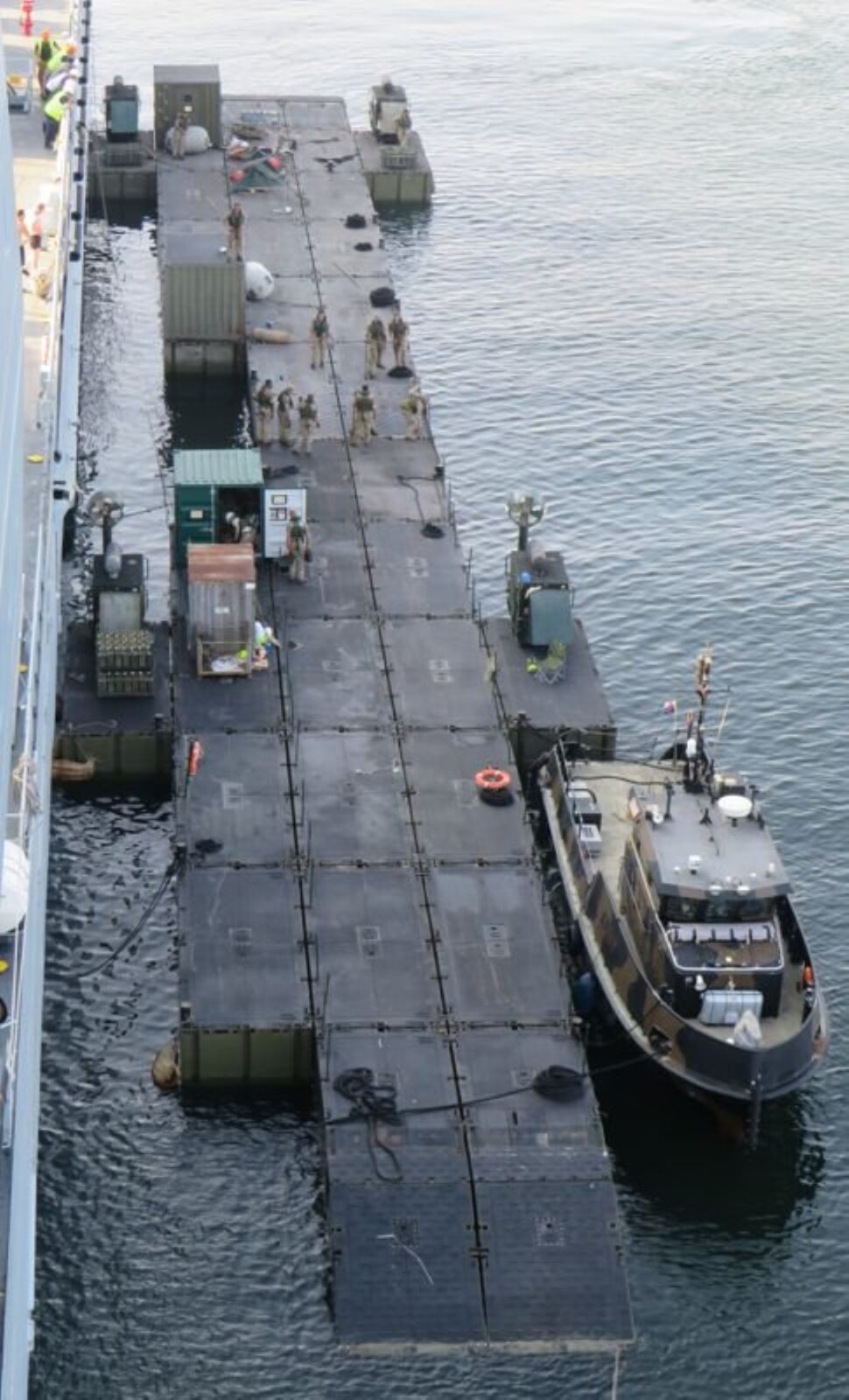

Configurations

The modular design of the Mexeflote provides an almost unlimited number of combinations within its load and joint capacity.

Powered Raft

The most common use of a Mexeflote is as a powered raft to move vehicles, equipment, and stores from amphibious shipping to shore.

This is usually in one of three configurations.

- The Type A is 20.1m long x 7.4m wide, capacity of 60 tonnes

- The Type B is 38.4m long x 7.4m wide, capacity of 120 tonnes

- Maxi Mexe is 38.4m long x 12.2m wide, capacity of 120 tonnes

The A and B types are the most common as they can fit across the Bay and Albion class well dock for loading and unloading.

Type A

Type B

The four-module-wide Maxi Mexe is shown below

The hinged bow forward section allows the Mexeflote to access different beach angles and boat or RORO ramps.

Shallow slope angles such as this at the Marchwood Sea Mounting Centre.

Or a steeper ramp, as shown in the image below.

When accessing a beach, it is common practice to use a Class 30 Trackway with JCB Medium Wheeled Tractor and trackway dispenser.

Mexeflote is designed for very shallow water but some terrain or local conditions and requirements will force even a Mexeflote some distance offshore, such as Haiti, shown below.

Where no suitable ramp or beach exists, and tidal ranges result in height differences between the Mexeflote deck and harbour facilities, telehandlers and forklift trucks can be used to transfer pallets, materials, light vehicles or stores.

Suitable link spans can also be used if height differentials are not significant.

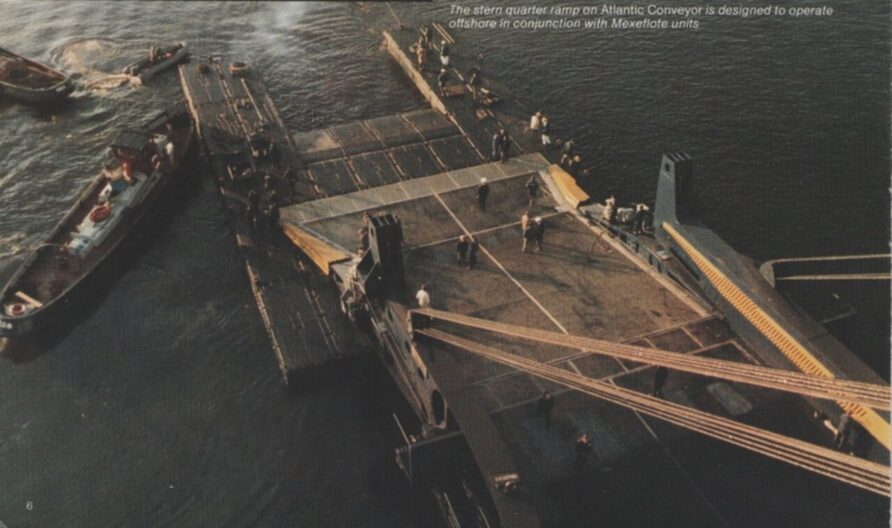

Ramp Support Platform

A ramp support platform configuration was used from its first introduction.

This provides an intermediate platform that supports the weight of an amphibious vessel ramp. Other vessels can also land their ramps on the platform and use them to move stores between each other, whilst maintaining a safe distance and avoiding using cranes.

It was used during the 1982 Falklands Campaign. The method also allows smaller vessels such as Landing Craft and other Mexeflotes to unload the ship without it having to continually raise and lower the ramp.

After the Falklands Conflict, the replacement for the Atlantic CONRO vessels (ACL G3 Class) was also extensively trialled with Mexeflote Ramp Support Platforms.

More recently, the Point Strategic RORO vessels have also used Mexeflotes as a ramp support platform.

Fuel Pontoon

As a component of the Ship to Shore Pipeline System and wider Joint Operational Fuel System (JOFS), Mexeflote pontoons can be used to support pumping and manifold equipment, mooring dracones or other pipelines.

Causeway

Mexeflotes can also be used as a floating causeway or link span.

These allow a landing craft to dock with the Mexeflote and load or unload without beaching or negotiating the surf zone.

The propulsion unit is offset to allow ‘drive through’ and the pontoons are secured to the beach with appropriate anchoring.

The image below shows the offset propulsion units.

Other

Mexeflotes can also be used as work platforms or small craft mooring platforms.

It has numerous uses.

Replacing the Mexeflote

The first two questions are: Do they need replacing and do we want to replace them?

Because they are relatively simple in construction, they can be maintained for the long term, replacing or adding individual components as needed.

Of more significance is the question of want.

There is no doubt the Mexeflote is joined at the hip to whatever wider aspirations the UK has towards amphibious and littoral capabilities and the subsequent big questions about the future of 3 Command Brigade and Royal Navy and Royal Fleet Auxiliary amphibious shipping.

Without knowing the answers to these broader questions, it is not possible to articulate clear requirements, but there are a handful of options worth considering if the Mexeflote capability is to be retained in some form.

Refurbish

The easiest option is to just keep the fleet going, refurbishing as needed under the wider maintenance contract with Barrus.

Landau Marine has recently done just that

We might reflect on the lack of equipment care that seems common across the wider MoD, but in this case, Landau has shown what is possible.

A completely new epoxy paint system was introduced, as were new non-slip decking with many samples sent to the end user to make sure we hit the right combination of grip and durability. New hatches and stainless bolts were made and fitted and the whole area was blasted back to metal and then resprayed to help prolong life. Areas which had become completely rusted over were made good with new deck plates being welded in place. Even the detail of marking the bolts so the end user had instant visibility of tampering. And finally, the inside of the Mexeflotes were completely cleaned out, blasted back to metal and new paint applied

Additional Features

Beyond basic refurbishment, the capability, and usability of the Mexeflote could be expanded and enhanced.

Candidates for this could include improving the side loading arrangements on whatever comes after the Bay Class to increase sea state operability and improve safety.

Wireless remote control for the propulsion units might reduce the crew demand and improve safety, the same as improved portable navigation equipment intercoms and habitability enhancements for the crew.

A more significant development might be to go back to its Heavy Ferry roots and change the propulsion system to thrusters at each corner, with the machinery held within a pontoon module, perhaps even from the same Tees White Gill company.

Computer-controlled dynamic positioning would be possible, and operability at shallow depths improved also, although the high-speed operation is not a significant requirement, more power is always useful

If these thrusters and their power unit could be built inside the dimensions of a standard centre-section pontoon, roll-on-roll-off operations would be significantly easier without offsetting the existing propulsion units.

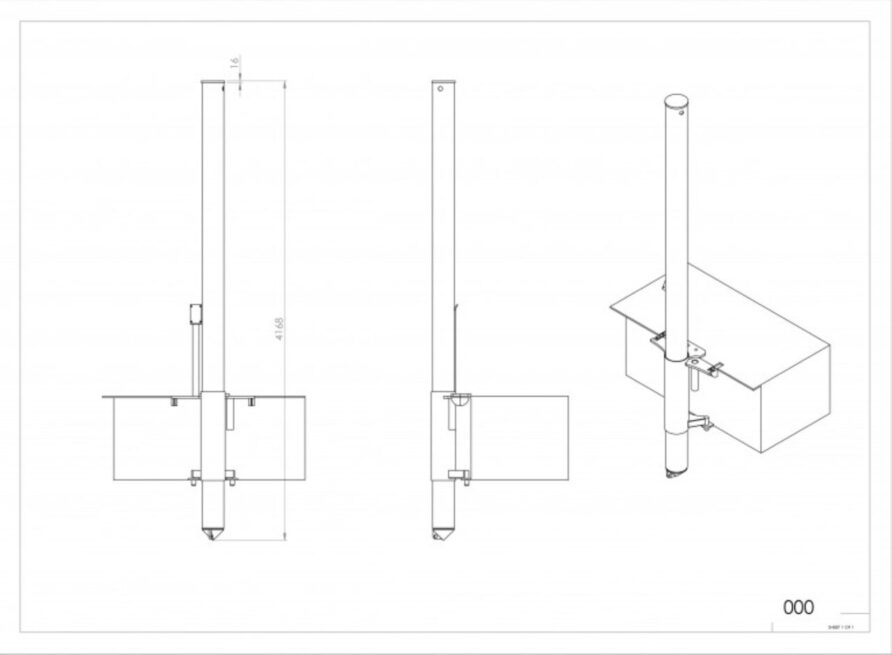

A less hi-tech addition could be spud wells to enable a Mexeflote work platform to be secured to the sea bed. I think Jenkins Marine used to make these for the Mexeflote, but difficult to find any details online.

A spud is a simple steel pipe, generally with one end fitted with a penetrating cone or spike.

They are contained by a spud well, a simple collar that fixes it to the pontoon.

The spud is lowered into the harbour, river, or seabed and under its weight, penetrates and thus secures the pontoon such that it can resist lateral forces, usually from construction or dredging equipment.

Because they are not driven in, removal is usually straightforward with simple hydraulic equipment, some spud wells are also equipped with winches to facilitate removal.

Fitting Mexeflotes with a spud system would enhance their functionality in secondary roles.

ISO twist-locks and an adapter for the EPLS hook lift system would also ease intermodal transportation problems.

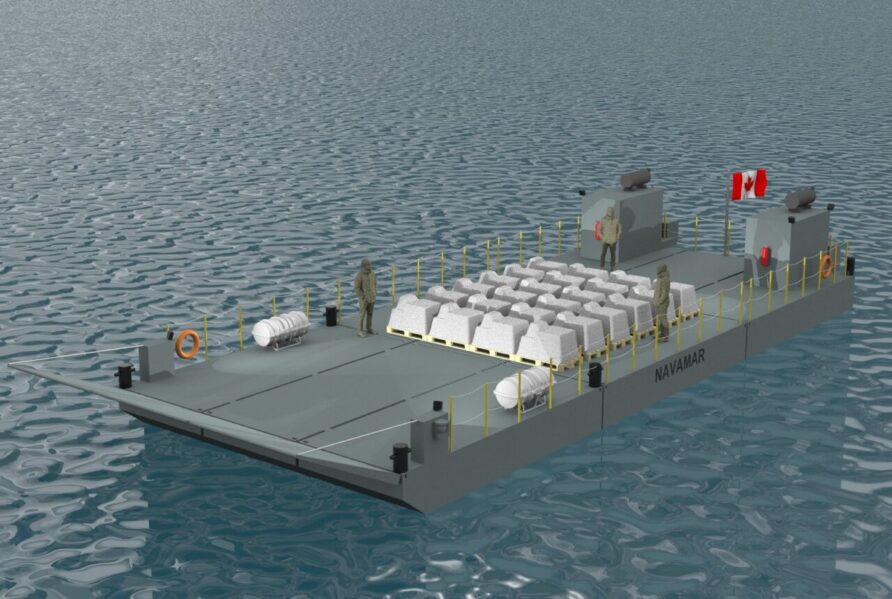

Navamar Sea to Shore Connectors

The Royal Canadian Navy (RCN) investigated Mexeflotes for use with their Joint Support Ships (JSS).

Navamar was awarded a CAN $11.8m contract to design and build four systems.

The system is a modular self-propelled pontoon barge, and comes in two configurations: a 3 × 3 and a 3 × 4 version. It has a maximum cargo capacity of 81 tonnes, is capable of carrying sea containers, personnel, or large vehicles. It can be beached with a roll-on roll-off ramp forward, reach speeds of 5 knots, and is extremely manoeuvrable with directional thrusters.

The basic Mexeflote design was adopted with some changes made, especially the bow section. Instead of a bottom-hinged articulated ramp, the SSC has a top-mounted ramp.

The SSC is smaller and with reduced capacities compared to Mexeflote but is a current system, designed with containerisation in mind.

As can be seen in the video, the propulsion equipment and ramps fit inside a standard ISO container.

“We originally wanted help in using the sea-to-shore connector tactically, but we have tapped into the UK’s knowledge and opened a full Pandora’s box in what can be done with them,” says Lieutenant-Commander (LCdr) Rowan Wilson, Executive Officer and Staff Officer New Capability and Training at Naval Personnel and Training Group (NPTG) Headquarters. “We are currently just scratching the surface of this cool new capability and hopefully it will get more people excited about what the Navy is doing.”

The pontoon modules will be stored on the deck as standard containers.

General Dynamics Pontoon Boot (POBO)

A system worth a look is the General Dynamics European Land Systems ‘Pontoon Boot’, or PoBo.

This was a development project primarily designed for inland waterways supporting disaster relief, operated by the Federal Agency for Technical Relief (THW).

Again, not as high capacity as the Mexeflote, or tested offshore as far as I can understand.

More video here

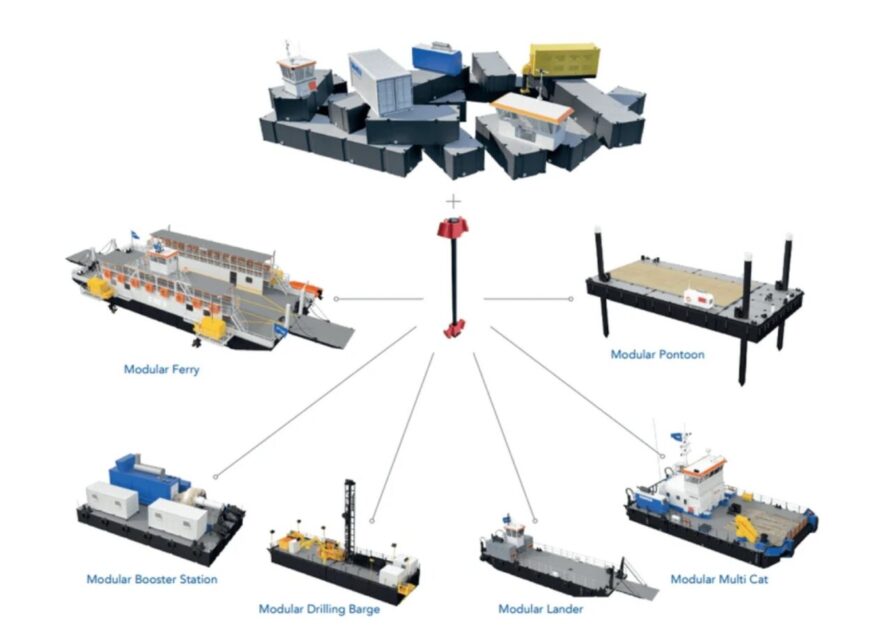

Large Modular Pontoons

Large modular platforms are available from many manufacturers, including Volker Brooks, Janson Bridging, Damen, Hann Ocean, Robishaw Engineering, Combifloat, Modular Pontoon Systems, Intermarine, Innovo, Baars, Poseidon Barge and Ravenstein.

Damen has a rather smart pontoon configurator for its extensive range.

As can be seen from the image below, the Damen Modular Pontoon has ISO twist locks at each corner

Most of these tend to be larger than the Mexeflote pontoon and are mostly focused on inshore activities such as port construction or bridging.

Scaffloat

Scaffloat and Workfloat is a UK-designed and built system for smaller applications that uses scaffolding components and plastic pontoon cubes.

I wrote about this system in 2022

Summary

The Mexeflote is an incredible system that despite being over 60 years old has endured in its original design and concept of employment.

Australia and Canada have more recently adopted the same or similar system.

The core attractions of Mexeflote are its simplicity, adaptability, and capacity.

With all that said, its future seems intertwined with the UK’s amphibious future.

Probably the most sensible course of action would be to carry on with it, refurbish and keep them well maintained, with perhaps one or two enhancements if budget allows.

There are larger systems, and there are smaller systems, but I think those chaps at MEXE got it fundamentally right.

TD, a very interesting read. Thank you.

Another excellent piece, as a former RM I thought I knew about Mexeflotes – apparently not! Surely these would be the answer to the Gaza port issue and I'm sure Marchwood would jump at the chance.

Hopefully, mexeflote is interoperable with other commercial systems so in an emergency they could be mix'n'matched.

An excellent read and thought provoking article. As an ex Army Marine Engineer, who not only operated and maintained these systems but also saw the development, over time, of the systems used on board and the various propulsion units, between 1976 to 1999 it would be devastating to see MEXE done away with like so many of our other capabilities that have been lost never to return. The ship to shore amphibious capabilities of the UK Armed Forces will be a lot poorer without MEXE and those skilled Army Mariners that operate it.

As an ex operator of Mexe for 14 years I can honestly say and I’m sure my hundreds of brethren from the regiment Will all say It’s beauty is it Simple and rugged construction. It functions in Any theatre and even in some when other systems fail, it needs basic maintenance and a good crew. On an exercise in the mid 90s In Chesapeake Bay, United States, our Mexe crew Delivered our cargo to the beach when American assets could not operate because of storm weather. It moves massive amounts of equipment and with its side loading capability doesn’t take up deck space apart from its ancillary equipment If it ain’t broke, don’t fix it

Coastworks who are based in Scotland own 42 Mexeflote sections. They named them CW-5 inline with their other barges/pontoons. See: http://www.coastworks.co.uk

Thanks Brian, would you mind if I nicked a few of those images for the next revision, especially the ones with spudlegs?. Will credit of course

Hello, thank you for your email. I'd be happy to send you better photos and many more if you want. Feel free to email me direct and I will send you some photos back. Our Facebook and Instagram pages have much better photos than the website.

Some great images on your Facebook Brian, I will use a couple of those if its OK

The Canadian system is a powered barge built under the Ship-to-Shore Connector project (https://rusi-ns.ca/ship-to-shore-connector/).