In the previous post on what could replace the FV432, I concluded that if it were replaced, given the relatively narrow range of roles it now performs, it would probably be replaced with Boxer modules or Ajax variants.

I also touched briefly on the origins of the FV432 as a protected tracked load carrier, the FV421 shown below.

Stalwart was developed as a high-mobility load carrier, selected over the FV431.

Both were designed as close support logistics vehicles for armoured forces.

Today, the MAN SX Improved Medium Mobility (IMM) trucks are in service.

They are available in relatively small numbers (and now replaced by HX/HX2/HX3), the original order was 90% of the lower mobility HX versions.

One could also argue that for close support, they are not as mobile as the vehicles they would be supporting and without any form of protection, somewhat limited utility. Tracked vehicles usually come to wheeled vehicles for resupply, but mobility is never a bad thing, and this comes into sharp focus if we are operating in northern climes.

As we have seen amply demonstrated in Ukraine, rain and mud are significant obstacles to overcome for any vehicle, tracked or wheeled, especially if the ground has been repeatedly trafficked.

If there is to be a replacement for FV432, I propose that it should go back to its FV421 roots.

Take a detour through Stalwart Street, nod to Ukraine, look left to the High North, and settle on a High Mobility Load Carrier (Protected).

In the majority of cases, a ‘Commercial Off The Shelf’ solution (COTS) vehicle is unlikely to be as good as one designed from scratch for military use, but they will tend to be cheaper.

In a world of finite resources, we can look at a COTS vehicle’s shortcomings (and there will be plenty) and ask if they can be accepted where cost and time into service are factors.

Two COTS vehicle classes are relevant, tracked utility carriers and articulated dumpers.

The FV432 weighs approximately 15–18 tonnes and is 5.5m long, 2.55m wide and 2.3m high.

The payload is approximately 4 tonnes.

2.55m width is a key dimension (or 8 foot 4 inches (0.1 m)) because it is the maximum allowed width for any vehicle on UK roads (unless it is refrigerated) or they will require special arrangements. However, Road Vehicles (Construction and Use) Regulations do make provision for a maximum overhang of 305 mm when a vehicle is being carried on, for example, a flatbed trailer, the maximum allowable width becomes 2.9m.

Stormer is just under 2.8m, Warrior, is just over 3m.

The British Army is not well provisioned with trucks and trailers that can carry the FV432, so keeping within similar dimensions and weights would at least mean no increase in transport burden.

This leads to an outline requirement for a very high mobility COTS vehicle less than 2.9m wide, with a payload of 5 tonnes or greater.

Two types can be considered, tracked utility carriers and articulated dumpers.

Tracked Utility Carriers

Tracked Utility Carriers are widely used in oil and mining, pipeline installation and energy infrastructure sectors, often in harsh climates and extreme terrain.

Manufacturers include UTV, Foremost, Prinoth and All-Track in Canada (for Prinoth, Italy also), and Kässbohrer Geländefahrzeug (Power Bully) in Germany, joined by Loglogic in the UK.

Loglogic in the UK manufactures three models, the Softrak 75, Softrak 140, and Bigtrak.

The Bigtrak has a payload of 5 tonnes and an empty weight of 6 tonnes.

Each of them is easily transportable.

Maximum speed is only 16kph.

A closer match to FV432 dimensions would be the Prinoth Panther T6 or the Powerbully 9C

The Panther T6 bare chassis is 4.92m long and 2.4m wide with mirrors folded. It has a payload of 6.99 tonnes and a gross vehicle weight of just over 14.5 tonnes.

A load bed is not included in these weights, so it would reduce payload.

A 1 or 2-person cab and various tipping bodies or integrated payloads can be fitted.

The load bed is 2.2m wide and 2.5 long, although a metre-long extension can be fitted. Without the extension, four standard NATO pallets could be carried.

They are easily transported using conventional trucks and trailers.

The Powerbully 9C is similar to the T6, 5.44m long, and 2.45m wide.

It has a payload of 9 tonnes and a gross vehicle weight of 19 tonnes.

As with the T6, a load bed is not included in the weights.

The load bed space is 3.1m long, a 900 mm extension can also be fitted.

The 9C also has the same Cummins 6.7L engine as the Supacat Jackal.

All the manufacturers linked above have larger models with much higher payloads.

The Foremost Nodwell 110 is 7.1m long and 3.0m wide (although 2.6m without tracks to enable road carriage). It has a payload of 10.45 tonnes and a gross vehicle weight of just over 24.3 tonnes.

The larger Nodwell 320 has a payload of 25 tonnes and a deck length of 6.9m, big enough for a 20ft (ca. 6 m) ISO container.

They are work-class machines built for the harshest of environments and toughest terrain.

But, they are slow.

Where the FV432 is much better than either of those above is maximum speed. At 50kph (ish) it is much faster than the T6 with a maximum speed of 16kph or the 9C with 15kph.

More conventional tracked dumpers from Yanmar, Marooka, and others are available, but these tend to be even slower.

The lack of speed is potentially the Achilles heel of this type of vehicle, either accept it as a limitation, try to modify it (perhaps not the best idea or even possible without adding complex suspension systems) or not bother.

Articulated Dumpers

Medium-sized wheeled articulated dumpers (with a flatbed) bridge the mobility gap between on-road and off-road.

Top speeds tend towards the 35-45kph range.

Even though they are articulated to maintain wheel contact with the ground on uneven terrain and have off-road tyres, they are unlikely to compete in extreme terrain with the tracked utility carriers described above.

The compact Hydrema 707 is a good example at the smaller end.

The 707G weighs 5.4 tonnes and can carry a 6-tonne payload.

It is 5.3m long and 2.55m wide.

The tipping body can be replaced with a flat load bed, although an extension would be required if more than two pallets were to be carried.

At less than 11m for two, they are also easily transported.

The 707G can also be fitted with Moorend Tracks

Two slightly larger examples are the Hydrema 912 and Bergmann C815

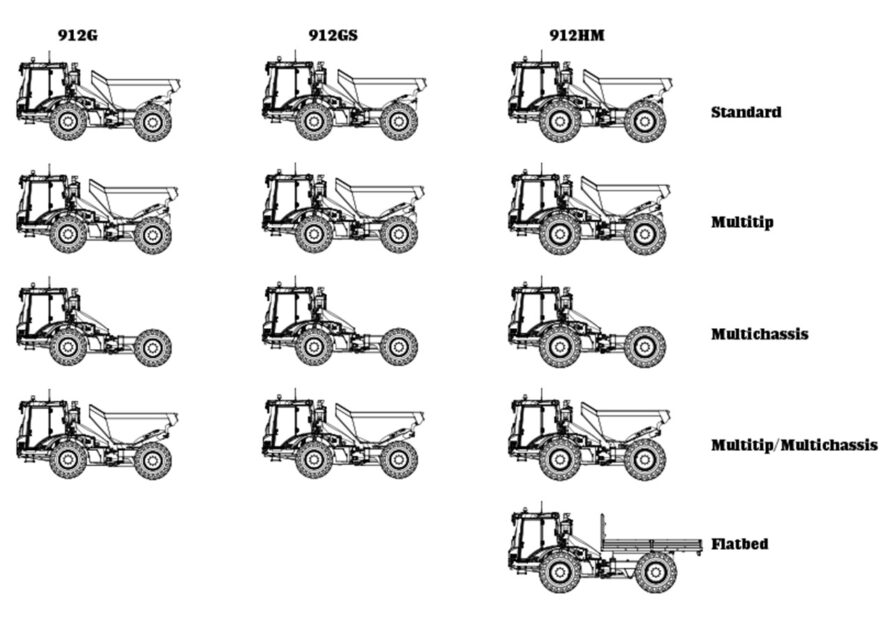

The well-established Hydrema 912 is available in different variants.

The 912HM (High Mobility) has sprung front wheels, wider tyres and a longer chassis.

The chassis is longer and can accommodate a flat load bed.

It is 7m long and 2.8m wide with mirrors folded. It has a payload of 10 tonnes and a gross vehicle weight of just over 18.3 tonnes.

Like the 707G, Moorend has also shown it with tracks.

Shown below in the video.

The Bergmann C815 is 7.6m long, and 2.54m wide, has a payload of 12 tonnes and a gross vehicle weight of just over 22 tonnes.

Longer, heavier and with a larger payload than the Hydrema, but does keep within the 2.55 mm width limit.

Payloads, Cargo Handling and Trailers

Although those vehicles described above are focussed on simple load carriage with a fixed load bed, any of them with a flat space can have utility expanded.

The most obvious would be to add a hook lift for demountable flat racks and short containers, only for the larger vehicles.

Cranes, work platforms, well drilling rigs, concrete mixers and service modules have all been demonstrated on them.

Tracked and wheeled trailers can also be used.

It is also not an impossible stretch to see any of these vehicles above as a carrier for a C-UAS system, a portee for artillery guns, similar to the Thales Rapidfire system below.

Protected Cabs

We know we can put a protected cab on construction vehicles, it was done in a few months with Afghanistan UORs, and relatively cheaply.

If we treat high mobility vehicles as a C Vehicle, it should be easy to envisage just how quickly they could enter service with a protected cab.

There are examples of simple personnel carrying cabs

Whilst I would not specifically advocate a demountable cab to replace an APC, containerised personnel carriage systems are available.

Summary

Admittedly, any of the above would be a stretch to bring into service.

None of them are statements of war, but the point of this post is to demonstrate that if the many shortcomings of COTS high mobility load-carrying vehicles are accepted.

There is a path into service that is quite fast and relatively cheap.

I guess it depends on how much thought we are giving to heavily trafficked mud.

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

Might trackways and rapid surface preparation merit consideration following this article? Welcome your thoughts.

Always James, but there is a penalty of time, cost and visibility to consider

what suspension changes would be needed to increase tracked vehicle speed. many look like they have torsion bar suspension but only 4 wheels a side instead of 6. what do mtlbs and fv430s have to deal with higher speed. Many of these vehicles have hydraulic powerplants which are slow, but hybrid electric drives are becoming far more common and are faster while being quite simple.