Building on a handful of earlier posts on infantry load carriage, quad bike ATVs and the Container Delivery System, I thought it might be interesting to evolve some ideas and concepts they described.

Risk and Requirements

To start this post, a few words on risk.

Haddon-Cave didn’t happen for no good reason, every line of safety legislation is written in someone else’s blood (and that someone is usually a working-class someone), and despite service personnel accepting more risk than many, it doesn’t mean that acceptance should be taken for granted.

This means safety (and liability) is an important factor in decision-making. Naturally, the risk acceptance pendulum tends to swing further in one direction in peacetime than it does in war.

Nothing is wrong with this, it is the natural state of things.

This means there will always be several barriers that make simple and low-cost solutions to almost anything entering service, i.e. the ratio of process cost to solution value.

We also have to be realistic about that value, trailers, and handcarts are not main battle tanks or precision-guided weapons, there are no SO2 Trailers.

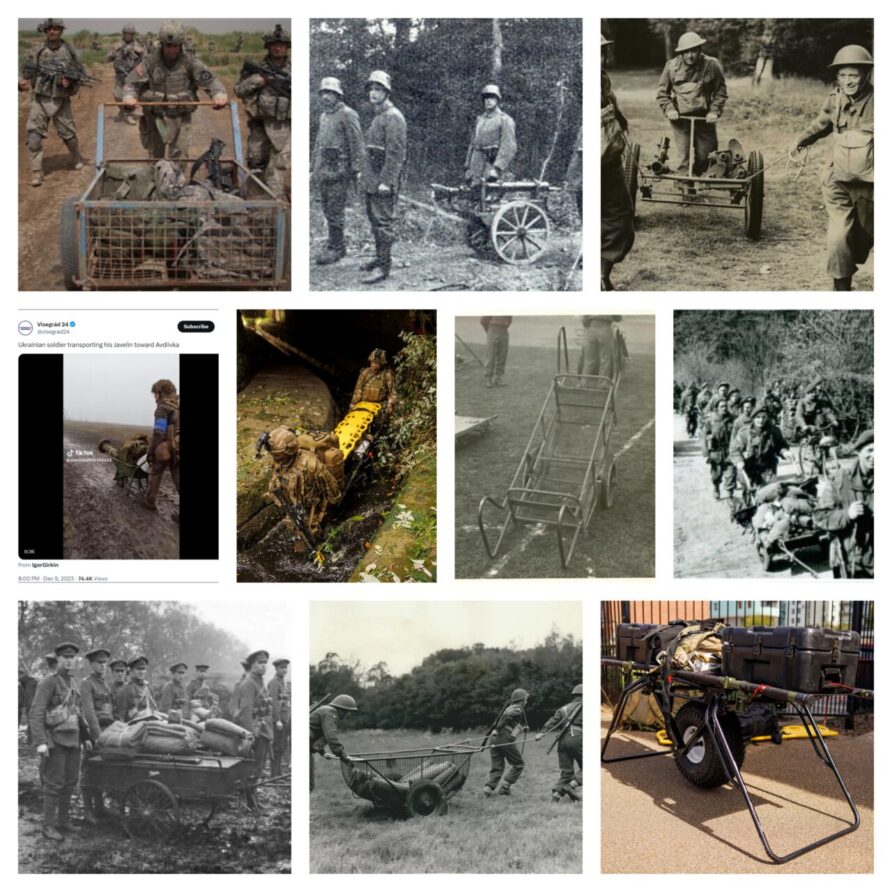

In a world of artificial intelligence, uncrewed systems and advanced weapons, it is easy to lose sight of one of man’s most simple, enduring, and impactful defence inventions, the wheel.

Instead of carrying heavy and bulky loads, they can be wheeled around with much less effort, it is as simple as that. For dismounted and light-role infantry, they provide a low-cost capability that allows them to move greater distances with less energy and much greater efficiency than without. They can force soldiers to take predictable routes but like anything else, they must be used properly.

In pretty much every conflict since the wheel was invented, simple hand-pulled carts and small trailers have proven their value, especially for light role and dismounted infantry (although other arms benefit as well)

When conflict recedes into the distance, they tend to be forgotten or other priorities found, value does not exceed the process drag.

The wheel then turns (no pun intended), and its value overcomes process drag.

The problem is that units never benefit in the early stages of any conflict, and solutions may not always be available in sufficient time.

A Different Approach

There are many methods of getting something like this into service.

The conventional route establishes a requirement and then moves it through the ‘concept to contract’ process.

All the normal diligence and commercial practices would need to be followed, either in selecting off the shelf or funding the development of a bespoke product, and a support contract would eventually be let as i.s

This would be preferred, every last drop of utility and optimisation could be wrung out of the basic idea.

There are many fantastic manufacturers out there and many great designs.

Commonality and interchangeability would be maximised, and the best features of all those examples used in the design.

Does anything think that is remotely feasible?

Despite acquisition reform that has simplified acquisition processes, in short, it still becomes a ‘big thing’ for what is in reality a small thing’

So I think devolving this to soldiers (and civilians) at a unit level could be a possible way forward, the Adaptable Load Carrier becomes the Adaptable Load Carrier (DIY).

A DIY, or self-build, approach is based on three assumptions.

- REME Light Aid Detachments, Royal Engineer trades, vehicle maintenance civilians in Army Reserve locations, and soldiers with applicable fabrication skills exist.

- Those soldiers and civilians can access simple tools and facilities to fabricate basic structures, no CNC or large workshop machines.

- The trailers and handcarts would not be used on the road, or at high speeds, so some risks and requirements incumbent with that would be reduced or eliminated

Instead of looking at an infantry handcart, stretcher carrier, pallet trailer, or ATV trailer in isolation, this post will view them all as variations on a common theme, which in the simplest of terms, they are.

It could also be used as a means of prototyping, and if there was enough value, dip back into the process.

Design and Fabrication Methodology

A design and fabrication team could be formed at, for example, the Armoured Trials and Development Unit (ATDU).

This has a resource cost.

Once refined, designs could be hosted on an online ‘Battlebox’ and continually iterated, being shared as ‘organisational open source’.

Components must be low cost, available from local suppliers or online, and likely the same whilst deployed overseas.

They could be purchased from unit funds or with purchasing cards, treated like a consumable item.

Fabrication technique more or less splits left or right, weld or no weld.

Welding a mild steel box section is not a difficult skill to master, and neither does it require too much specialist equipment. Welding aluminium is a little more difficult, but still not beyond the reach of a typical attached RE or REME unit.

But, if the Adaptable Load Carrier is to be genuinely easy for any unit to create, welding is a step too far, so an alternative method is required.

Components (Structural)

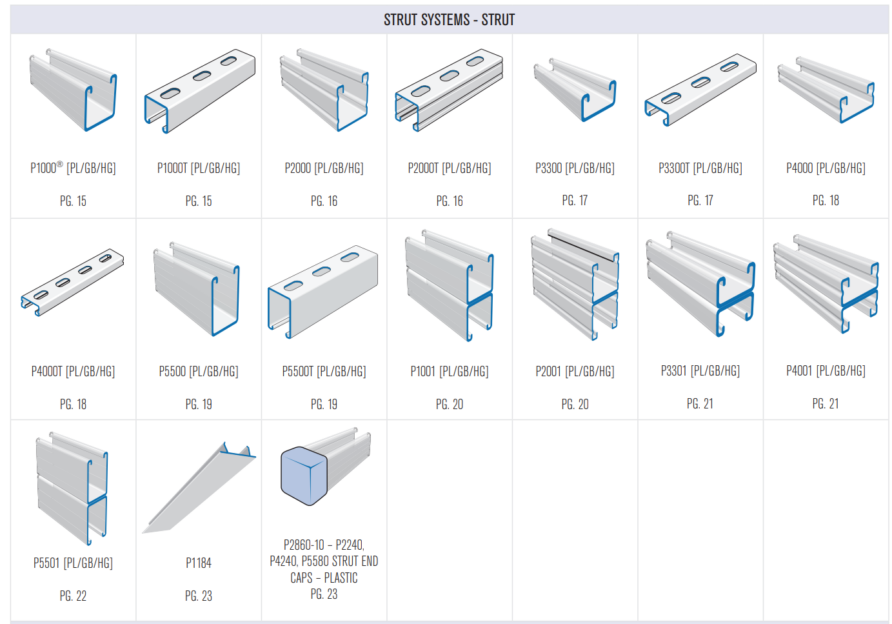

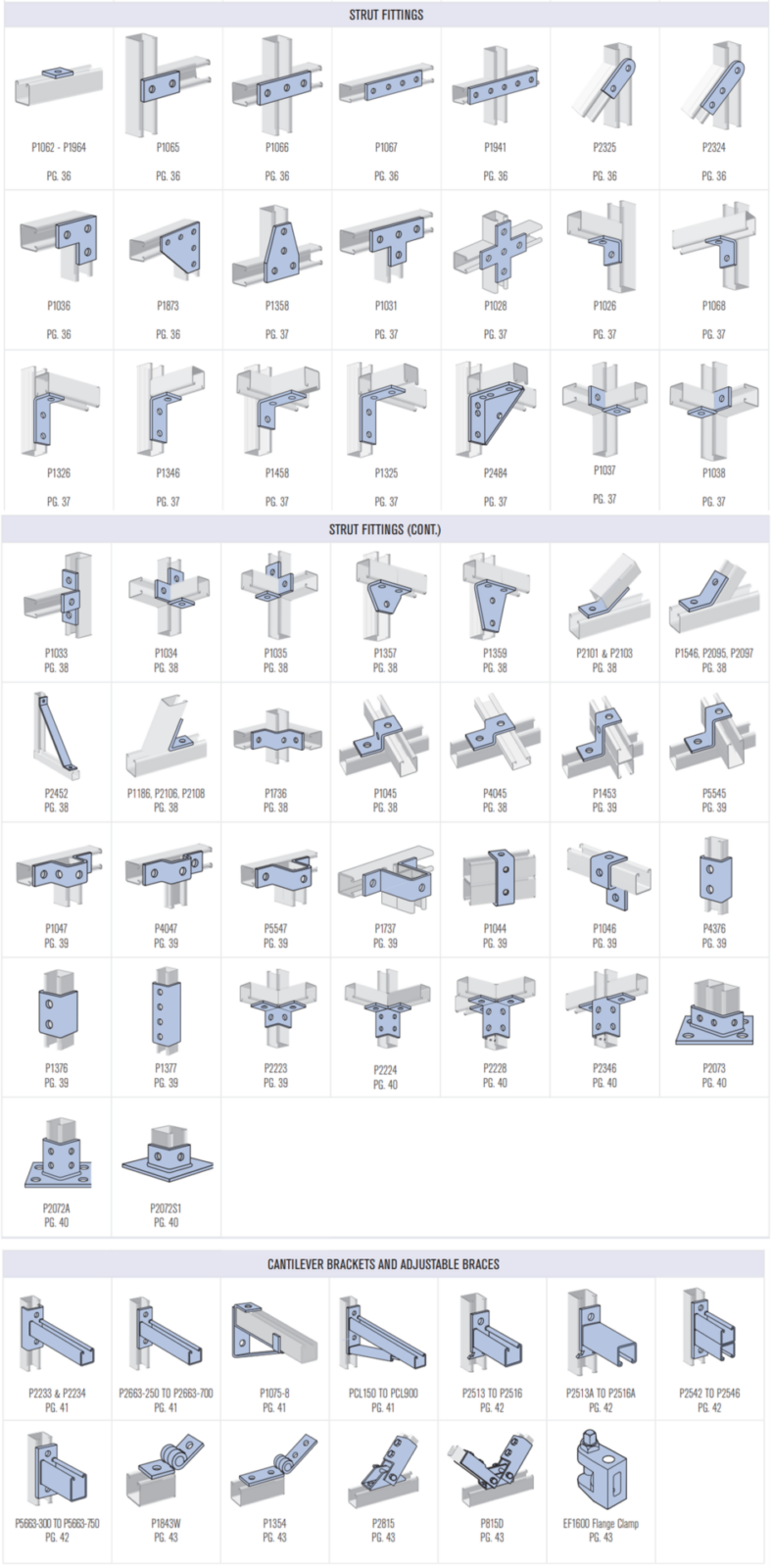

Although there are many proprietary frame connector systems, the three I will consider are commonly available, all easily cut with hand/power tools.

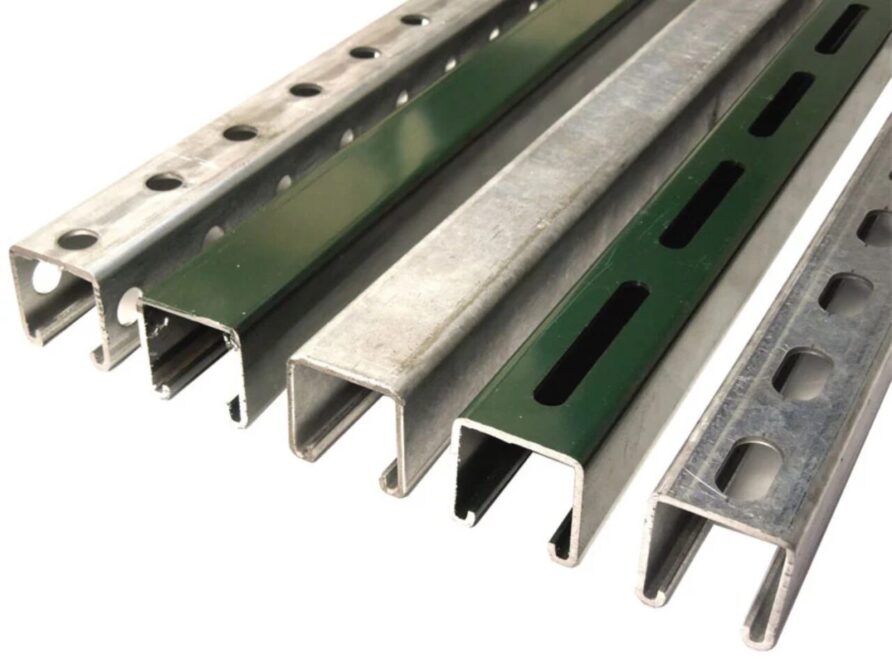

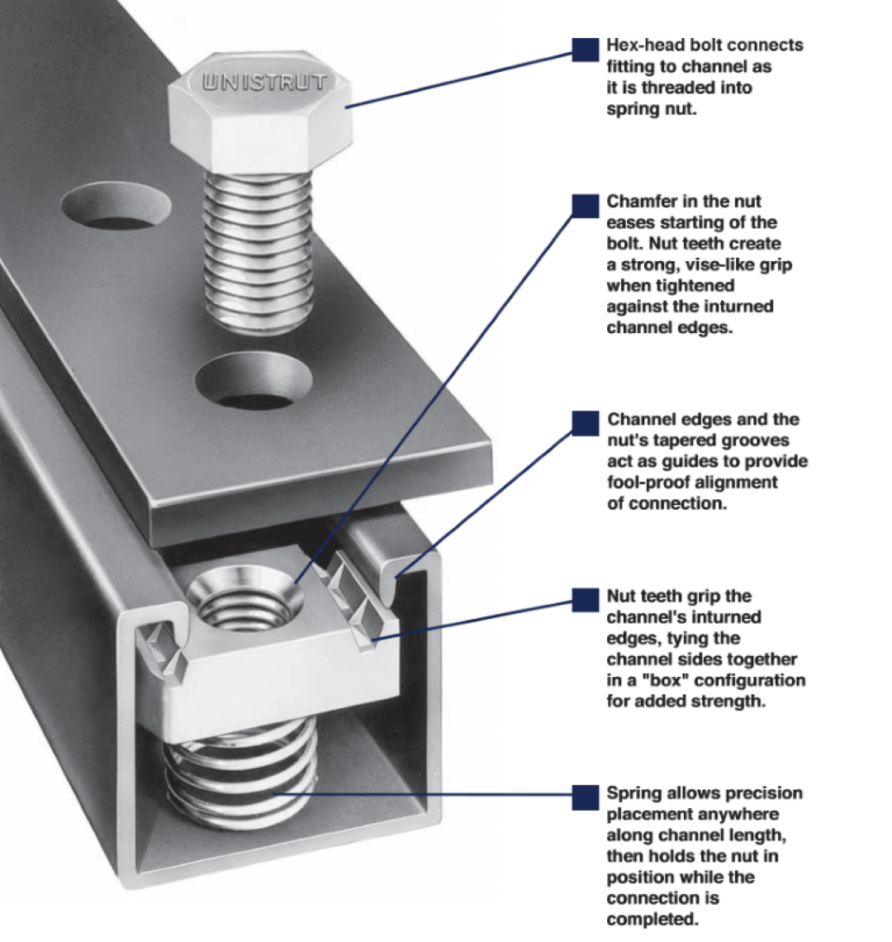

Unistrut/Slotted Channel

Atkore Unistrut is the brand name for a non-weld construction channel, available in pre-galvanised, galvanised, powder-coated and stainless steel.

Single or double, non-slotted, double or triple slotted, it is a widely used and globally available system.

Unistrut is cheap and robust, although not particularly low weight; 2.73 kg/m for 41 mm deep slotted galvanised.

Connectors and fixings are available that allow simple bolt-together shapes to be formed.

A spring nut (zeb) can be used to secure connectors and fixtures at any length on the channel.

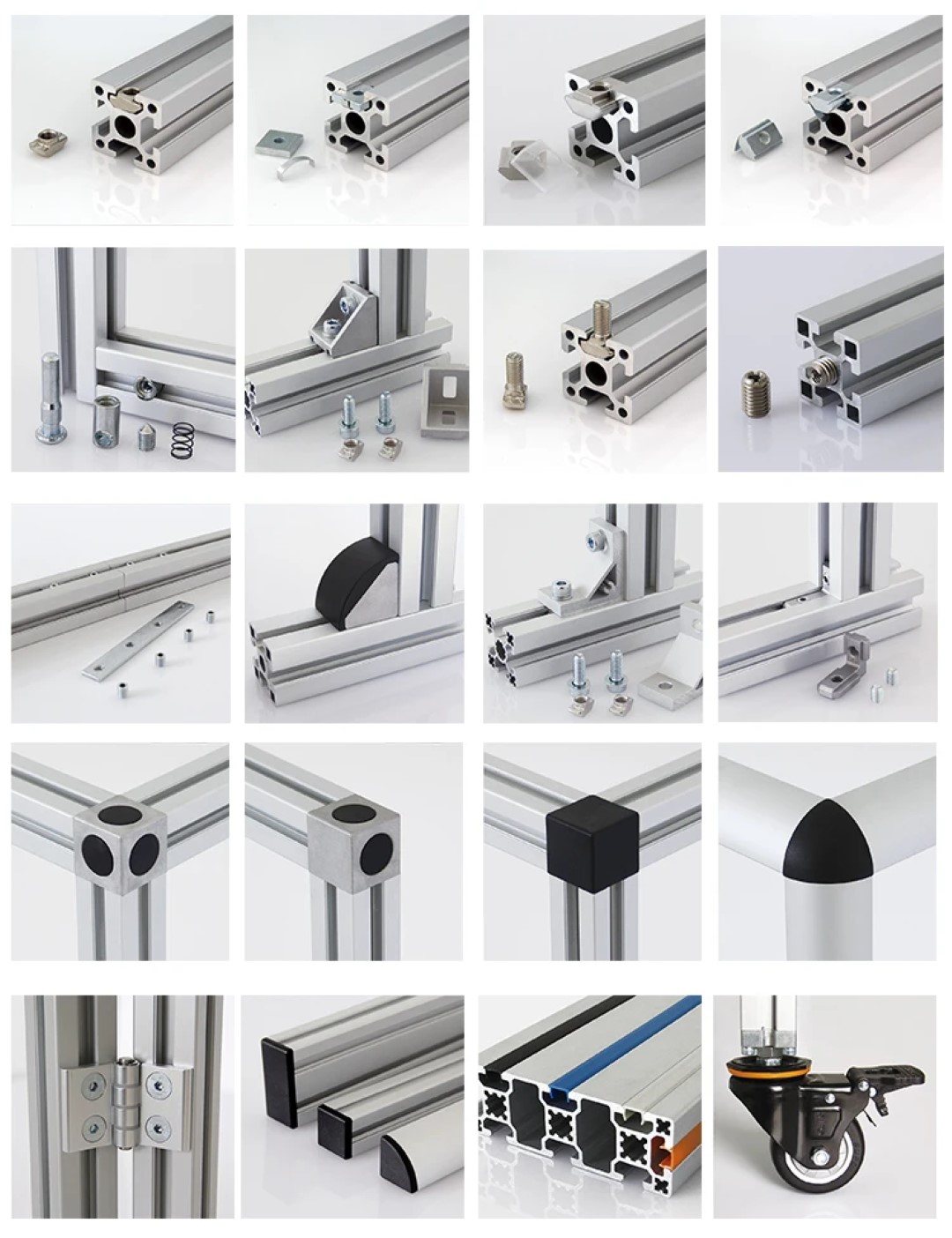

Slotted Aluminium Extrusion

Aluminium extrusion (also called T slot) like that from Bosch Rexroth and many others is a lot pricier than Unistrut-type products but machined to much higher tolerances and available in a much wider range of profiles.

Connecting fixtures allow complex frames to be formed, and secured using captive T nuts that fit inside the profile channel.

The main benefit of aluminium extrusion over Unistrut is its lower weight, 40 mm x 40 mm profile for M6 fixings is 1.74 kg/m

It has more flexible connection options because, unlike Unistrut, the profile channel can be on all four sides, and cut using woodworking tools.

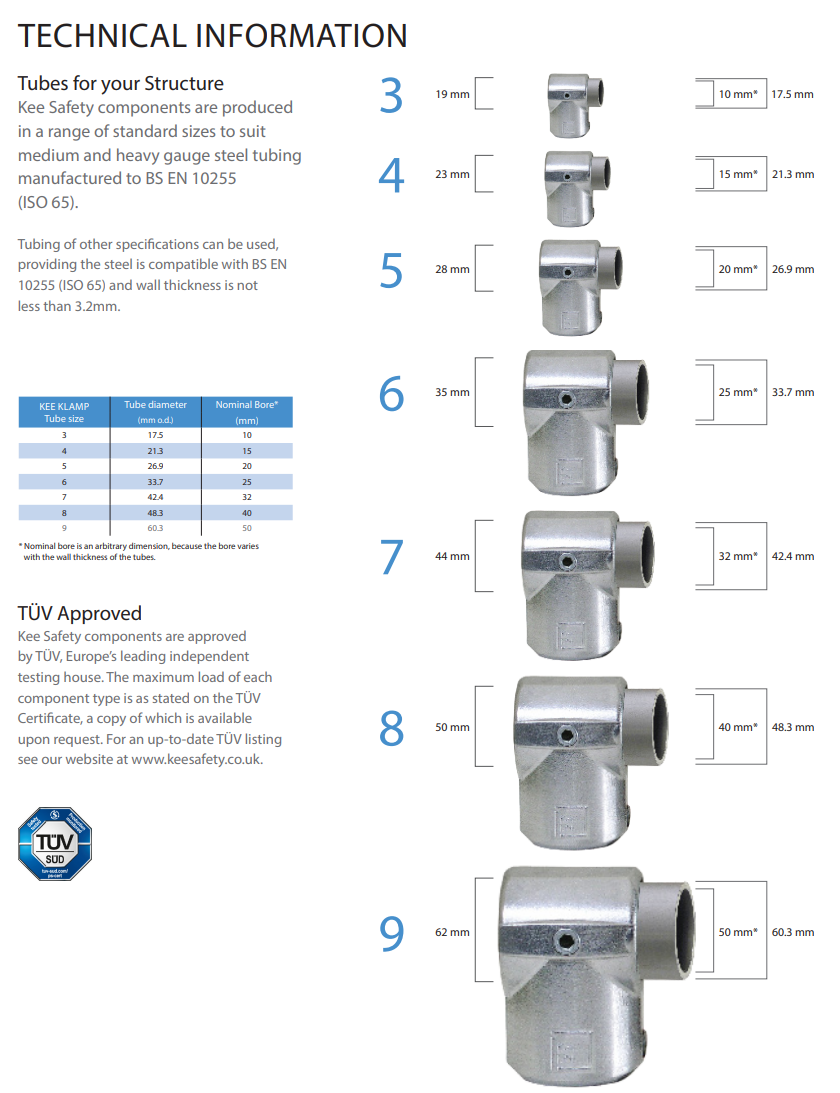

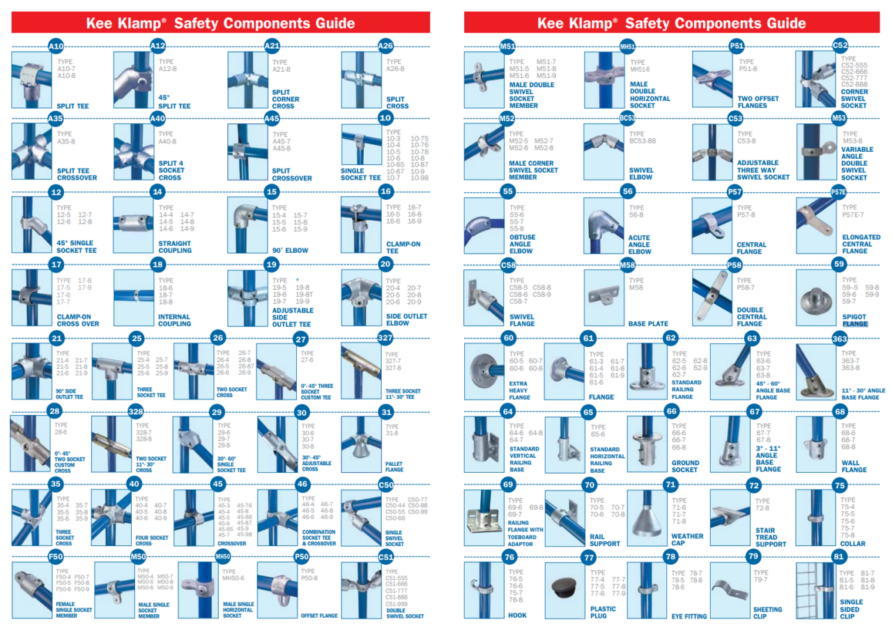

Round Tube and Connectors

Round tube and connector systems, like Kee Klamp, are used for outdoor safety and guard rails, pedestrian barriers, gates, and ramps. Although they have been widely copied and similar products are available globally, Kee Systems is a UK success story with a long backstory.

Tubes are available in galvanised steel, powder-coated steel or aluminium, and in seven size variations, from 17.5 mm to 60.3 mm as shown below.

Tubes are connected using pre-formed connection elements that are secured using a hex set screw, each with an axial load of 900 kg when torqued correctly, a selection shown below.

Different connectors can use various round tube materials and sizes, but 5 mm wall thickness 40 mm diameter aluminium tube is 1.5 kg/m and 3 mm wall thickness 38 mm diameter mild steel is 2.79 kg/m.

Because it is round, a smaller diameter tube can be comparatively as strong as a large square tube, 26.9 mm outer diameter, and 2.6 mm wall thickness, galvanised pipe only weighs 1.55 kg/m

Round tubes are more widely available than Unistrut or aluminium extrusion, and cheaper. Another advantage is that round tubes can be bent using a hand bender, unlike Unistrut or aluminium extrusion.

Components — Sheet Materials

Sheet materials form load beds and provide additional strength and stiffness to structures created by the structural components.

The cheapest practical is probably form plywood, cut to size with basic hand or power tools and fixed into the frame directly or using a frame component

Self-drilling screws or rivets nuts and bolts might also be used.

It doesn’t get any cheaper or simpler than this.

18 mm plywood is approximately 9-19 kg per m2

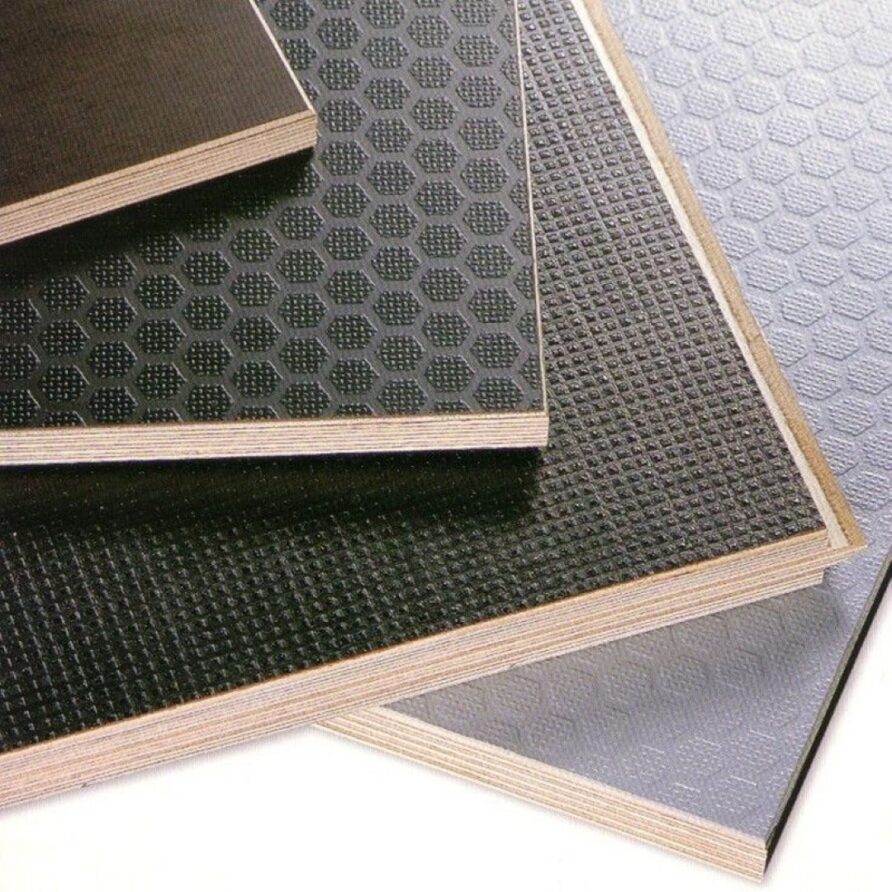

Phenolic plywood with anti-slip embossed coatings like those from Wisa are used for trailer and horsebox floors, van floors and other similar uses.

This would be an improvement over basic plywood, although it is not as readily available as conventional plywood, is pricier and slightly heavier (approximately 14 kg/m2 for 18 mm Hexa floor)

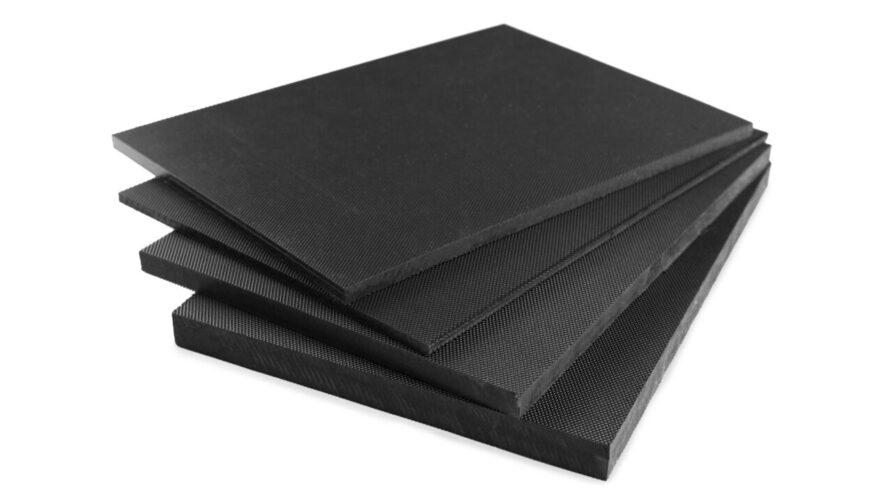

Stokbord is a proprietary product that uses recycled plastic.

Other sheet products that also use recycled plastic are increasingly available, likely much more durable than plywood, although they are more expensive than plywood sheets.

These recycled plastic boards tend to be heavier than plywood, Stokbord is 17 kg/m2 for example, EHB is 11 kg/m2.

Fabric or webbing straps could be used to reduce weight, although they would contribute little to strength and stiffness and would require sewing equipment not likely held in your typical British Army workshop!

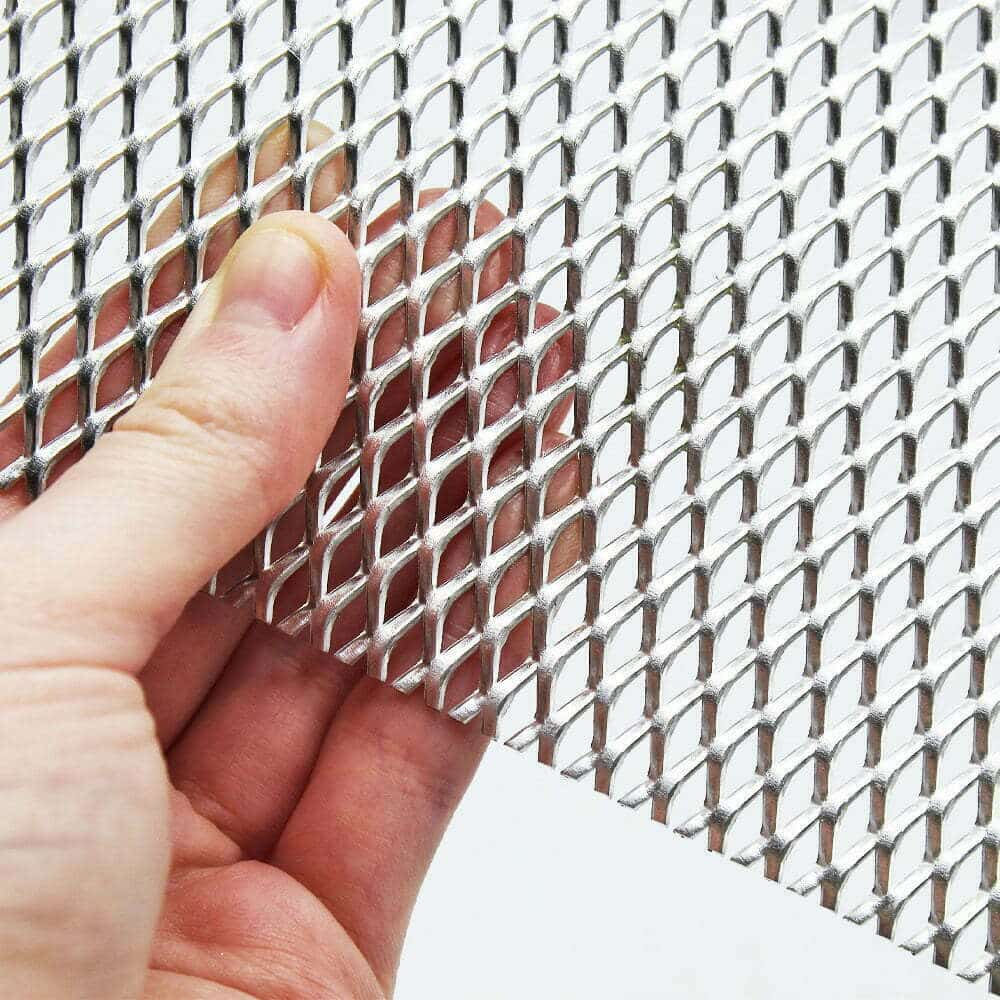

Perforated or Expanded steel or aluminium, expanded aluminium mesh can be as light as 1 kg/m2

Components — Wheels, Axles, Connecting Hardware

Basic frames and load beds can be created with sheet materials and frame systems, but there is an obvious requirement for some specialist components such as wheels, axles, and towing couplings.

These are surprisingly easy to source from online retailers, even Amazon.

Because the working assumption for the Adaptable Load Carrier is that it will have a relatively small payload, and only be used off-road, many of these components can be of a lower specification.

Wheels, tyres, and axles often come as a kit.

For the princely sum of one hundred and 88 of the King’s Pounds, one could purchase this example from Amazon, a couple of ATV wheels with 100 mm Pitch Circle Diameter fixings and stub axles.

Other, and cheaper, online retailers are also available for trailer and cart self-builders. Ross Castors, Indespension and Knottuk are just three examples, each with the widest possible options and good online catalogues.

Whether building an ATV trailer, handcart, specialist carrier for portable bridge components, a pallet trailer or a stretcher carrier, all components be obtained off the shelf.

Components — Load Securing

Load bed material and the frame provide opportunities for load-securing hardware

For many loads, simply screwing a D Ring lashing point into the sheet material or frame and then using bungees, cordage, netting, or ratchet straps would suffice.

Ten quid on eBay for thirty, we could call it a baseline capability!

Expanding on this basic approach, various alternative fittings and fixtures are available, some that are screwed or riveted in, and some specifically designed for the particular frame system.

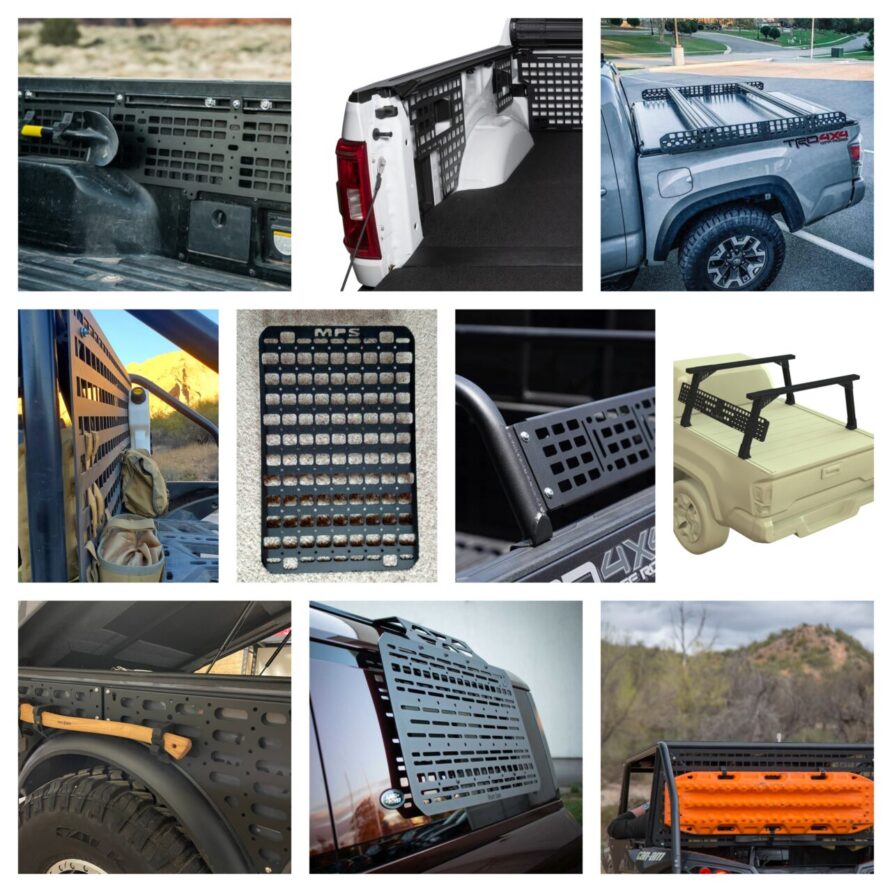

Modular Lightweight Load-carrying Equipment (Molle) panels and strips could be used on vertical load restraint frames. These are available from online sources, although not as many in the UK and USA.

More sophisticated options might be worth exploring, the point of this is to test and prototype using readily available materials and components.

The first would be to optimise the load bed for likely items being carried, an NLAW, stretcher, lightweight bridge or Peli ISP2/Amazon box. The latter uses a 10 cm x 10 cm grid to provide lateral stability, inter-stacking trays can be purchased and screwed directly onto a load bed.

A Koller Engineering floor system with load-securing fixture rails would provide even more options, although probably more sensible to use the fixture rails and either screw them directly into the load bed or frame or, if a router was available, recess them in the plywood (or other sheet material that formed the load bed).

Although these rail systems have origins in the disabled mobility sector, they have been rigorously tested and assured against significant impact loads for wheelchairs and seats.

I have used another image collage below to illustrate the abundance of load-restraining rail systems that are available, none of this is difficult to source.

Components — Pallets and Boxes

The final component will be a surprise to no one reading this.

Instead of building a frame and load bed using any of the systems described above, we could attach some wheels and towing fixtures to a plastic pallet or pallet box, the very essence of simplicity.

I wouldn’t necessarily suggest screwing a trailer stub axle to the bottom rail of a wooden pallet (although it would probably be OK), doing something similar with a half pallet, a plastic pallet or an aluminium pallet could be an even quicker method than a separate load bed and frame.

The above is a crude representation, but hopefully gets the point across!

Want a smaller trailer, cut the pallet in half, bigger wheels for hard surfaces, choose a different set, or remove the towing eye and replace it with a handle?

Need a handle?

Pop into the camp gym and steal some D handles with a bit of cordage or webbing.

Plastic or aluminium pallets are available in a much wider range of sizes than many think, but even sticking with the standard sizes provides a good range, and they are not particularly expensive or heavy.

A 1200 mm x 800 mm ultra-lightweight pallet, shown below, would probably need some form of sheet material fixed to it to provide enough rigidity, but it only weighs 3.2 kg.

A pallet collar could provide side support if required.

If sides and a lid were important for the application, dispensing with a pallet and using a pallet box would be just as easy. Pallet boxes are available in the same range of sizes, materials, and colours as flat pallets, and used to move small things in bulk, fruit and vegetables, small parts, waste materials etc.

From a 200 litre half pallet size nestable Hogbox

To a 2.16m × 1.0m, 1,120 litre Dolav ACE SL2160

A 1000 mm x 400 mm stacking box

And an even smaller 600 mm x 400 mm Eurobox

They will all have enough strength and rigidity for most applications.

By using these standard-size boxes, the industrial ecosystem that exists around them can be exploited.

An example would be disposable liners, commonly used to transport liquids such as fruit syrups and chemicals, but also fuel and water.

The US Army used similar a few years ago for air despatch, called the Lifeliner CUBE.

The JMIC system could also be given wheels

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Final Thoughts

Nothing above is war-winning, but if it adds value, even if that value in the grand scheme is relatively minor, it is worth looking at, trialling, and testing.

Indeed, various parts of the British Army have been looking at different trailers and carts, from the simple to the costly, fantastic, how can we know if they are of any use if we don’t try them, how can we understand how to use what is just one tool among many if we don’t learn?

There are constraining dimensions and weights to consider.

Payload targets will be dependent on configuration.

In the handcart configuration, 200 kg would be the target, the same as the stretcher carrier.

When used for a quad bike ATV trailer, there are other factors to consider beyond the desired payload.

There is some relevant UK legislation for trailers, mainly that they have to have a braking system if the total weight exceeds 750 kg.

Larger quad bike ATVs tend to average at about 600 kg max towing weight and tongue weight, and the in-service Yamaha Grizzly 450s have a maximum towing weight of 600 kg. It seems inevitable that they will eventually be replaced, although the newer Yamaha Kodiak 450 retains the same 600 kg towing capacity, as other comparable models from manufacturers.

The in-service SMT 172B ATV trailer has an unladen weight of 243 kg, with a maximum gross weight of 450 kg (207 kg payload) at 60kph, but this is reduced when carrying a stretcher to 40kph, although the gross towing weight is increased to 600 kg or 407 kg payload.

Reduce the unladen weight whilst retaining the gross weight limit of 600 kg.

For airborne forces, it will also need to fit within the weight and dimensional constraints of a double CDS pallet so it can be easily air dropped without needing a special air despatch platform other infantry do not necessarily need to worry about this constraint.

Skis and pontoons or flotation bags might be useful for some, not others.

The difference I have proposed above is not in design (how many variations of a load bed with two wheels are there) but in how they are delivered to the Field Army.

There is a metric tonne of design variations, wheels outboard or underneath, different wheels for different surfaces, frame, and box or frame and sheet material, a thousand different ways of securing loads, and one wheel or four.

And different applications, a carrier for an Easibridge or NLAW, a water bowser or stretcher.

There is a richness in the requirements that can only realistically be explored by using a kit of parts, and those parts are widely available from a vast array of retailers and manufacturers.

I’m quite in favour of using pallet boxes, but I bet you knew I was going to say that!

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

A very comprehensive dive into options. It could be the start of an interesting competition at the Royal Tournament.

Deep dive into all things unsexy but very important.

Investment into ideas and suitable equipment in this area makes me thing of marginal gains instead of the silver bullet always being sought.

Nice work TD but where are the pallets and shipping containers?

If army workshops don't have sewing machines, how do you fix it if someone's bergen or webbing fails?

Just a thought, would there be any military use for wheelie bags meant for shopping? Even a regular one can hold 20-25kg – that feels like nothing until you have to go uphill, and even then is far easier than just carrying the same weight. Never tried to pull one on rough ground though, beyond getting it up onto a kerb.

HughN, once when I was in school they made the mistake of leaving a hand truck in the sixth form common room. We had one person stand on it, another push it, then raced it around a slalom we made out of chairs…

Needs a modular power unit, as on mexiflote…

https://news.sky.com/video/square-video-motorised-wheelbarrow-11987858