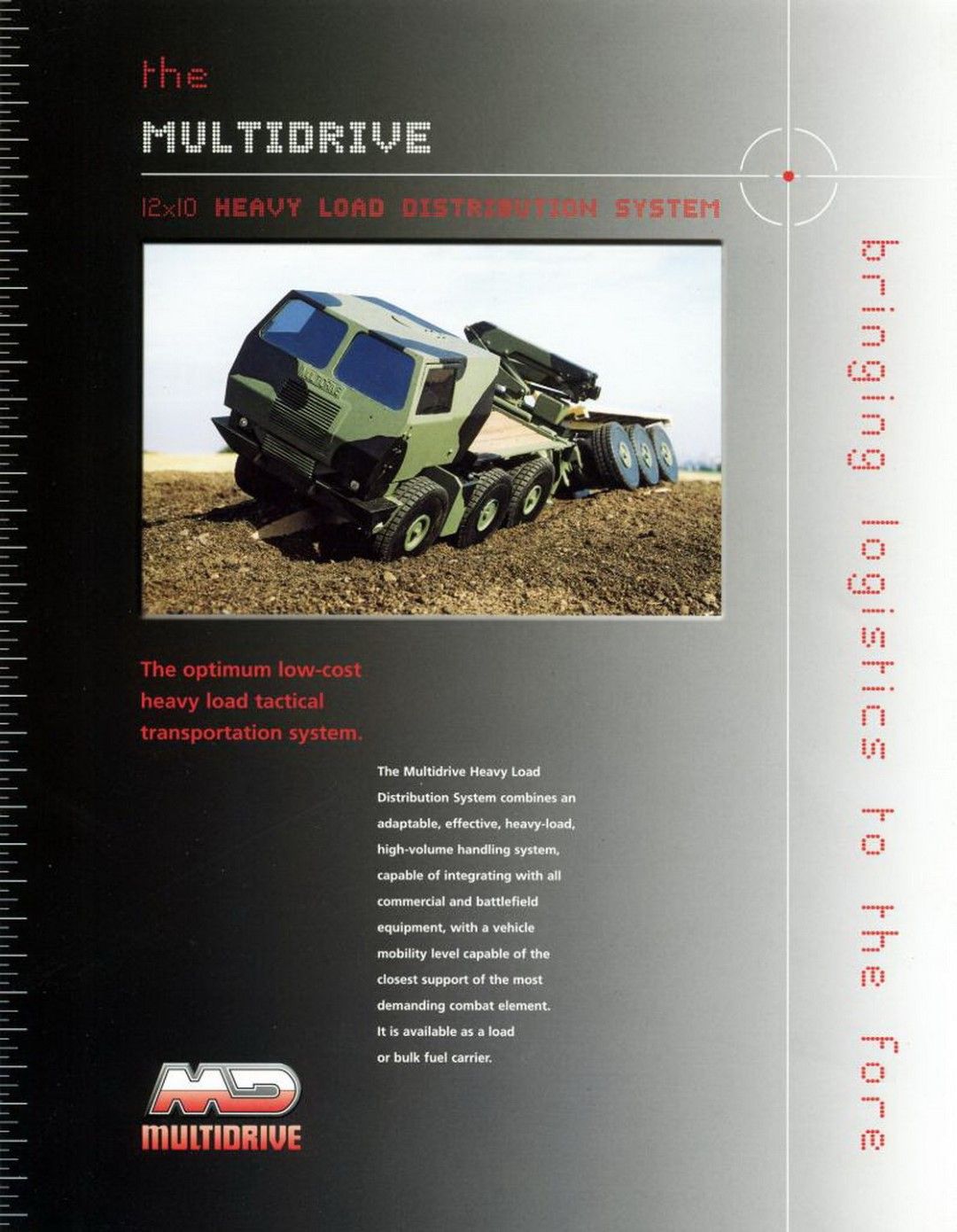

Multidrive Vehicles have a complex and multi-faceted history, but it is a fascinating history nonetheless.

From a UK defence perspective, they designed and produced several innovative products that many think were lost opportunities for the British Army and defence exports.

David J. Brown CBE established DJB Design and Engineering in the mid-seventies to design and build vehicles. Merging with Artix in 1983, Multidrive was formed. Bedford Truck was purchased from General Motors in 1987, renaming it to AWD Bedford, reflecting the all-wheel design direction.

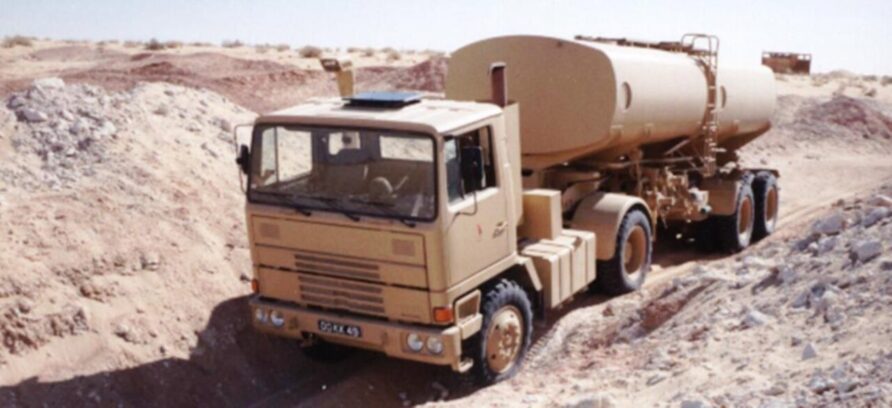

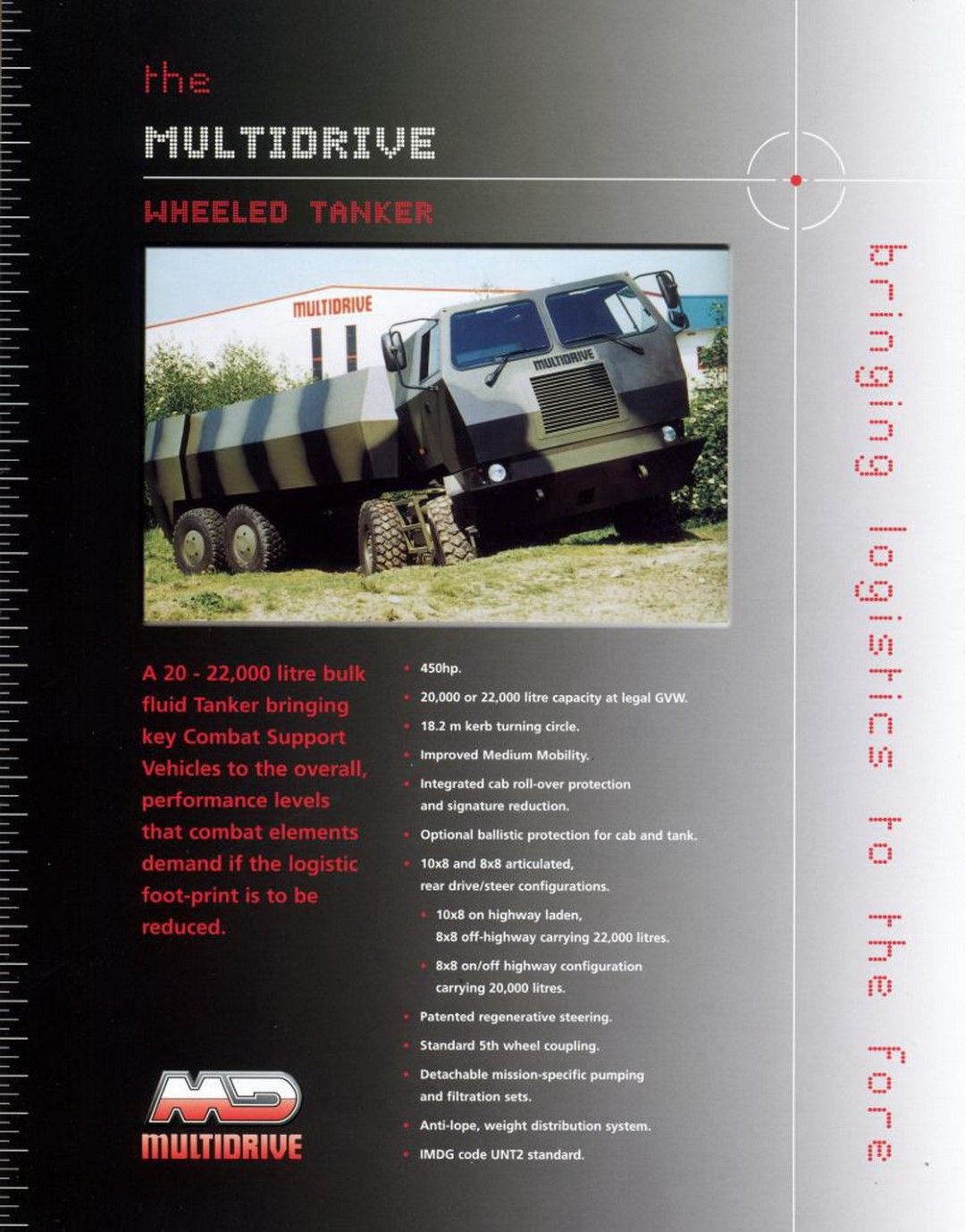

Multidrive Fuel and Water Tanker

The first defence use of the Multidrive powered trailer concept was for fuel tankers for use in Operation GRANBY, the liberation of Kuwait.

The MoD purchased 26 fuel and water tank vehicles, based on Bedford AWD tractor units.

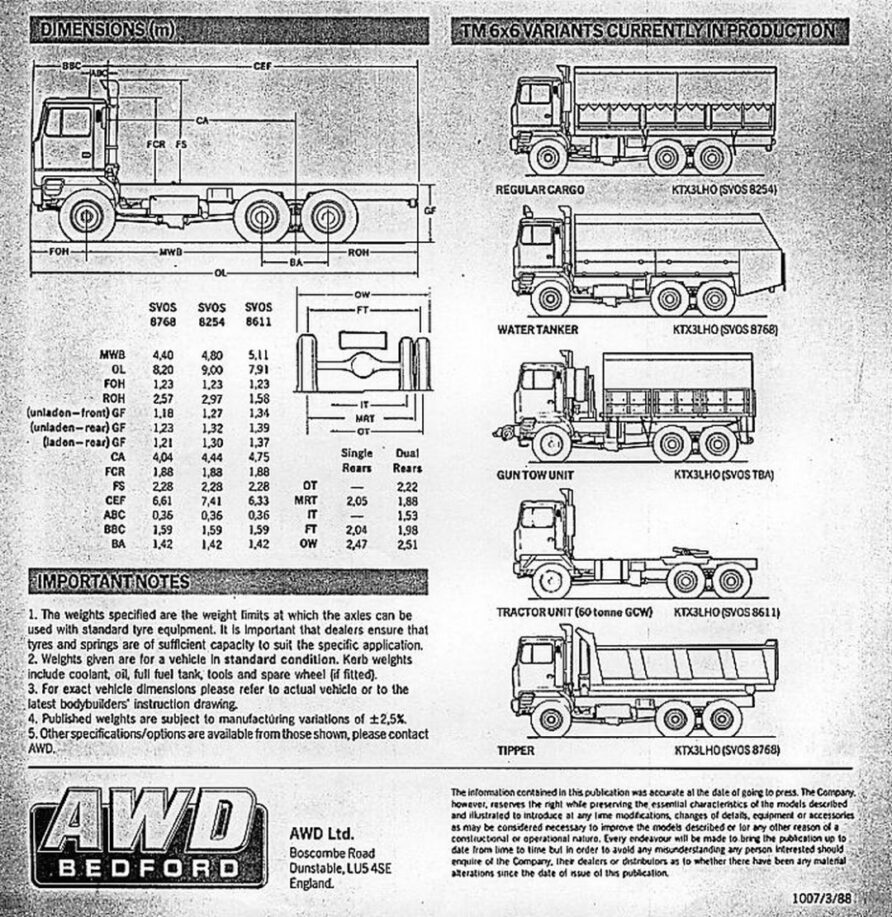

The AWD brand continued with Bedford trucks.

The TL and TM range were purchased by the British Army, but in 1992 the company went into receivership and then purchased by Marshall’s of Cambridge.

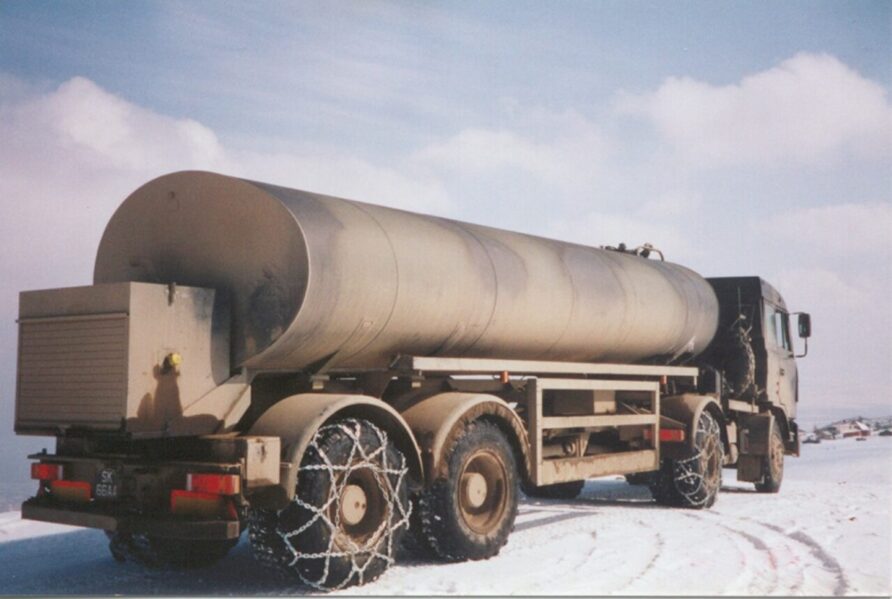

Combining the experience of dealing with the MoD through AWD and high mobility on road conversions from Multidrive an urgent operational requirement for the Army was rapidly fulfilled for operations in the Balkans, first Bosnia and then later, for Kosovo.

Both used Foden tractor units.

The 8×6 ‘Improved Mobility’ tanker trailer could hold 20,000 litres of fuel or water with the ability to discharge from the left or right. Using the powered trailer and rear-wheel steering, it was highly mobile, having a 17m turning circle, for example.

Other advantages were reported to be improved tire scrub, low chassis stress and increased safety, especially on gradients.

For the Kosovo deployment, the fuel tanker was joined by a water tanker variant that incorporated a heating system to prevent the water from freezing.

They were also subsequently used in Iraq and Afghanistan.

All three deployments demonstrated the value of the concept, the vehicles were highly mobile, low-cost, safe, and reliable.

Multidrive Vehicle Transporter

Although none were formally introduced, the British Army and Multidrive designed and trialled a flat-bed version for transporting smaller vehicles, like the CVR(T) shown in the image below.

Also proven, was the ability to adapt MOTS/COTS tractor units, both Foden and Bedford.

This image illustrates perfectly the propshaft arrangement for the powered trailer.

Future Cargo Vehicle

In 1996, much of the group was sold to Caterpillar and David Brown became a design consultant to Caterpillar on the Series 7 articulated dump truck, still being made at Peterlee in County Durham.

With a singular focus on designing and building vehicles for defence and industry, Multidrive moved to a new facility in Thirsk, Yorkshire.

The Future Cargo Vehicle (FCV) and Future Wheeled Recovery Vehicle (FWRV) projects afforded Multidrive an opportunity to win a much larger contract with the MoD than the fuel and water tankers.

Future Fuel Vehicle (FFV) was advertised as a PFI in January 1998, with Future Cargo Vehicle (FCV) following in August 1998 and Future Wheeled Recovery Vehicle (FWRV) in September 1999.

FFV and FCV went through a pre-qualification phase to select a shortlist of potential bidders who would be invited to submit outline proposals. There were three endorsed staff requirements for the trucks;

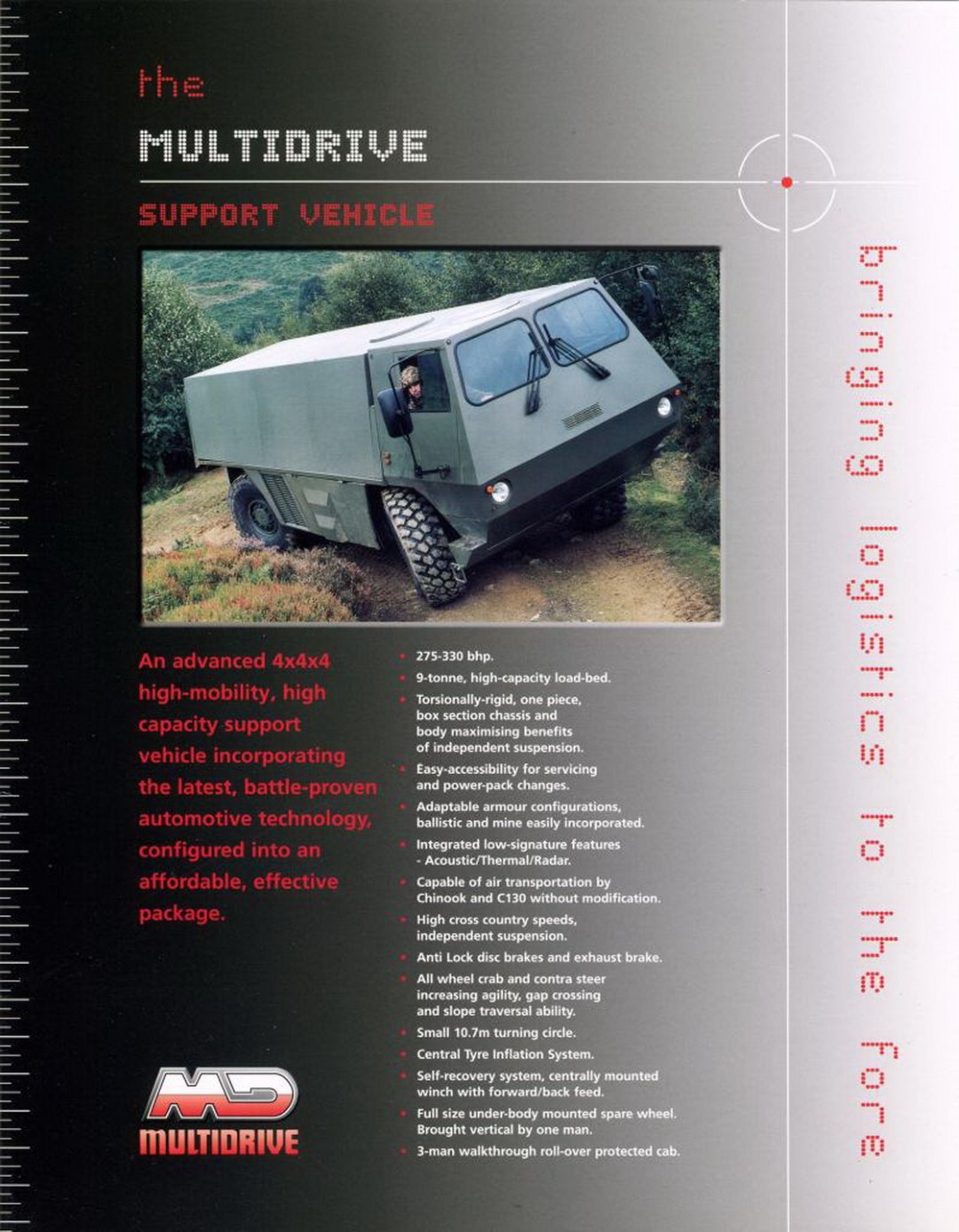

- SR (SLA) 4100 for a 6-tonne truck, High Mobility (HM)

- SR (SLA)4096 for a 9-tonne truck, Intermediate Medium Mobility (IMM)

- SR (SLA) 4120 for a 15-tonne truck, Medium Mobility (MM)

Multidrive responded with a highly versatile concept that started from a clean sheet design, producing a number of articulated and non-articulated prototypes between 2000 and 2001.

Around this period, the USA also had a similar set of requirements and in 2002 Multidrive was awarded a 6-vehicle demonstration contract with the National Automotive Center.

Feedback was reportedly excellent.

The feedback from the NAC is that the US military is thrilled by it, it’s like an answer to a maiden’s prayer. We hope it will lead to our direct involvement in the provision of trucks to the US army.

Chris Chambers, Sales and Marketing Manager

A decision was taken in 2001 to change the direction of the procurement model and, instead of the planned PFI, procure the vehicles under a conventional arrangement, using an international competition.

The subsequently renamed Multidrive Multi-Purpose Mobility Platform (MPMP) was then formally submitted for the Future Cargo Vehicle (FCV) requirement.

Multidrive Multi-Purpose Mobility Platform (MPMP) Features

Suspension and Steering

The independent active suspension system was designed by Davis Technologies and Arvin Meritor.

Coil-over shock absorber units were replaced with Davis struts that reduced the weight by half.

They had automatic and manual modes, including dynamic ride height and tilt and kneel functionality for cargo loading/unloading and tire changing.

All-wheel steering (both crab and contra) provided excellent manoeuvrability and a small turning circle of 9.7m, it also had a central tire pressure system.

Payload and Mobility

The base 4×4 vehicle was defined as High Mobility, with a 6-tonne payload.

Adding another 3 tonnes onto the same vehicle, for a payload of 9 tonnes, simply degraded the mobility to the slightly less ‘Improved Medium Mobility’ category.

The same vehicle could therefore be used for both the 6 and 9-tonne payload requirements.

Protection and Cab Design

Although the base vehicle had no protection, it was designed to accept appliqué armour to improve ballistic and mine protection.

Reduced acoustic was integral to the design, and the sloping sides were designed to reduce radar signature

The cab could accommodate 3 personnel and be of a walk-through design.

Transportability

With a payload of 6 tonnes, the MPMP was still able to be underslung by a Chinook and was easily carried by a C-130.

Maintainability

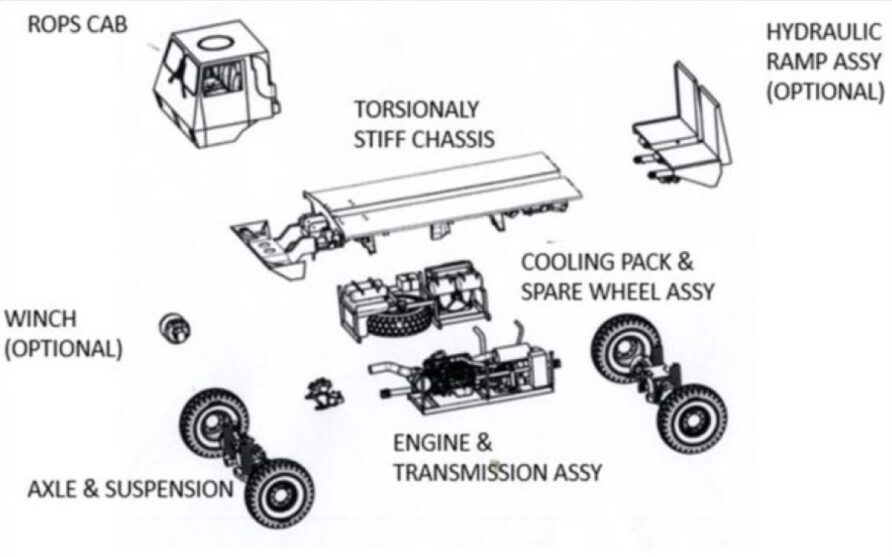

Instead of a traditional ladder chassis, the MPMP featured a torsional stiff spine underneath, which was mounted on two slide-out modular trays.

One module housed the 275bhp Cummins diesel engine and transmission whilst the other, housed a fuel tank, cooling pack and spare wheel.

The spare wheel module featured a slide-out and ‘make vertical’ assembly that could be operated by one person.

Pulse Propulsion Load System

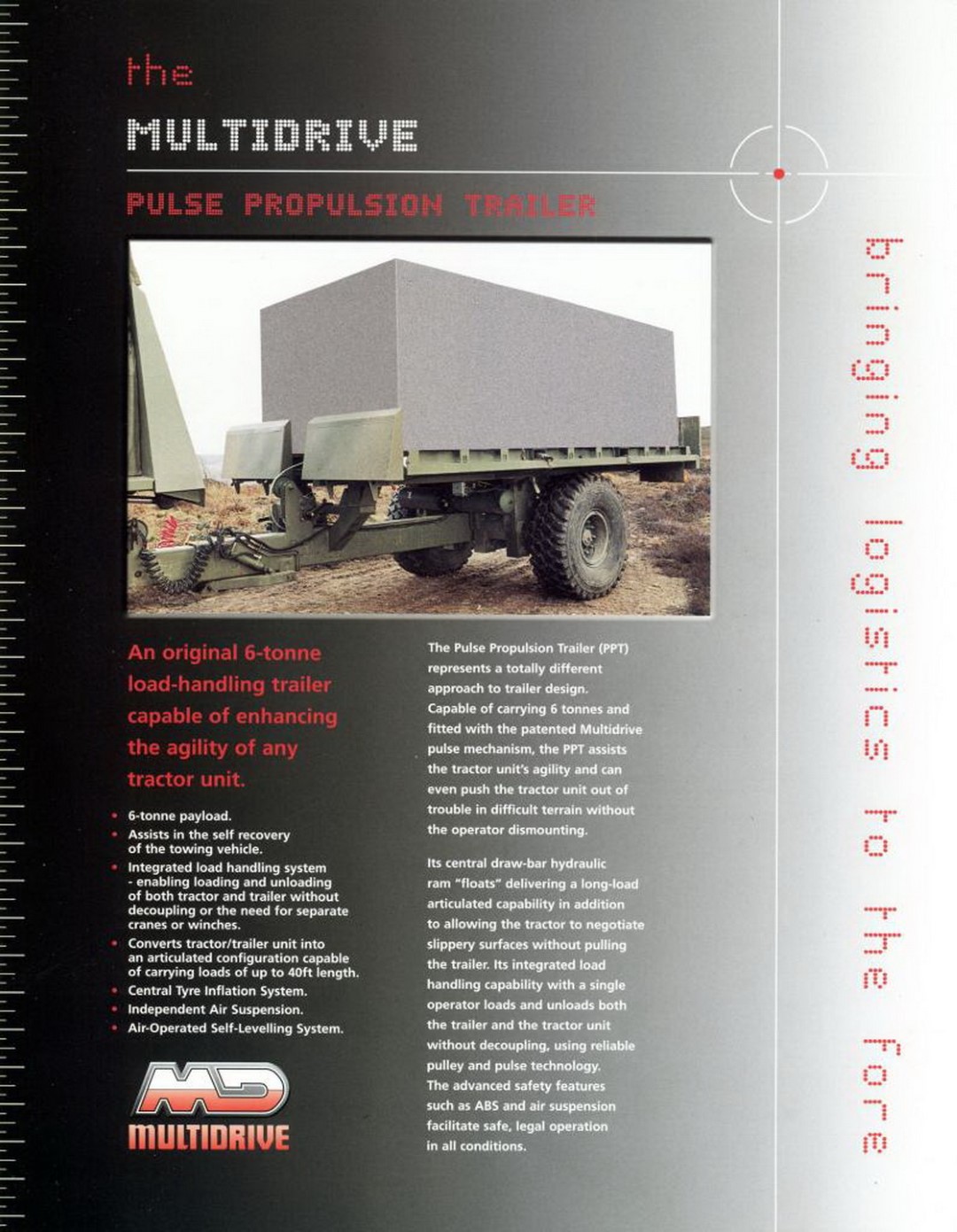

The integrated trailer was integral to the concept, designed to allow the same basic vehicle to meet the 15-tonne requirement, in addition to the 6 and 9-tonne requirements.

This approach was unique, using the same vehicle for all three requirements would provide significant logistics commonality benefits.

Not only was it powered, but it had central tire inflation, and self-levelling and was articulated in a manner that meant mobility did not suffer.

This allowed the payload to be increased to 15 tonnes whilst maintaining a turning radius of 10.7 metres.

The self-loading system was designed with both pallets and ISO containers in mind, and the self-unloading feature was also capable of meeting the DROPS requirement for artillery ammunition pallets.

Extending the trailer allowed longer loads to be carried and this feature was also used for self-recovery.

With the Pulse trailer, two 20ft (6.1 m) ISO containers could be transported, and for one-quarter of the cost of the 6-tonne base vehicle, the same payload as that vehicle could be carried.

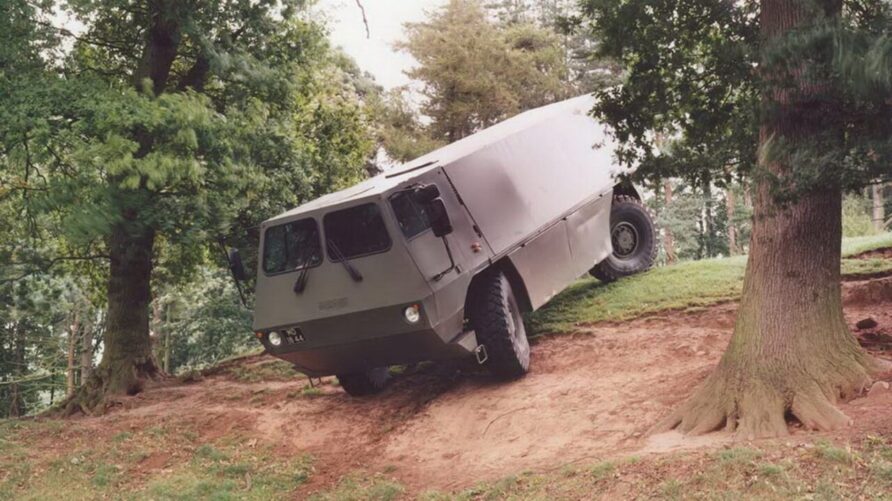

Multidrive Flex Frame

Although the MPMP was of undoubted capability and had several unique innovations, it did represent some risk as the Army was considering the replacement for the venerable Foden, Scammel, Bedford and DAF trucks.

A more conventional truck layout (engine forward) called the FF88 was also developed that used an articulating and hydraulically actuated trailer mechanism called the Flex Frame, the frame also carried a prop shaft to carry power to the trailer’s wheels.

The advantage of this system was it allowed the vehicle to maintain powered contact with the ground over undulating terrain, with 50 degrees up/down and 50 degrees side to side movement.

Rotation was a full 360 degrees (although it is difficult to imagine this being exploited in use).

Both tanker and cargo (with hydraulic jib) variants of the Multidrive Flex Frame were produced.

Video

This design was also proposed for the Wheeled Tanker requirement

Note the shaping of the tanker to reduce visual and radar signature.

And Heavy Equipment Transporter (HET)

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Stewart and Stevenson

Such a large order might represent a financial bridge too far for Multidrive, so they partnered with Stewart and Stevenson for the Support Vehicle and associated projects, replacing the Future Cargo Vehicle.

The Family of Medium Tactical Vehicles (FMTV) was produced by Stewart and Stevenson, with production starting in 1991. This was a huge order, with approximately 70,000 built to date.

Although Stewart and Stevenson are now owned by Oshkosh, at the time, they partnered with Multidrive (and LEX and LDV) in competition with Oshkosh. MAN ERF and Daimler Chrysler.

With Multidrive providing the powered trailer technology and Stewart and Stevenson providing the well-proven and conventional tractor truck, the FMTV Flex Frame concept was developed.

This allowed the advantages of the Multidrive system to be exploited by both a more conventional tractor unit and a larger company.

As we know, MAN eventually won the SV contract, and Oshkosh, the tanker and heavy equipment transporter contracts.

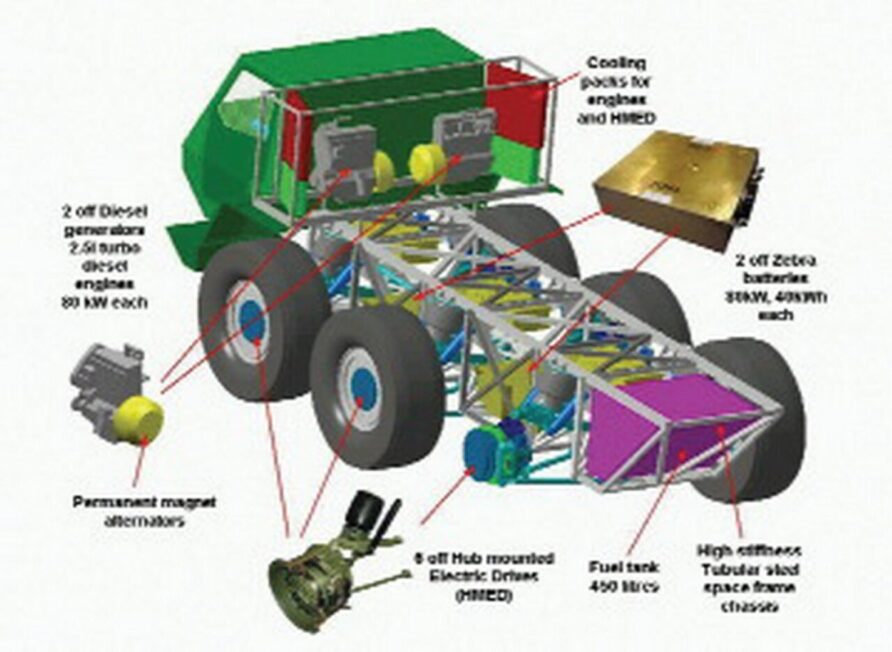

DERA High Mobility Demonstrator and QinetiQ Hybrid Drive Demonstrator

The Defence Evaluation and Research Establishment (DERA) partnered with Multidrive for the High Mobility Demonstrator (HMD) in 1996, a concept of a 6×6 high mobility vehicle using a Cummins 6-cylinder engine that used a half-size DROPS rack.

When DERA became QinetiQ, Multidrive again partnered with them on the Hybrid Electric Drive (HED) demonstrator vehicle.

Under the Applied Research Programme (ARP) contract, QinetiQ was to act as a systems integrator for the design and build of a 6-wheel, 18-tonne technology demonstrator, with individual wheel control.

The 2006 demonstrator also included input from Magnetic Systems Technology and BAE Systems Land Systems.

Welcoming the new contract, Defence Procurement Minister, Lord Bach said;

Building a hybrid drive demonstrator will allow us to closely study the claimed advantages of hybrid electric drive (HED) and its suitability for future military vehicles. The results of this wholly MOD funded evaluation programme will provide detailed data in key areas such as mobility, design flexibility, operating costs and fuel economy, which will lead to informed choices based on hard data and real experience.

QinetiQ has since gone on to secure a number of research and development contracts with hybrid electric drive systems.

Then and Now

In 2004, David Brown was tragically killed in a car accident and in the same year, the MoD awarded the Specialist Vehicle contract to MAN.

The company would not recover from these twin blows and was eventually put up for sale in 2006.

Details seem to be vague, but I think the company went two ways, based on the business divisions within the Multidrive group.

The Kelland Group (now McConnell) purchased the Multidrive agriculture business, and a private buyer (Dr Qu Li) the defence and mining business.

Kelland continued to develop the Multidrive tractor, including a forward control cab version and one with an additional axle.

Production of this design ceased in 2023 and now, McConnell only markets the Agribuggy 2, used as a sprayer and spreader.

Multidrive still exists today and continues to develop and market the M8 Series, an industrial trailer, and a horizontal ejector system for mining and construction.

Read more at the Multidrive website.

http://www.multidrivevehicles.com

The same owner is also re-launching the Morris Commercial brand on the same site in Evesham.

Multidrive technology, I think, represented a real opportunity lost for the British Army, a real shame, like so many others.

Change Status

| Change Date | Change Record |

| 24/12/2016 | Initial issue |

| 22/07/2021 | Minor update and format change |

| 29/08/2023 | Update and new images |

Discover more from Think Defence

Subscribe to get the latest posts sent to your email.

What are the main advantages of multi-drive? Is it primarily AWD for trailer loads?

It puts more of the weight the weight over driven wheels, distributes that weight over a longer track and because it articulates, driven wheels tend to stay in contact with the ground for longer over uneven terrain. The pulse trailer could also be used to push the tractor forward, thus aiding self recovery and the turning circle for a long load is incredible.

What a great piece on great British innovation and a lost chance indeed !

Thanks TD, fascinating read! The Multidrive/pulse trailer combination looks like a really useful bit of engineering. Presumably it lost out on the grounds of cost or risk?

US Marine Corps has similar requirements to that of the UK Army. But the final result seems both less ‘mountain-goat’ agile, and technically more specialized, including fully-independent suspension all around, than the multi-Drive approach. USMC went for the 10×10 (=5 powered axles) Logistics Vehicle System Replacement (LVSR). See also https://en.wikipedia.org/wiki/Oshkosh_Logistic_Vehicle_System_Replacement_(LVSR)

Over 2000 vehicles have been built.

The 3-axle trailers are non-powered.

Is the Viking or Warthog not classed as a multi-drive vehicle?

To turn around on forestry roads would sure be more difficult than with MAN SX. The use of multi-axle trailers is restricted to ‘rear’ support services in land forces for a reason.

One COULD make a multi-axis trailer agile with a backward driving camera and individually powered/braked if nto even steerable wheels on the trailer (with driver in the cabin steering via monitor and sidestick when driving backwards), but that’s more complicated than to use a 15 ton 8×8.

All these solutions appear to be direct drive from the tractor, has any work been done on hydraulic or electric powered trailers?

GAB

It is worth noting that in modern articulated buses the engine and transmission lie in the rear unit and effectively push the unpowered cab unit along.

The British Army has always had a relucatnce to embrace multi-drive vehicles. I worled for SMC Engineering in the 80s and we developed the Peretie 6×6 land Rover for Australia which beat the Unimog in the Trials. It should have been a joint UK-Austalian Project but in their wisdom the British Army rejected it on en engine grounds as they wanted a diesel. They bought the disastrous RB44 which cost milllions to upgrade and never worked to pacify Boughton and david Stride which lost the Multilift order to the Finns.. SMC also developed a forward control 6×6, the largest Land Rover in the world! The Multidive concept was brilliant and saved many lives in Kosovo as the 6×4 tankers were pushing themselves off road into ravines. Another lost opportunity!

It's always been missed opportunity for the British Army, some innovation comes along which could benefit the forces some ' penpusher in Whitehall' say no . Saying that I'm surprised that the tank (1914-1918) made it past them!