This post examines options for further exploitation of the Container Delivery System (CDS), expanding its applicability to light vehicles, engineering plant, and weapon systems.

Joint Doctrine Note 1/20 describes two categories of Air Manoeuvre, airland, and airdrop, the latter being defined as…

Airdrop is the delivery of personnel or cargo from aircraft in flight. Personnel and equipment can be dropped separately or together at varying altitudes determined by threat. In contrast to airland, airdropping personnel and equipment negates the requirement for an airfield, but it does require the force to assemble on landing

Airborne forces will be dependent on air despatch to deliver anything not carried until a landing site is available.

Airdropping of supplies will be conducted in several scenarios.

- As a component of an airborne operation

- Supporting Humanitarian Assistance Disaster Response (HADR) activities

- Special Forces support

Personnel and small equipment bundles can use the aircraft side doors but the majority of bulk stores in an airborne operation use a technique called Container Delivery System (CDS).

This same technique is often used to provide humanitarian supplies.

What is the Container Delivery System (CDS)

Almost all western cargo aircraft and helicopters with a rear ramp are configured to use CDS.

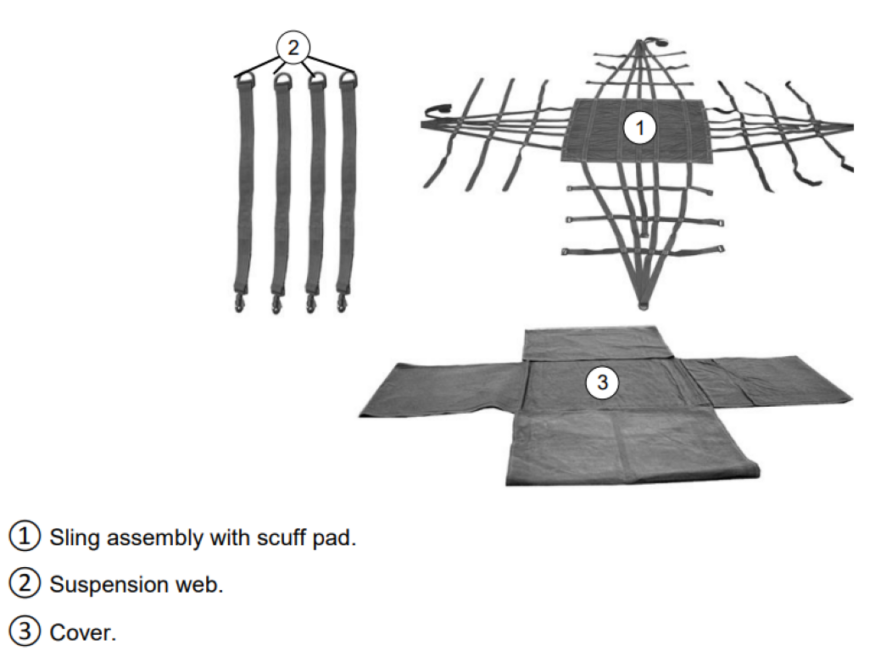

There is a lot of engineering and hard-won applied technique with CDS, well beyond the scope of this article, but briefly, it comprises three main components, the container subsystem, the main recovery subsystem (parachute), and the extraction/ejection subsystem.

Individual items are secured in cargo bags, drums, or other containers, the image below shows an A-22 Bag Assembly.

These are then rigged to a plywood base (skid board) so that the whole assembly can be handled as a unit load. Energy-dissipating materials such as closed-cell foam and honeycomb cardboard are used to protect the load from landing forces.

A parachute is secured to the top, which upon exit from the aircraft using gravity, is deployed by a static line.

Despite individual stores’ weight distribution being balanced by the rigging team, there is no guarantee the load won’t end up upside down on its side, complicating recovery.

Recovery can be by hand, breaking the container down into individual loads, or using some mechanical means such as a crane or pallet lifter.

Because of its US origins, all dimensions are in inches, a Centreline Vertical Restraint System (CVRS) creates two rows on the aircraft cargo floor, each row 48″ wide.

48″ is the primary constraining dimension, and even modern aircraft like the A400M use the same.

The length can vary in length depending on the load but in most instances, it is also 48″

To accommodate longer stores, a 96″ long base can be used.

The same double-length skid-board can also be used for small vehicles such as quad bike ATVs

The maximum height is 83″ unless a specific rigging scheme is approved.

It should also be noted that the skid board needs some clearance space for rigging so although the outer dimension is 48″ wide, in practice, this means any load has to be a little less.

The video below shows the RAF testing the A400M with a large payload that appears to be twenty-four CDS pallets for a total load of 23 tonnes.

A Problem Statement

Larger vehicles and equipment use wider and considerably sturdier air despatch platforms, as shown below.

And that right there is the problem.

We have the vehicles, we have the aircraft, but we don’t have any air despatch platforms that are cleared for either.

The withdrawal of the C-130 has left 16 Air Assault Brigade without the ability to parachute anything more than some rugged folks and several pallets and quad bikes.

No artillery, no engineering plant, no vehicles.

I am sure we will eventually find funding for heavy air despatch platforms for A400M and C-17, but until then, we have CDS.

Nothing else.

JDN 1/20 reminds us that space is limited and vehicles must be flexible.

Vehicles must be versatile to move quickly between tasks, for example, powering command posts, then pooled to move the mortar line within range of the objective and dump supplies for fires support groups; during the attack they will resupply and evacuate casualties.

It also describes the importance of Airfield Damage Repair

To guarantee joint theatre entry at a point of our choosing, air manoeuvre forces must have a viable airfield or create a temporary alternative. Repairing and sustaining runways is vital to mission success and air manoeuvre combat engineer specialists provide one of the most important joint theatre entry capabilities in ultra-lightweight airfield damage repair. They can repair an existing runway by airdropping parachute-trained personnel, airfield damage repair equipment and materiel. After the assault, they can airland more (often heavier) equipment and materiel to maintain or enhance the runway and airfield fixed- and rotary-wing aircraft

The challenge is to find military useful equipment that weighs no more than a tonne and can fit inside the footprint of an 8×4 sheet of plywood you could go and buy from a DIY store.

Where possible, it should be available as either military or civilian off-the-shelf, or with minimum modification.

I am going to structure the rest of this article as a set of ‘things to consider’

Better Exploit Quad Bike ATVs

We already have quad bike ATVs in service, cleared for air despatch using CDS.

Could their utility and versatility be improved?

Instead of lashing stores to racks with bungee cords and webbing straps, a more design-led approach might exploit modular systems like Rotopax fuel and water containers.

Or Molle panels.

Other storage boxes, racks, and load bed extenders are readily available.

At just under eight hundred Pounds, the Quadcrate Butterfly front and rear racks fold out to secure longer items, mortar barrels, telescopic masts or NLAW.

And for those that work with military working dogs…

The same company also makes a barbed wire dispenser that fits the back of the vehicle.

LV-TEH in Latvia makes a similar range of storage racks.

Building industry modular storage containers like the Milwaukee Packout with compatible mounting racks are being increasingly used by outdoor enthusiasts.

The Estonian Iron Baltic ‘mini motion’ package turns a quad into a light-duty bulldozer.

Atlok in Finland offer a similar system but with different blade and bucket options.

A power broom can be fitted, making use of a standalone engine, useful for clearing small debris from runways.

Flail mowers, stump grinders and soil stabilisation solution sprayers might find some applicability in niche runway clearance and development roles, all available for ATVs.

Wild Hare Manufacturing in the US makes a system that turns an ATV into a lightweight loader, with a bucket or pallet forks.

None of these would be permanently attached, needing to be assembled on the ground, and would take up their space in a double CDS position on an aircraft.

Are these going to dig an AS90 pit, no, of course not.

But in the spirit of finding versatility with what we have, and doing things even marginally quicker than with hand tools, they could be considered.

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

The Department of Better Trailers

The in-service Logic SMT 171/172 trailers are quite well-developed.

They have many features specifically for military use such as fold-down brackets for short gap crossing ramps, fold-up hitch and mountings for a single stretcher.

Their 150 kg max payload is quite low and the stepped body design (to keep their width the same as the quad bike) means the width at the bottom is small, not optimised for pallets or larger loads.

Longer and higher capacity trailers are available, single or twin axle, aluminium or MDPE body, tipping or fixed, wheels inboard or out.

Using a flatbed design with demountable side rails as shown below would allow them to be rigged two per 96″ CDS, and the model shown, if designed with a sliding or demountable hitch arm, would be small enough to fit inside the single 48″ CDS footprint or four per double.

Low-density loads like Bergen’s could be secured using tie-down points and cargo net, or with the addition of demountable side rails.

Simple things like having welded lashing rings at convenient locations can create a tangible improvement, even better with a cargo restraint system like Koller Defence supply.

Although the image below shows a simple flatbed trailer that is 4″ too wide for CDS, one imagines it would be a relatively simple engineering change to make it smaller. A twin-axle flatbed could be used for larger and heavier loads than the Logic trailers, and with a simple load bed, also rigged two high.

The LV-TEH Combat Support Platform is approximately 200 mm too wide, again, the concept is similar.

With a set of ramps, these could also be used to transport some engineering plant described below.

A similar design is shown below in a dedicated stretcher carrier version.

As all Think Defence readers know, there is a world of trailers out there, including one that can even be turned into a boat (although this particular design is four inches too wide for CDS)

With higher-density stores like ammunition, it would be relatively easy to max out on the typical maximum 700 kg payload of larger trailers, but even accounting for the weight of the trailer, it would still be within the 1 tonne maximum CDS payload. Whether an in-service quad bike ATV could tow a 1-tonne trailer is also questionable.

All that said, six quad bikes and six trailers, with a total payload of 4,200 kg, are perfectly possible for a single A400M flight. That is roughly 420 81 mm mortar bombs (assuming all packaging is generally the same weight as the bomb).

Although going somewhat against the principle of everything having multiple uses, the ATR Trailer from All Terrain Res-Q in the US does look effective.

The trailer folds for easy transport, so could be optimised for CDS compatibility.

Although not strictly a trailer, LV-TEH in Latvia (as above) also makes a folding rack that can be used to secure a casualty, although not sure how well!

Pallets and Pallet Trailers

Traditional pallets tend to be less of a concern for air despatch, they are unlikely to be handled as a unit load when on the ground, with CDS packages always weight and space optimised by the riggers.

Most standard pallets are also dimensionally incompatible or inefficient with the CDS dimensional constraints, especially the need to leave space for securing straps to the skid board. NATO or Euro pallets, at 1.2m, just don’t fit.

1mx1m pallets are available and fit quite well with a CDS skid board, but less commonly available. 1.1×1.1m plastic pallets are also available, so if pallets were required, these less standard sizes would be used.

But unless the force on the ground has some means of handling the pallet as a pallet, they are just dead weight.

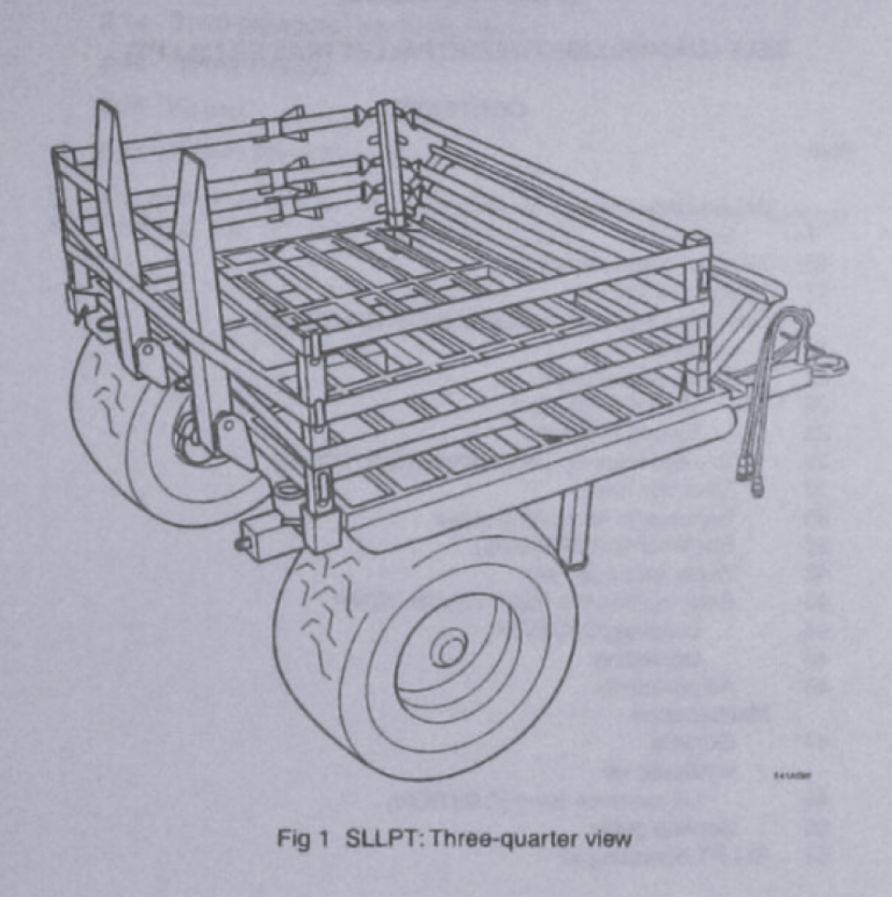

When British Army airborne forces were better resourced and could airdrop larger vehicles like the Supacat ATMP, it was able to move ammunition pallets (especially those for the 105 mm Light Gun) off a landing site using dedicated pallet trailers.

To increase carrying capacity and flexibility, a pair of specially developed trailers were also introduced…

- FLPT (Fork Lift Pallet Trailer)

- SLLPT (Self-Loading Lightweight Pallet Trailer).

Although there are many variations, the basic trailer had a hydraulic tipping mechanism and pallet forks.

The driver would simply tilt the trailer into the down position, reverse onto the pallet, tilt the trailer back up, and drive away.

The maximum payload for the ‘flipit’ trailer was 1,400kg, and it could also be converted to carry three stretchers.

Demountable corner posts could also be used to form sides for loose loads, with ratchet straps used to secure the load.

A 910 Litre Water Carriage Pack (WCP) was also available.

The conversion took only a few minutes and the posts were carried on the trailer.

I don’t want this post to be a nostalgic pity party, we have to work within today’s reality, and those pallet trailers would be too wide in any case, and no one makes them either.

A similar concept is found in the fruit industry, the orchard bin and the roller trailer.

They use standard-sized wooden or plastic pallet bins and load them onto the trailer by reversing, once secured the vehicle drives away.

Other variations use chain drivers and rollers, or tilting load beds, but the overall concept is the same.

None of the solutions above would be ready to go now, each would need to be re-engineered to fit the specific CDS constraints.

It would also be possible to approach this from a single-pallet or double-pallet perspective.

Pallet boxes 1m wide and 2.16m long would fit perfectly inside the double CDS footprint.

They are available with lids, drain plugs, dividers and in various colours (thankfully).

The pallet box could simply be attached to a flatbed or roller trailer and used as a conventional trailer, or they could be demounted like a small version of a DROP/EPLS flat rack.

Although every item of stores or equipment inside the pallet box could be carried by hand, specific unit loads could be defined, packing schemes developed, and subdividers and energy-absorbing materials CNC cut.

For example, a mortar platoon could have all their equipment and an initial allocation of mortar bombs pre-packed inside the container, ready to be cleared in one go from the landing site.

I also looked at using Joint Modular Intermodal Containers (JMIC) for this, but they are too wide.

Alternatives to Quads and Trailers

Within the constraints of CDS dimensions, it is pretty difficult to beat the quad bike ATV and trailer combination for clearing landing sites, providing mobility for small teams, and taking some load off the soldiers’ backs.

They are in service now, well-proven and effective, and exist in a commercial and military product ecosystem that can be quickly and easily exploited if and when funding allows.

If there is an objective in looking at alternatives, it is simply to increase that single A400M lift of six quad bikes, six trailers, and four or five tonnes of stores that can be moved by them both.

Two-Wheel Tractor

Bear with me on this.

The walking, or two-wheel tractor, is not a common sight in the UK, but they are quite common elsewhere.

This is what 5.6 tonnes of rice looks like, an incredible payload for such a small unit, although I doubt it will be winning any speed trials any time soon.

This is the point of two-wheel tractors, they are not fast, but they are incredibly cheap and built for shifting weights. Many will have a Power Take Off for implements and reversible handlebars to enable pushing or pulling. The more sophisticated models also include options for remote control and battery power.

In our use case, every cubic metre counts and if we can use that engine and PTO for other things (see later in the post), we are maximising volumetric efficiency, however silly a Para might feel riding one.

They can be purchased from a number of UK, US and European manufacturers, one does not need to go too far to find them. Example manufacturers include Casarzo, Koeppl, Lampacrescia, Bertolina, BCS, Grillo, Ginko, Rapid Tractors and Barbieri

Maximum speed tends to be no more than 10-15kph, some are available with zero-turn electronic steering and in power ranges between 8hp and 40hp, diesel or petrol. Weights typically range from 150 kg to 250 kg.

Below is an example from BCS, their largest model, the 570 mm wide 780 HY Stargate, as can be seen, the handlebars have a wide degree of articulation.

By removing the tiller attachment, and angling the handlebars, four can be accommodated on a double CDS skid board. Smaller models are available, but I wanted to use this as an example of how a quad bike alternative, whilst much slower, can provide a sensible option when space is constrained.

In the single A400M, instead of six quad bikes and six trailers (each with 700 kg payload), we can now have eight tractor units and 8 trailers, plus an additional four single CDS pallets.

5,600 kg plus 4,000 kg, about double that of using quad bikes.

Now obviously, mobility will not be as great, and speed certainly won’t be, but this is the nature of trading payload for speed.

This also makes the same assumption of 700 kg payload per trailer as with quad bikes.

Unlike quad bike ATV trailers, two-wheel tractors require a seat, but again, there is a wide range of manufacturers that can provide an equally wide range of trailer options, the one below costs six hundred quid.

Unlike quad bike ATVs, two-wheel tractors generally have a Power Take Off (PTO) which means a powered trailer (the one below is from Errepi and is too wide for CDS, but it would not be a huge challenge to create one slightly smaller) can be used to create a 4×4 system.

Driven axle trailers are common in agriculture, and the old Land Rover 101 Forward Controls vehicles even had one.

Need more grip, you can get crawler track units for them from Agrrizeta in Italy.

Two-wheel tractors are hardly a statement of war, they are slow and can be noisy, but in a single A400M drop, they can double the amount of stores available to the deployed force whilst still maintaining a measure of mobility.

Fresia F-18

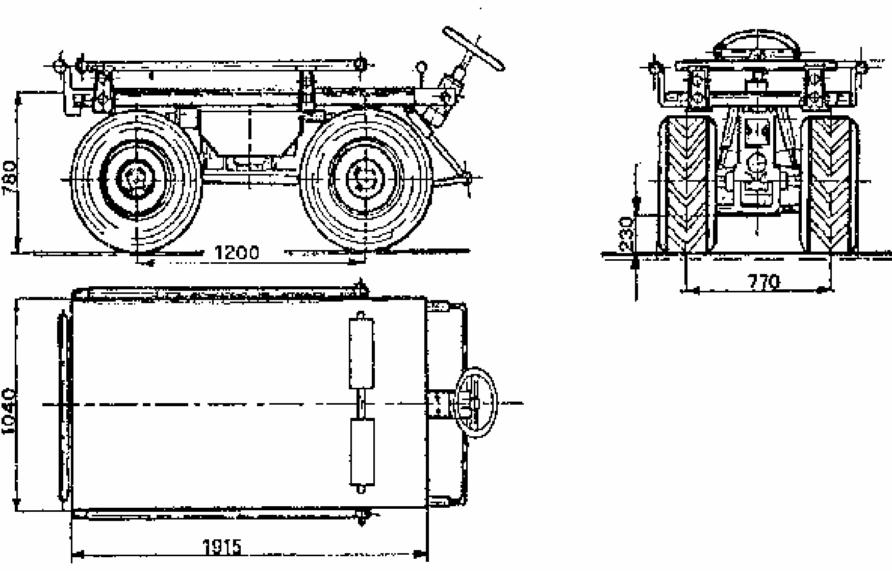

This vehicle has quite a long heritage, used in mountainous terrain, but it is still made in Italy by Fresia.

It could be a straight swap for a quad bike ATV if a reduction in speed could be accepted. On the upside, it can carry 400 kg and tow 500 kg so in return for lower speed, there is a potential for more capacity in any given combination of A400M CDS packages.

The 1,040 mm width and 1,915 mm length are compatible with a double CDS.

There is a dedicated YouTube channel, click here.

Sub-Compact Tractor

Sub-compact tractors can be considered a more conventional one-for-one replacement for quad bike ATVs than the two-wheel tractor.

Reduced-width sub-compact tractors are a specific niche category used for vineyards and orchards, but one that provides options smaller than 48″ wide.

Example manufacturers include Pazagilla, John Deere, Farmtrac, Branson Tractors, Claas, Landini, LS Tractors, Zetor, Bad Boy, Star Tractors, Shibaura, New Holland, Tym, Kioti, Kubota, Captain, Massey Ferguson, Solis, Iseki, and BCS

Despite this, there are very few that meet the dimensional constraints, and of those, even fewer have much of a margin for rigging materials so although I show one of these below, it would be marginal.

The Kubota B1181 is such an example, at 635 kg, its midpoint PTO betrays its heritage as a ride-on mower!

Although not common, tracked sub-compact tractors are available that fit inside the CDS dimension and weight constraints.

This one from Mira in Italy, for example.

At 910 mm over tracks wide, 1,800 mm long and weighing less than 600 kg, it would be a comfortable load for a double CDS. Unlike a quad bike ATV, this has a three-point rear lift and a PTO for attachments and tools.

A Rollover Protection System can also be fitted.

A larger tracked sub-compact tractor than above is the Fort-IT Horizon

Other examples include Geier Series 45, Vitrac Tool Carrier, and Camisa TR615.

The tracked crawlers will be even slower than the wheeled sub-compact tractor, but they provide much greater tractive force and mobility, whilst retaining the ability to attach tools.

Other

There is a collection of alternative trailer prime movers that are interesting, although perhaps less well-developed or industrialised.

DTV Shredder

The DTV Shredder, from Canada, is a leisure and utility-tracked skateboard, now available in an electric version.

Although it can only tow approximately 350 kg, it is quite compact when folded, easily two per single CDS pallet, although it only has a two-hour runtime.

MTT-154

I wrote about this a while ago, and think it is quite an interesting and well-designed concept.

The MTT-154 is an electric all-terrain tracked ‘tug unit’ that can be used singly or connected, and operated as a ride-on or via remote controls, used to push, pull or carry loads and trailers.

One of the more interesting aspects of the design is the ability to connect multiple units together for a greater payload. They can be connected inline (like a snake), side by side, or in a quad configuration.

The side-by-side configuration can also have a load bed platform between them, similar to the Milrem Themis. The difference between this and the Milrem unit is that the centre is not fixed, so can be added after digging.

At 23″ wide and 88″ long, two could be carried side by side on a double CDS skid board, and because they are so low, at 25″ high, they could easily be stacked, like the two-wheel tractor A400M configuration, but much more versatile and with extreme mobility.

The unit is a single-track device, powered by a number of lithium-ion battery packs. 1 battery provides up to 4 hours (35 km) of runtime, with three allowing up to 12 hours of runtime or a 105 km range. The system can also be used to provide export power for power tools or other battery charging.

Batteries can be quickly swapped, and unlike the two-wheel tractor, cannot be heard from 3 weeks away, top speed is also a more respectable 24kph.

A single unit can carry up to 250 kg on the load bed and tow 1.4 tonnes on a flat surface, reduced to 450 kg in extreme terrain.

There are some great videos of it in action on their website, it is a gem of a vehicle.

Movex Track-O Cross Country

The French company Movex has a similar concept to the MTT-154 called the Track-O Cross-Country, although it seems more tilted to on-site construction and industrial tasks.

It has a much shorter run-time of only 2.5 hours but can carry 1,039 kg on a flat surface.

Mattro Ziesel

The Mattro Ziesel was originally developed as an off-road wheelchair, but it has been developed by some partner organisations to develop usage in agriculture, such as the Aebi EC-170 that has a front-mounted PTO.

With a 60-degree side slope, low ground pressure, and a top speed of 35kph, they are more mobile over extreme terrain than a quad bike ATV.

With a low centre of gravity, integral folding roll bar and four-point harness, they are likely to be much safer than a quad bike ATV and there is even a road-legal version

Their towing capacity is equally impressive, over a thousand kilograms at ten degrees incline.

It is too wide for CDS but use a folding chair, and because it is battery-powered, it should be OK to rig vertically so it would fit within the constraints of a double CDS.

Thus, it could be a drop-in replacement for a quad bike ATV, although, with only a 3-hour battery life, spares or a charging facility would need to be included.

Like all these electric designs, battery life is a key limiting factor to employment.

Hawe Mattro now has developed a more compact version as a base platform for UGV developers, including Dhiel, as part of the Integrated Modular Unmanned Ground System (IMUGS) demonstration.

Again, too wide for CDS, so would need to be vertically rigged.

Engineering Plant

The image below shows a runway repair operation supporting the evacuation of British nationals from Sudan in April 2023

France also did similar in Mali a few years ago but with a parachute-delivered force, making use of engineering plant to clear.

Airfield Damage Repair uses much the same basic equipment as any field squadron such as bulldozers, backhoes, loaders and compactors, except with the addition of some specialist items like dynamic compactors, screed beams and power brushes.

Towed Excavator

There are some attachments that can be used with quad bike ATVs, but they are relatively limited.

Tow behind excavators are not new, indeed 90 of them were purchased by the British Army in the mid-eighties from Powerfab. The Powerfab 125TW was powered by a 10hp engine and was capable of digging to a depth of 2.6m.

Powerfab went out of business but is now back trading, although with a reduced product range, perhaps we could pay them to resurrect the 125TW?

The Kellfri Backhoe Digger also runs from a 10hp engine but does not have the hydraulic export feature of the Powerfab or quite the digging depth. As can also be seen, it does not have independent travel capability. At £3,600 each though, pretty cheap, and at less than 500 kg, relatively easy for the in-service quad bikes to tow.

Using detachable wheel arms, they would be within CDS limits.

Tractor Attachments

Both two-wheel tractors and sub-compact tractors described above can be fitted with various attachments to extend their usefulness beyond that of a trailer prime mover.

Clearing runways of small rubble with a powered brush is much faster than a hand broom.

Snow clearance blades, snow blowers, stump grinders and flail mowers could also be used with two-wheel tractors.

Sub-compact tractors offer a much wider range of front and rear attachments including forestry winches, post drivers, loading shovels, clearance blades, backhoes, pallet forks, demolition grapples, root grapples, plate compactors, and grader blades.

and when fitted

Backhoe

These would all need to be carried on a separate CDS pallet and attached once on the ground after de-rigging.

PTO-driven pumps, generators, compressors, and welders are available, extending the versatility of the two-wheel or compact tractor, and reducing the number of engines used for any given task.

Sub-Compact Excavator

Although a backhoe excavator could be fitted to a sub-compact tractor, a dedicated machine would provide more versatility.

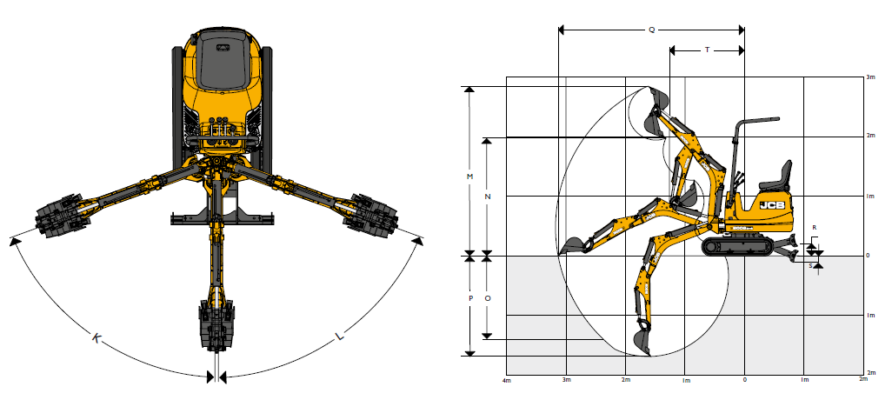

The 875 kg JCB 8008 CTS micro excavator is designed for small spaces at 700 mm wide, and so fits within CDS constraints, although it would be at the top end of allowable weight.

The width would not be a problem, but the overall length would be to the 2.4-metre limit and so, like the Kubota sub-compact tractor described above, would need testing as suitable.

Each of the attachments shown in the image below would be a useful addition.

The 380 kg Komatsu PC01-1 is another, and smaller, example.

Sub-Compact Bulldozer

The Struck Magnatrac RS1000, despite its rather amusing appearance, is surprisingly capable, the newer RT1150 has similar dimensions.

It can be fitted with rubber tracks, a rear ripper blade, a number of different dozer blades, front excavator buckets, and even a backhoe kit with a digging depth of 2m.

The video below gives a good overview.

There are more capable machines in the Struck range, but they go right to the 48″ width limit, so have excluded them from this post.

The tracked sub-compact tractors described above could also be fitted with a dozer/clearance blade.

Sub Compact Wheeled Loader

Beyond the major construction manufacturers, there are also a number of less well-known brands that continue to thrive in this sector; Avant, Multi One, Sherpa and Norcar, for example.

The Avant 225 can lift 350 kg to a height of 1.4m.

With a folding ROPS and no attachments fitted, within CDS limits.

It can be fitted with a wide range of attachments, brushes, excavators, pallet forks, snow clearance blades, augers, post drivers, and winches for example.

Stand on Loader

Most conventional skid steer or tracked loaders tend to be quite heavy, so the industry has responded by creating stand-on versions to reduce weight. Ditch Witch, Bobcat, Sherpa, Wacker Neuson, Kanga, and Vermeer, all have a range of models.

Most of these are still beyond CDS limits.

Because of the unique method by which it changes attachments, the Ditch Witch Zahn is an unusual machine in this regard, it fits.

Ditch Witch has a wide range of industrial strength attachments for the Zahn.

Other

Walk behind tandem vibratory rollers, plate compactors, dumpsters, and other portable construction plant are small and light enough for CDS, although they will, of course, not be as capable as larger models.

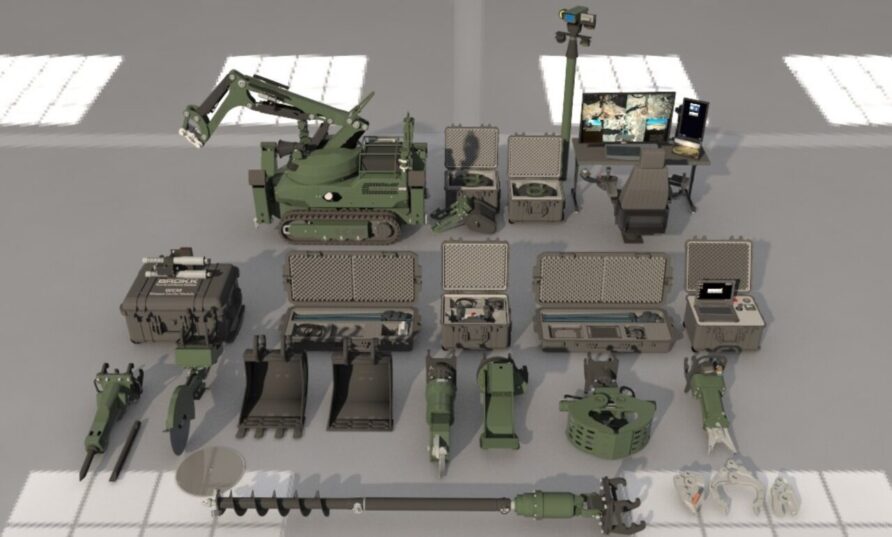

A couple of interesting products do stand out, the Brokk 70 demolition robot and 954 BBT Mini Transporter because they are both well realised and compact enough to fit inside a double CDS.

When stowed for transport, they are very compact, and a larger variant, the Brokk 11 would also fit.

There is a wide range of construction and demolition attachments available

Brokk also has a defence and security division, but none of the platforms at this link would fit inside a double CDS.

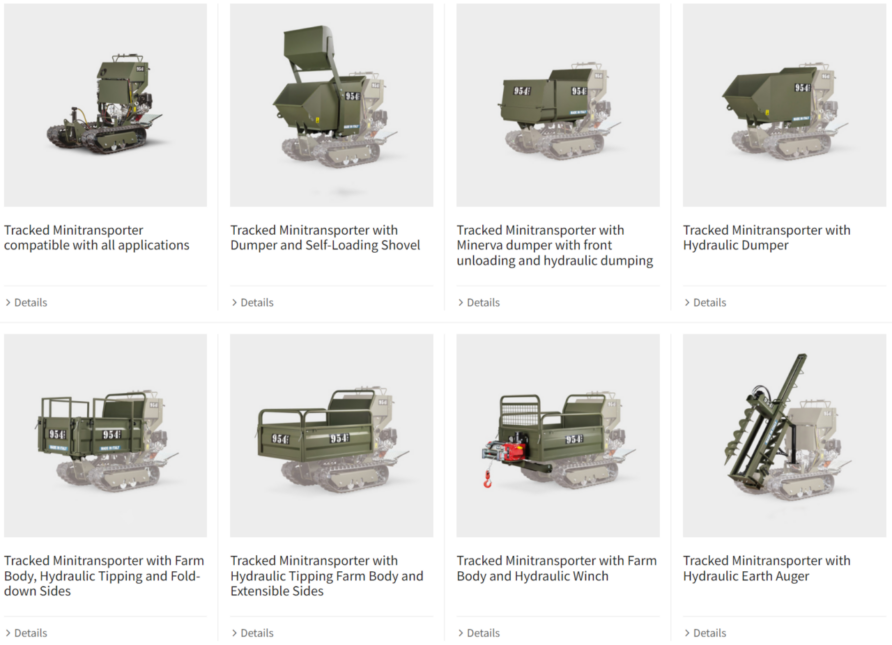

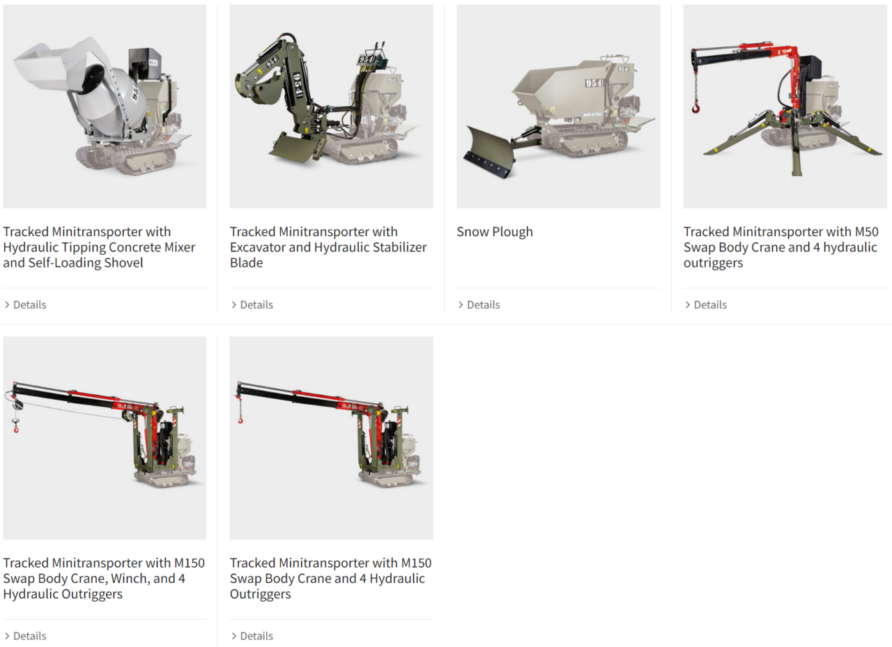

The BBT mini transporter starts with a single base unit.

And then, similar to Boxer, can have several modules fitted to cover a range of different site tasks. Cranes, mixers, backhoe, dumpsters

Weapons and Systems

Using door bundles, CDS and equipment carried on the person, parachute forces can make use of 81 mm mortars, hand-held HVM, Javelin ATGW, .50 Cal HMG, and 40 mm GMG.

This is a not insignificant amount of violence, but still limited in range, endurance, and effects.

And no modern weapon system is light.

Without mobility support, there will always be limits to the amount of ammunition available and the distance parachute forces can influence beyond the landing site, no matter how supremely fit individual soldiers are.

Expanding transport options achieves many things;

- Increases area over which the parachute force can exert influence

- Increases the amount of ammunition available for existing weapons like mortars and Javelin

- Increases scope for heavier weapons to be employed

- Increases scope for complementary systems to be employed, e.g. UAS, C-UAS, and loitering munitions

Artillery and Air Defence

The 105 mm Light Gun is far too large for CDS.

Although no longer in production, the Oto Melara 105mm Mod 56 Pack Howitzer, when broken down, would actually fit. There are thousands still in service, and some have even been gifted to Ukraine, but it seems unlikely we would go second-hand shopping.

Something more modern like the Mandus Hawkeye low recoil 105 mm weapon system still has too long a barrel and hasn’t been produced in a dismounted variant.

Perhaps there is a niche for Mandus, to recreate the pack howitzer concept, a short barrel low recoil weapon that could be easily broken down into multiple components for transport

If not, a larger mortar is probably the easiest option to improve firepower.

Whilst there are many vehicles with integrated 120 mm mortar options available, in this application, it probably makes more sense to simply use a conventional system with the trailer options above.

Systems from Expal, Hirtenberger, and Thales spring to mind, with up to 10 km range in some cases, about the same as the Pack Howitzer.

Keep it simple, like the 8 km range Expal 120-MX2-SM shown in the image below, but with a narrower trailer.

120 mm mortars have a large user base and an equally diverse manufacturing and development ecosystem.

Extended range and guided natures are available, the Elbit Iron Sting or example.

This would give a parachute landed force a significant capability improvement over 81 mm mortars, and still CDS compatible.

Other non-line-of-sight complex weapons that could be included in a double CDS package include EXACTOR and Ground Lunached Brimstone.

If EXACTOR remains in service, the existing launch trailer could potentially be re-engineered to fit inside a double CDS-compatible trailer, although the guidance and supporting equipment can be quite bulky.

A precision with human-controlled terminal guidance out to a range of approximately 25km, useful for a parachute landed force?

With a shorter range, but lighter, and with flexible guidance, ground-launched Brimstone could provide the same parachute landed force with a powerful anti-armour blocking/ambush capability at greater ranges than Javelin and without the need to expose the firing point.

The Milrem Themis in the image below is too wide, long, and heavy for CDS, but the six Brimstone launcher box isn’t.

On a suitable trailer, it would be comfortably inside CDS dimension and weight constraints.

The image below shows a Hellfire II tripod launcher, but with suitable development, I wonder if the same could be done for Brimstone 3, given its similarity in external form.

The recently ordered Saab Giraffe 1x is a compact system, does not need any air conditioning and runs off standard power supplies.

Although it can be broken down into smaller sub-assemblies for carriage, I’m not sure if those sub-assemblies would fit with a single or double CDS.

Hopefully, it would, together with C-UAS effectors, the Air Defence Alerting Device (ADAD) and something like a HVM/LMM Shoulder Launched Aiming Unit or Lightweight Multiple Launcher, it would be a powerful air defence system.

Direct Fire

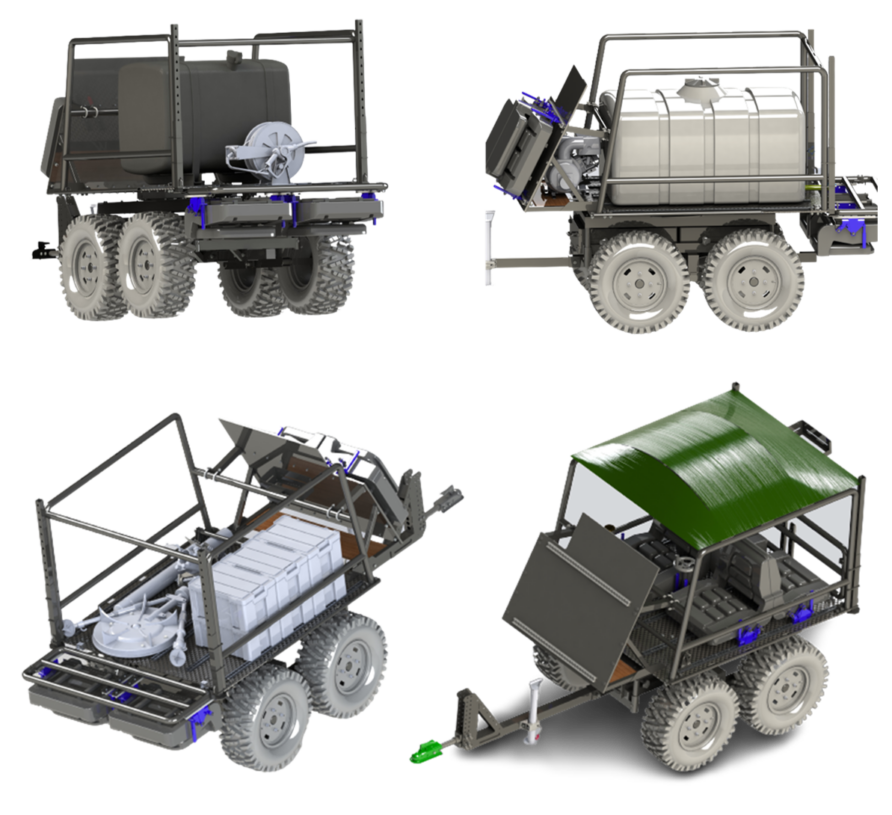

The LV-TEH Combat Support Platform (although slightly oversized for CDS), shows a glimpse of what could be achieved.

The 118 kg Nobles Viper gun mount uses a manually aimed 30 mm M230LF, maintaining ammunition commonality with Apache.

Closer to home, AEI has developed a cheaper and ITAR-free 30 mm automatic cannon called the Venom-LR.

The British Army has recently trialled this with an Unirobotics Trakkon RWS on a HIPPO HAWC uncrewed platoon load-carrying vehicle (just for reference, that vehicle won’t fit either)

The length is just over 2m and with a total weight of 122 kg without ammunition, not difficult for CDS.

There is a wide range of 30×113m ammunition available, so it would be a significant direct firepower uplift.

Other Systems

As long as it fits inside boxes and inside the footprint of a CDS-compatible trailer, there are no practical limitations to the types of equipment that can be carried.

Be that UAS, loitering munitions, tethered UAS, short gap crossing, Light Electronic Warfare (as shown below), medical, communications, command spaces, EOD robots, UGV, CBRN detection equipment, airfield lighting or air traffic control.

Summary and Thoughts

The amount of time and resources we spend on this should be proportional to the value we ascribe to parachuting capability in general.

I appreciate this can be quite a polarising subject but do think, despite what the Russians did in Ukraine, parachuting retains a broad applicability to contemporary UK defence and is therefore worthy of future investment.

And when I say investment, I don’t mean Ajax or Boxer size investment, I mean some better trailers’ investment.

There also has to be an ongoing commitment to incremental improvement, finding value in better load securing on a trailer might not be as attractive to careers as the big ticket items and high-level concepts, but it is no less worthy of intellectual investment.

C-130 has gone, and C-17 is always in demand elsewhere, no point in complaining about it, the future of 16 Airborne Brigade is the A400M.

Until we invest in a large vehicle despatch platform for the A400M, CDS or double CDS weights and dimensions are the absolute and undeniable constraint.

16 Airborne Brigade is not just the Parachute Regiment, engineering, signals, medical, logistics, and artillery personnel also wear a maroon beret.

Without stores and equipment, and reliant on what can be bundled out the door or carried on a soldier’s back, there is a large credibility gap to be addressed.

Stick with Quads

As much as I love the idea of each one of those quad bike ATV alternatives, especially the Fresia F-18, MTT-154 and Matros Ziesel, the quad bike is here to stay. Until battery systems improve, the energy density of fossil fuels counts for a lot when every kg counts.

We should still be getting experience with these novel systems, but our priority should be to achieve some almost imperceptible improvements with the Yamaha’s, i.e. racks and storage boxes, including Rotopax fuel and water containers.

Be Obsessive about Trailers

Accepting the longevity of the quad, the primary focus should be on working with a manufacturer to create a modular and adaptable trailer that maximises the space allowed by a double CDS.

There might not be a huge addressable market, but this is fairly basic design and manufacturing.

The detail for each component should be obsessed over!

Trailer Frame and Deck

A flat deck sized to accommodate two 1.1mx1.1m pallets or a 2.16m × 1m pallet box would provide maximum load space.

This size also retains broad dimensional compatibility with Zarges K470, Peli ISP2, and CP Cases Amazon Rotomoulded Cases, in addition to being able to support most of the examples of small engineering plant and systems described above.

Pull-out ramps (like ATMP) would also allow small wheeled or tracked plants and pallets to be loaded without a hoist or crane.

Like this excellent design from Off Road Designs in Australia.

The deck itself would benefit enormously from using something like the Koller Engineering floor system with load-securing fixture rails.

This would allow various tie-down clips and lashing fixtures to be used. Although this has origins in the disabled mobility sector, they have been rigorously tested and assured against significant impact loads for wheelchairs and seats. The Supacat Jackal uses them.

It might also prove useful to embed the 10cmx10cm inter-stacking pattern that Peli ISP2 and CP Amazon cases use to provide lateral stability.

And Molle panels everywhere, of course.

With a flat deck, the trailer could be double stacked for air despatch if required.

Trailer Coupling and Undercarriage

If the trailer coupling was removable using captive split pins, it could be stowed under the deck for air despatch. This allows the deck size to be maximised whilst still compliant with the maximum length allowed by a double CDS.

Twin wheels (preferably the same as the quad bikes) should be underneath the deck, not to the side. This would result in a higher deck, with an attendant reduction in stability, but it is the only way to maintain load space without exceeding CDS width limits.

The rear of the undercarriage frame should have a secondary towing hitch pintle, so another trailer can be daisy-chained if the towing vehicle has enough power.

With an increasing focus in the High North, it would also be worthwhile to have the ability to replace wheels with skis, and whilst we are at it, helicopter slinging and pontoon attachment points (like the Pac Rat trailer from the USA)

For commonality, those pontoons could be from the in-service Infantry Assault Bridge, compatible with the new and various Easibridge systems

Build Out From There

Without wishing to sound like a trailer-obsessed weirdo (stand fast you lot), it really is the foundational element of any means of exploiting CDS further.

I am also not a fan of making the trailer too integrated with equipment and systems because the more you do that, the more you make any capability contingent on not having a flat tyre.

So, any additional capability should be demountable from the trailer or self-propelled, capable of being used independently of it.

This is why we should pay attention to boxes, pallets, and trailer ramps and fittings, but you knew that.

With a suitable longer-term plan, capabilities could be built out from boxes, trailers and demountable vehicles that span the full gamut of 16AAB capabilities, like Lego.

Everything from applied violence to deployable runway lights.

None of this kit, especially the engineering plant, is what could reasonably be described as ‘heavy duty’ so it must be seen in the context of being better than hand tools.

And finally, none of our kit is getting any lighter, whilst a quad bike trailer is not a MAN SX, it is better than Shanks’ Pony

See you in the comments.

CHANGE STATUS

| Date | Change |

| 29/08/2023 | First published |

| 29/02/2024 | Added additional small plant examples |

Read more (Affiliate Link)

I love your atricles they are so amazinly detailed! I learn a hell of a lot from them!

Thank you for putting in all the time and effort, as im sure they take a hell of a long time to do!!!

And then the requirement gets "over-egged" and "gold-plated" by HQ Land, followed by DE&S applying god knows how many DefCons and DefStans, and it will be 5 to 10 years to In-service date at 4 times the original price. Such is the sad state of Army procurement.

The MTT-154 is a fascinating thing to watch. How does it steer with only one track? It doesn't say on their website.