The end of WWII was followed by a period of reflection for the British Army, but not a long one.

On March 5, 1946, Winston Churchill delivered his ‘Sinews of Peace’ speech.

In the transition from War to an Uneasy Peace, it became obvious that many new vehicles were needed.

Although the 1945 British Armoured Division suffered from a lack of protected mobility for its infantry, it was a well-honed and balanced organisational construct (1 infantry and 1 armoured brigade).

The other problem was it had too many types of equipment, far too many.

The Need for Standardisation

Faced with an almost impossible industrial and manufacturing problem, the early days of the war meant the British Army had to make do with what vehicles it could.

The diversity of equipment in combat and support arms placed significant strains on logistics, support, and training. The more vehicles, the more spare parts, the more spare parts, the smaller economies of scale.

The lack of commonality across components and standards in such seemingly mundane items as screw threads resulted in large quantities of equipment being abandoned in North Africa between 1941 and 1942.

[American sources estimated this lack of standard threads alone added £25m to the cost of war. Over a billion Pounds today when adjusted for inflation]

As the war closed, a period of taking stock was in order.

With wartime pressures to maximise production from different manufacturers gone, the demand for standardisation and a reduction of vehicle types was a vital requirement of the Ministry of Supply.

In 1951, Major R Campagnac RASC and Major P E C Hayman of the 15th/19th The King’s Royal Hussars published their review of wartime transport.

The Second World War 1939-1945: Army Fighting, Support and Transport Vehicles and the War Office Organisation for their Provision, The War Office, 1951

The report was published in two parts

- Fighting Support and Transport Vehicles and War Office Organisation for Their Provision: Part 1, Common Problems, 1939-1945

- Fighting Support and Transport Vehicles and War Office Organisation for Their Provision: Part 2, Unarmoured Vehicles, 1939-1945

It noted that by the end of 1944, there were over 600 makes/variants of support and transport vehicles in service with the British Army and much of it was based on civilian designs that were unsuited to military use.

Several objectives for consideration came from this.

- The Army had to improve the precision and clarity of its requirements

- A research and design establishment must be set up to realise these requirements

- Manufacturing of military equipment must be done with standardisation in mind

- Military transportation equipment should be designed for military requirements

As the War ended and various pieces of the Ministry of Supply were closed, and some establishments merged, in 1952, the Fighting Vehicle Research and Development Establishment (FVRDE) was created, located on Chobham Lane in Chertsey.

Standardisation meant as few engines, transmissions, wheels and other components as possible.

Vehicles of different designs would be designed and built around these common components, especially engines, 60, 90, 180 and 350 BHP power specifications depending on vehicle type.

Other features of the resultant requirements included four-wheel drive as a minimum and the potential for small arms protection for the crew and engine.

Vehicles would be designated according to their role and specification.

- CombaT (CT), built to exact General Staff requirements, and thought to be about 16% of the total requirement

- General Service (GS), civilian designs adapted for military use under FVRDE guidance, approximately 39% of the total requirement

- Commercial (CL), civilian designs with minimal military modifications, approximately 45%

Transport Vehicles

Land Rover

A long story, and is far too much for even a long blog post, but the story of Land Rover is the story of the Austin Champ, or more specifically, the over-ambition of the Austin Champ.

The Champ had an advanced design, even having independent torsion bar suspension and incredible fording capability, but it was expensive.

By the mid-fifties, the need for the sophisticated Champ was being questioned, especially when a Land Rover was less than half the price.

The rest is history, from 1958, the Land Rover became the British Army’s standard light general service vehicle and is so to this day.

The Champ was a CT, Land Rover wasn’t.

Humber 1-Ton Truck

The Truck, Armoured, 1 Ton, 4×4 (or Humber Pig) was based on the FV1600 series trucks produced by Rootes Group and designed by FVRDE.

Manufacturing started in 1952, following the first prototype in 1950.

As can be seen in the image below, the Humber had a complex and well-styled body compared to other military vehicles.

Although expensive, the Humber did perform well, it was a CT vehicle.

3,700 Humber’s were produced.

Bedford RL

The Bedford RL was a 3 Ton vehicle that was taken into service because of a dawning realisation (with experience from Korea) that the Ministry’s grand plans for CT (CombaT) vehicles were unrealistic.

Bedford produced a prototype vehicle precisely 3 weeks after an enquiry letter from FVRDE asking about the general possibility of supplying 6,000 trucks!

The RL was a 4-wheel drive version of the Bedford S Type, unlike the CT types, it did not have a B Series engine.

Over 73,000 were eventually produced and it remained in service for three decades.

There was even a Bedford RL ‘Pig’

A year after the enquiry letter, a production contract was signed for the FV13100, with over 200 variants being eventually produced.

Like Land Rover, the RL was not a CT vehicle.

Leyland Martian

One of the first post-war attempts at producing a dedicated military transport vehicle using standard components was the Leyland Martian, it being a CT vehicle.

The Leyland FV1100 was a 10-ton, 6×6 design that would be available in a number of wheelbases and configurations, with approximately 2,000 being built, including an artillery tractor, cranes and recovery vehicles.

AEC Militant

The 10-ton AEC Militant Mk2 and Mk3 were developments of a WWII vehicle called the AEC Matador.

Development of the ‘Knocker’ started in 1951 with production stretching into the early sixties. It was a commercially derived alternative (GS) to the Leyland Martian (CT)

Many variants were produced, including cargo, artillery tractors, cranes, and recovery vehicles

The Militant was much more successful than the Martian, again, CT versus GS.

Before reading on, would you mind if I brought this to your attention?

Think Defence is a hobby, a serious hobby, but a hobby nonetheless.

I want to avoid charging for content, but hosting fees, software subscriptions and other services add up, so to help me keep the show on the road, I ask that you support the site in any way you can. It is hugely appreciated.

Advertising

You might see Google adverts depending on where you are on the site, please click one if it interests you. I know they can be annoying, but they are the one thing that returns the most.

Make a Donation

Donations can be made at a third-party site called Ko_fi.

Think Defence Merch

Everything from a Brimstone sticker to a Bailey Bridge duvet cover, pop over to the Think Defence Merchandise Store at Red Bubble.

Some might be marked as ‘mature content’ because it is a firearm!

Affiliate Links

Amazon and the occasional product link might appear in the content, you know the drill, I get a small cut if you go on to make a purchase

Wheeled Armoured Vehicles

By the close of WWII, Germany remained convinced that wheeled vehicles were best for reconnaissance tasks, while the US preferred tracks.

Although the British Army had used wheeled armoured vehicles for reconnaissance for as long as they had armoured vehicles, towards the end of WWII, these were joined by light and medium tanks from the end of 1944 until the close of WWII.

The British Army decided to stay with new wheeled vehicles in the reconnaissance role, consolidating the motley collection of armoured and scout cars into a single pair of designs.

Ferret

As a successor to the very well-regarded Daimler Scout Car, the MoD developed a requirement in 1947 for what would go on to become the Ferret.

Daimler was awarded a development contract in 1948, with the first prototype being ready for trials in 1950.

The Car, Scout, 4 x 4, Liaison (Ferret) Mark I, FV710 Ferret, entered service in 1952, the same year as manufacturing started.

The basic design of the Mk1 Ferret was similar to its predecessor, with central differential and parallel drive shafts affording a low profile, comparable to many tracked vehicles. The most significant difference was that the Ferret used a single monocoque hull, rather than having an armoured body fitted to a chassis.

Ferret also made use of the same B Series engine design as Saracen and Saladin, although in a lower-power variant.

The Mark 2 variant was developed for reconnaissance role, being designated Car, Scout, 4 × 4, Reconnaissance (Ferret) Mark 2.

The main difference in the Mark 2 was the addition of a turret armed with a .30 in. Browning machine-gun. Apart from that, there were no differences so it was put into manufacture without any significant prototype work.

Mark 2 actually entered service before Mark 1, with the former becoming much more numerous and remaining mostly unchanged until it left service.

Ferrets were used in their conventional role but also as air portable armoured vehicles, the Life Guards being flown into the Aden Protectorate with theirs in 1955 being a good example.

Trials were also completed on developing fording and amphibious modifications.

Air despatch equipment was also developed for the Ferret

After over 4,400 were built, it would leave British Army service in 1971, and see service with 24 other nations.

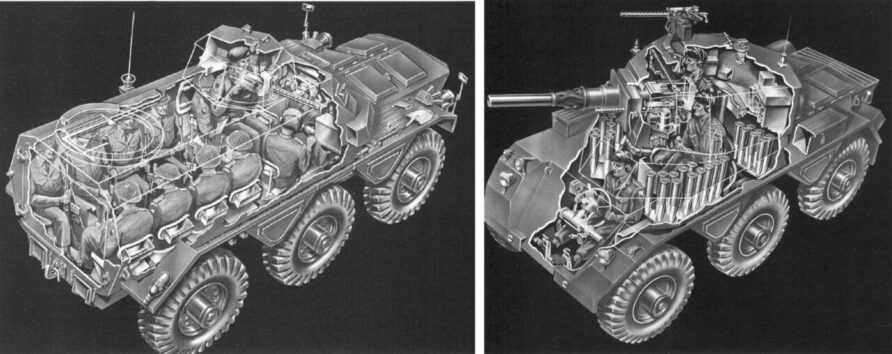

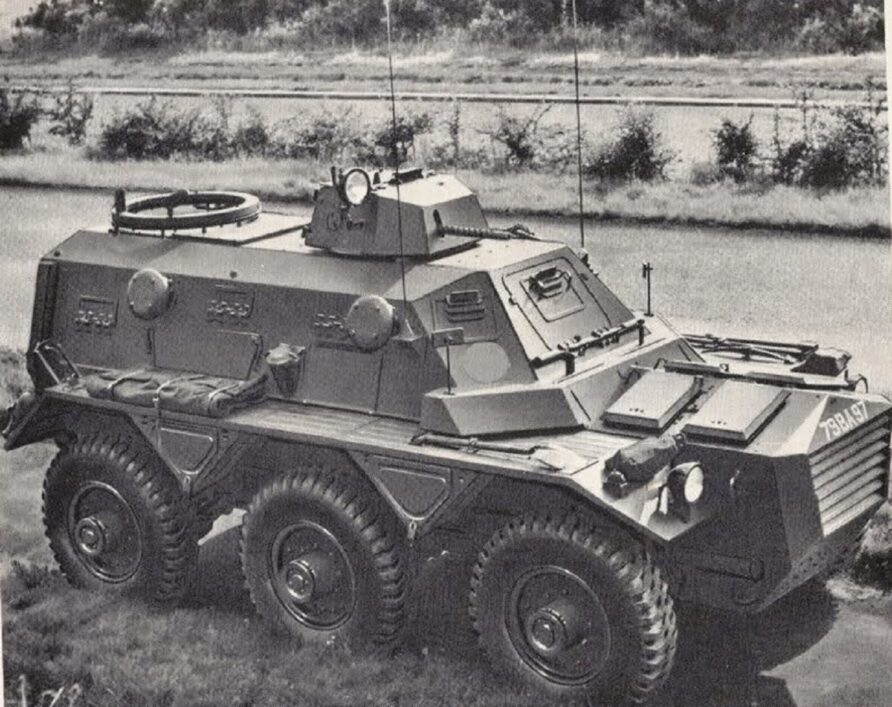

Saladin and Saracen

The General Staff Operational Requirement was issued in 1946 for what would eventually become Saracen and Saladin.

The British Army rejected further development of the two-axle Coventry armoured vehicle and retained in service the Daimler MkII and AEC Mk III until a new vehicle could be introduced.

With this in mind, work started on defining a requirement for a high mobility wheeled fighting vehicle design that could operate in all environments and offer a high degree of commonality between variants.

One of the first issues to resolve was the number of axles; a two-axle design was discounted because of mobility and weight-carrying concerns, and an eight-wheel design was discounted because of the weight and complexity.

A 6×6 design was ultimately thought to be the best compromise.

The US T19 (based on the T18E1), the T28 and T66 were all examined and generally considered to be a good series of general design concepts to emulate, especially the T28 with its independent suspension, although there is no direct link.

The requirement envisaged a 3 or 4-man crew, 6×6 vehicle armed with an improved version of the 39 mm 2 Pounder as used on the AEC, Daimler, Coventry and Marmon-Herrington armoured cars.

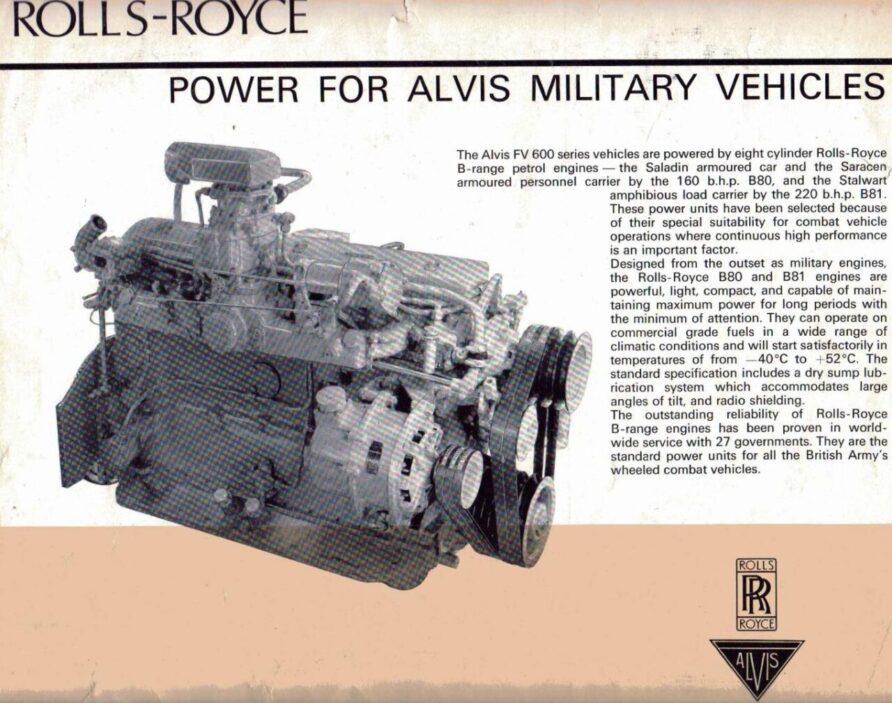

The weight rose slightly during later versions of the requirement, creating an opportunity for using an emerging concept in standardised military engines; the Rolls-Royce B series.

This standardised engine series design also meant the elimination of different thread types and the resultant need for two sets of tools and fastenings.

High reverse speed, ease of servicing, mobility and vision were also key elements of the requirement.

Protection was defined as the ability to withstand 7.93 mm Armour Piercing from all angles, 25 Pounder (equivalent) shell splinters at 9m and a 9 kg mine under any wheel, close to Level IIIa in today’s standard, STANAG 4569.

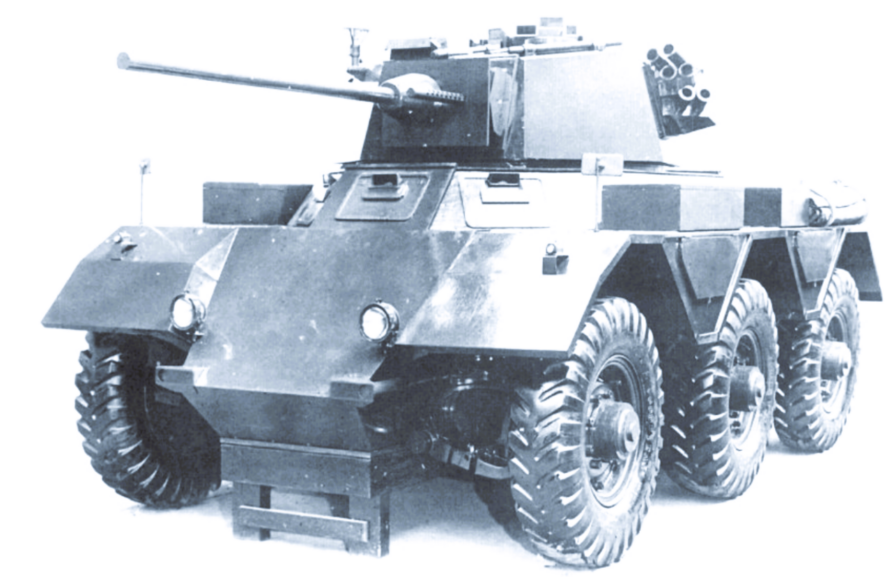

The image below shows an early wooden mock-up, produced by the newly renamed Fighting Vehicle Research and Development Establishment (FVRDE) with the 2 Pounder.

A contract was placed with Alvis in 1947 for the production of two prototypes of the FV601, one of which was subcontracted to Crossley Motors.

The image below shows chassis testing with weights in place of the turret.

Doubts about the specification began to set in almost as soon as Alvis had started work, specifically in relation to the main armament.

After much back and forth, the Armaments Design Establishment (ADE) decided to develop a brand-new gun specifically for the vehicle; the 76 mm L5A1.

This larger gun displaced the third crew member from the earlier turret design.

Saladin could be reasonably described as being built around two components;

- The Rolls-Royce B Series Engine

- The L5A1 76 mm Gun

Other requirement changes resulted in modifications to the turret layout, along with more delays.

Saladin was intended to carry out the following tasks.

- Reconnaissance including advance-to-contact battle reporting, observation and surveillance, and rapid forward recce

- Delaying action in withdrawal

- Flank guards

- Anti-airborne and anti-helicopter borne operations

- Independent raids and deep penetration tasks

- Escorting unprotected columns

- Exploiting a gap in the advance

- Internal security; mobile patrols, anti-arms smuggling patrols, roadblocks, escorts for convoys, IS operations, peace-keeping duties, national, international, NATO, etc., and communication tasks.

- Counter-insurgency tasks; armoured close support of infantry, and fire support when artillery is not available or unable to get into action.

During the development phase, Saracen was prioritised over Saladin to provide protected mobility vehicles for Malaya.

The image below encapsulates this, leading the patrol is a Daimler Armoured Car, not a Saladin.

By the mid-fifties, Malaya had been stabilised to a point where the large numbers of Saracens originally envisaged were no longer required and the focus shifted back to Saladin.

Production of the Saracen was then slowed to allow export production orders to catch up.

It wasn’t until 1958 that the FV601C Saladin Mk2 entered production, 13 years after the initial requirement was defined, and the design work had started.

Production of Saladin ran from 1958 to 1972, with 1,177 built, and operated by 26 nations.

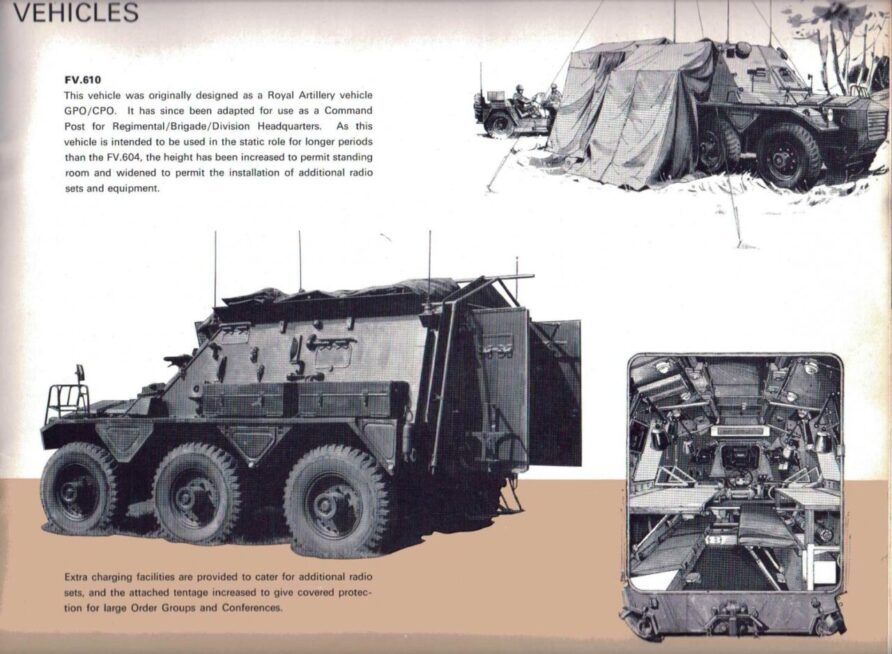

Two other vehicles were originally envisaged as part of the FV600 series

The FV602 Command Post and FV603 Armoured Personnel Carrier.

Both were thoroughly modern concepts for the time, but the vehicle design limited the practicality of the Command Post variant, and it was soon dropped.

However, other command post variants would appear later.

The FV603 was entirely a different matter.

In 1948, a state of emergency was declared in Malaya and by 1950 plans were being formulated by Lt Gen Harold Briggs to direct the anti-communist campaign. This evolved into a concerted anti-terrorist campaign that would have no need for tanks or artillery.

The battles would instead be fought in terrain that favoured the ambush.

Therefore, dismounted infantry – supported by small armoured cars – was the preferred option. Something more substantial than a truck would also be needed to provide some measure of protected mobility to the infantry.

Step forward FV603 Saracen.

Despite still being in development, it was thought to be an ideal vehicle. Saracen was designed to be no wider than 8ft (2.44 m) to fit between the rows of rubber trees on Malayan plantations, a key specification that would be carried through to CVR(T).

The development of Saracen was prioritised over Saladin.

The first delivery of the prototype was made in June 1951. Two had been delivered directly to Malaya for field trials in the actual field it would be used in!

Testing revealed several problems, but for the most part, these were resolved in subsequent iterations before large-scale production commenced.

The first production order was for 250 of the FV603a variant, later designated Personnel Carrier Mk1, shown below in Coventry

In 1952, the FVRDE issued a production specification that comprised a number of sub-variants

- FV603a Personnel and Load Carrier

- FV603b Regimental Command Vehicle

- FV603c ASSU ‘Tentacle’ or signals

- FV603d Armoured Ambulance

- FV603e Royal Artillery Radar Vehicle

- FV603f Royal Artillery Sonic Detection Vehicle

- FV603g Infantry Command Post.

Wading trials continued throughout the period for both Saladin and Saracen

As did air despatch and carriage

Another couple of variants emerged by the end of the decade

Experience showed that when compared to tracked vehicles, Saracen and Saladin could be used over extended durations without impairing crew and passengers.

Neither would be completely immobilised by a mine strike.

Humber Pig

Although many associate the Humber Pig with the ‘Troubles’ in Northern Ireland its heritage goes back to the fifties.

It was based on the Humber 1-ton truck described above.

Sankey was contracted in 1952 to produce an armoured version, designated FV1609. The finely crafted body shape of the Humber truck was replaced with a much more workmanlike armoured cab.

By the end of the fifties, a number of the earlier designs had been converted to the Mk1 Pig

The FV1611 (Pig) was the armoured variant of the FV1601 Truck and the FV1612, the armoured version of the FV1602 Fitted for Wireless (FFW) Truck. The FV1609 was an armoured version specifically designed for use in many roles with the Field Army.

The Pig was planned to be replaced by the Saracen, and it would serve in this role until enough Saracen were available.

Tracked Armoured Vehicles

The achievements of WWI were abandoned to neglect in the twenties and thirties, followed by a struggle through the early days of WWII.

The later arrival, in quantity, of US tanks, coupled with British weapons like the 17 Pounder on some of them and innovations such as the 79th Brigade and its largely Churchill-based ‘funnies’ allowed the British Army to redress the balance against German forces.

The realities of the ‘Iron Curtain, and within a few short years, Korea, were also joined by a rapidly demobilising British Army and an ocean of operational analysis to inform plans.

In 1945, Field Marshal Montgomery set out a demand for a Capital, or Universal tank, one that would replace the various types of light, cruiser, infantry, and tank destroyer.

‘One Ring to Rule Them All’

The previous visions of differing levels of mobility, protection, and firepower were skewed in favour of firepower and protection, in that order, with mobility third. No longer would British Army tanks be defeated at range because of poor protection and no longer would they be able to shoot back without devastating consequences for the enemy.

The 17 Pounder armed A41 in the Cruiser category would eventually be called Centurion, replacing Cromwell and Comet.

Going up a weight class into the Infantry Tank role, the A43 Black Prince was intended to replace the Churchill. A45 was scheduled to follow Black Prince in due course. Plans were made for the A45 to become the Universal Tank including flame-throwing, mine-flailing, swimming, bridge laying, and recovery variants.

It was soon realised that a predominantly A45-based tank fleet would be too costly, together with a realisation that the A41 Centurion could do just fine for many of the secondary roles, plans for the A45 were abandoned.

The A45 would later be resurrected as the FV214 Conqueror to serve in the tank destroyer roles, alongside Charioteer, but Centurion would remain in service much longer, and with many other nations, as the first universal tank.

Conqueror

Although the A39 Tortoise self-propelled gun used the 32 Pounder (adapted from the 3.7” Anti-Aircraft Gun), it was rejected in favour of a UK/US 120 mm design. This was mounted in a new turret in an FV201 hull, called Conqueror.

There are many great videos of the Conqueror, but this one shows just how sophisticated the fire control system was, and how advanced for Its time it was, using a contra-rotating commander’s cupola that allowed independent identification of targets and gun laying.

At 65 tons, and carrying on 35 rounds for its main gun, the design was partially limited.

Only 180 were built, serving as a heavy tank destroyer, until 1968, when it was withdrawn.

Centurion

The first version of the Centurion was equipped with the 17 Pounder main gun, mostly because it was available in quantity and was good enough. This was soon followed by the 20-pounder, in the Mk III, with a stabilised turret.

Centurion used a Rolls-Royce Meteor engine and Merritt Brown Z51R combined gearbox and steering unit, with Horstmann suspension.

The mobility (especially hill climbing), protection and outstanding long-range accuracy of the 20-pounder cemented the reputation of Centurion when deployed to Korea.

A monowheel fuel trailer was issued in 1953, but it was not well received by crews and was unreliable, being withdrawn not long after.

The 20 Pounder was in due course replaced by the RARDE-designed 105 mm L7, providing a 25% improvement in armour penetration over the 20 Pounder. The 105m gun was first fitted to a Centurion in 1959.

A wide variety of engineering and other specialised variants were produced from the Centurion hull.

Centurion was produced by Royal Ordnance Factory, Vickers Armstrong and Leyland Motors, with production ending in 1962. By this point, 4,400 had been built.

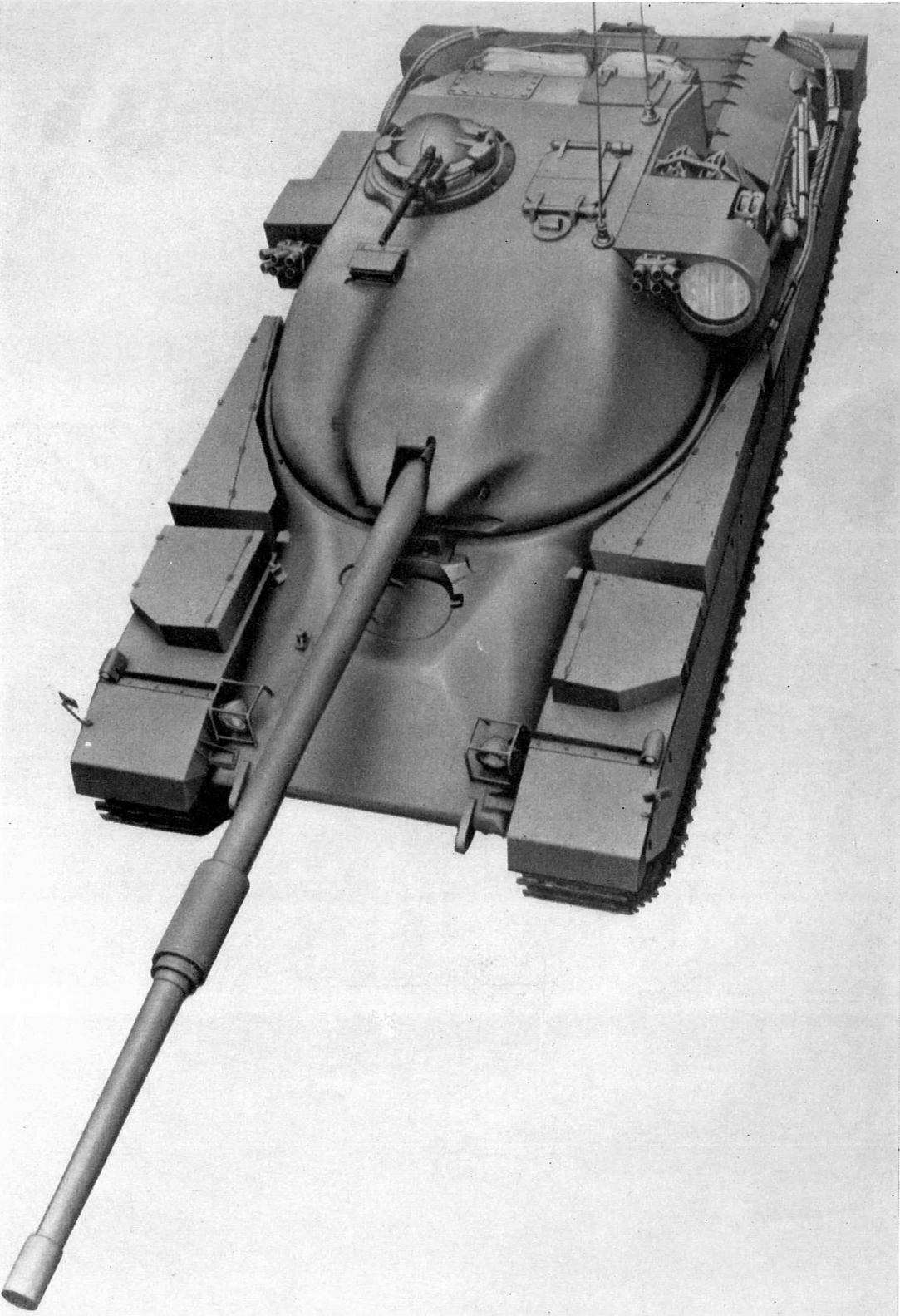

Chieftain

In 1951, the General Staff started work on what would come after Centurion and Conqueror, Medium Gun Tank No.2, more commonly known as Chieftain.

Two designs were evaluated as part of initial scoping studies, both based on a Centurion. The first was designed FV 4201 and used a US T-95 turret, and the second, designated FV4202, used a QF 20 Pounder armed turret.

As can be seen in the image above, this vehicle had a low profile, achieved by using a recumbent driving position, that would be adopted by the Chieftain designers.

In 1958, the General Staff Specification was issued, for what would be Chieftain, recycling the FV4201 and FV4202 designations.

Leyland produced the first mock-up of Chieftain in 1959.

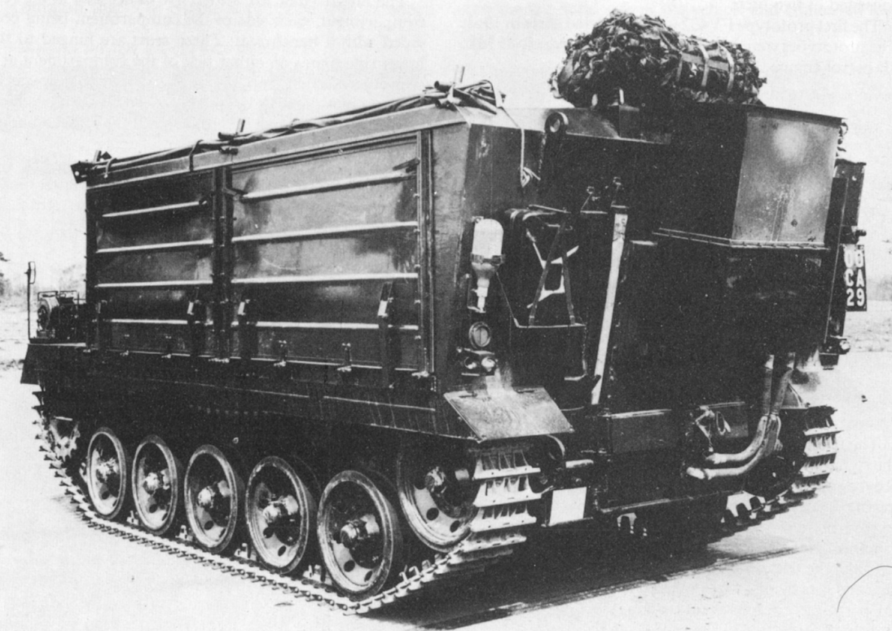

Tracked Carriers

The British Army made extensive use of US Half Track vehicles during WWII and continued to do so in the immediate years after.

A few Oxford Carriers were built, but these would be replaced. The first FV410 Cambridge Carrier prototype was built in 1950, also using the same Rolls-Royce B Series engine as many of the vehicles described above.

The direct forerunner of the FV432 is the FV420 series of vehicles, developed in the late fifties.

The FV420 vehicle family was to comprise; the FV421 Load Carrier, FV422 Armoured Personnel Carrier, FV423 Command Vehicle, FV424 Royal Engineers Section Vehicle, FV425 Royal Electrical and Mechanical Engineers Section Vehicle and the FV426 Orange William Anti-Tank Guided Weapon Vehicle, although only a small number were built.

Using experience from the FV420, the FV421 Load Carrier was the first of the family.

It had an armoured front section with the ability to carry a 3-tonne payload. FV421 was also amphibious and could be fitted with ammunition stowage racks, quite innovative for its day.

Artillery Vehicles

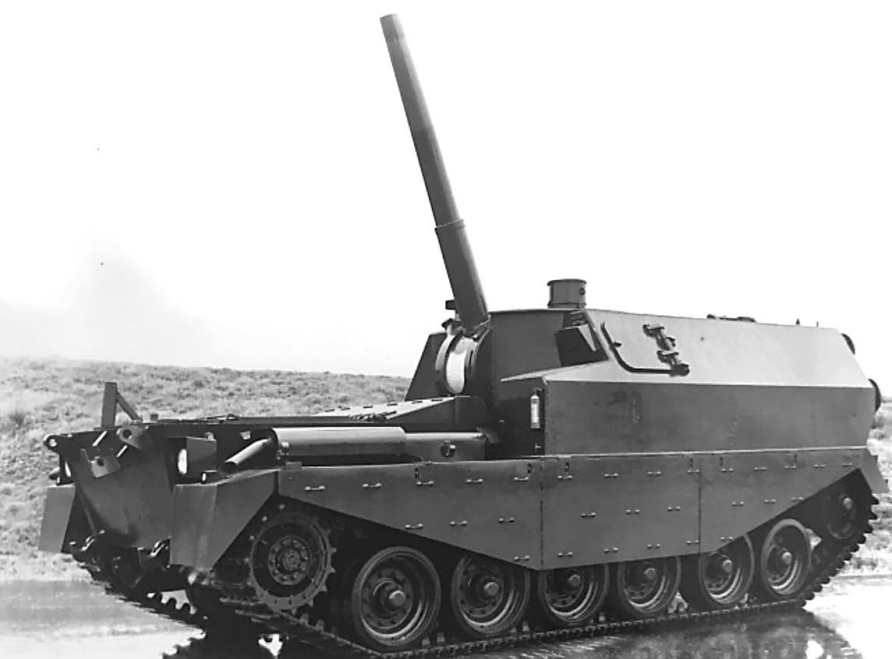

Although the post-war story of British Army vehicle recapitalisation is relatively positive, self-propelled artillery is less so.

The Royal Artillery would eventually receive approximately 50 M44 Self Propelled Howitzers in the mid-fifties to replace the WWII vintage Priests, but in the interim, the Centurion-based FV3800 series would provide valuable insight for future self-propelled artillery vehicles.

The basic requirement that underpinned the FV3800 was that it was mobile enough to keep up with armoured formations and protect the crew against enemy artillery.

- FV3801, Gun tractor

- FV3802, 25 pdr SP

- FV3803, Command Post Vehicle

- FV3S04, Section Ammunition Vehicle

- FV3S05, BL 5.5” SP

- FV3S06, BL 7.2” SP

- FV3807, 120-mm SP A/Tk

The image below shows an FV3805

With the widespread adoption of the US 105 mm artillery system, work on the FV3800 series ceased in 1957.

The Royal Artillery issued a requirement for a 105 mm self-propelled gun to meet close support requirements in 1958, eventually met by Abbot.

Summary

Suez, Korea, the Grant of Independence and withdrawal from Empire, and the 1957 Defence White paper, would all influence British Army thinking and its vehicles in the fifties, but it was WWII that set the foundations.

At the beginning of the decade (and slightly before), the British Army set out an ambitious programme of design, development, and manufacturing based on the principles of clear requirement setting and component standardisation.

These principles were not abstract, they were the product of the hard yards of 6 years of war.

For transport vehicles, the CT, and GS split was less successful, with only the Leyland Martian, Humber 1 Ton and Austin Champ entering service.

Much more successful were the AEC Militant, Land Rover and Bedford RL, all three being manufactured in large quantities, seeing many years of service, and massive exports.

Although ideal, and based on actual combat experience, creating military-specific vehicles (CT) for transportation was simply too expensive and ultimately, the idea was abandoned.

The standardisation approaches with more combat-oriented vehicles, such as Saladin, Saracen and Ferret, were a considerable success, vindicating the desire to learn from WWII.

For tracked vehicles, the Centurion was an undoubted success, and we must not forget the FV421 either!

By the end of the decade, all the lessons of WWII had been distilled into families of vehicles that were much easier to maintain, with high levels of standardisation.

- Lightweight armoured wheeled vehicle, the Ferret

- Medium-weight armoured wheeled vehicle, Saracen and Saladin

- Centurion tank

- Land Rover

- Bedford RL

- AEC Militant

- Humber 1 Ton

All were used operationally, all were exported.

The next decade would see more change, as Europe and the withdrawal from Empire would continue to pull the British Army in two directions.

To close, the 1953 Christmas Number 1

Begging bowl time!

I seem to recall there was a proposal to fit a 25pounder into the Saracen to provide a self-propelled

gun version but fell victim to cost restraints…With the purchase of Boxer we seem to be re-inventing the wheel!

When I joined a REME unit in 1990 before GW1 we still had Militants in the Stores Pl. ( Replaced just in time to deploy to the Gulf with Bedford 14t) and I have vague memories of a Bedford RL "mashie wagon" in one of the REME sections…. Moreover there were definitely Ferret scout cars deployed to GW 1 So the legacy endured way beyond the 1970s….

Cheers TD. Another excellent read

Interesting that you mention thread commonality as being a big motivator in vehicle and engine design post WW2

The Ferret has a B60 engine with large letters UNF stamped on the Rocker cover. Nothing else, no manufacturers name etc.

I have always wondered why the thread type had so much prominence. Now I know

Fantastic article TD

It does make you wonder, as the mk1 pig looks remarkably similar to foxhound, the 6wheelers similar to some of the French vehicles and obviously Israel took the Churchill, ran with it and ended up with the excellent Merkava/namer (bargain at £6m).

What is also quite startling is how industry and MOD seemed to work together..

Given our current capabilities within aerospace, space and car manufacturing, it’s pretty astonishing we are not world leaders in UAVs and military vehicles..

If Sweden can produce Gripen (lots of Uk content) and France their wonderful range of vfm wheeled vehicles, why can’t we.

The MOD could do worse than read this article, take stock, perhaps look at Chris’ AEC article as well and start the process of really getting the land show back on the road.

Surely we can use the JCB supply chains to start with

If standardisation is king then it’s boxer wheels and tracks all round, with SEP wheels and tracks providing a smaller version of similar capability for the majority of the armoured combat fleet (accepting Ajax as an outlier).

We are probably looking at 50-60k vehicles for the whole MOD of which c. 20k will be armoured combat for the army. So this is 750 armoured vehicles per year and 1500 other types (Inc. 10k LR replacements, 10k white vans, 10k HX3’s, 10k other types).

So we do have the scale to setup an industrial capability in the UK, do we have the political willpower.

For once, let’s be more French…

The Conqueror was still running in the early ‘60s. We had them in Hohne. Beautiful beast.

TD, excellent article and well researched as always. As BP pointed out the Ferret was still in-service when I had one in the 80's. A quick Wiki search showed "Production finished in 71" and they were withdrawn from UK service in 91. A typo rather than an error, so still worth me buying you a coffee !

The reality is this is not hard.

We already have the base unit for wheeled vehicles. What we need is to develop the modules to go on the base Boxer chassis. This should not be hard, we have over 200 40mm turrets and guns laying useless after the elimination of the Warrior upgrade. You give Ampthill 6mths and 5 Boxer modules (Bought from overseas) to get that turret on the vehicle. You then spend the next 10yrs buying 100 Boxers a year. That should within 3yrs give you a wheeled Brigade supported by towed 105 or 155mm artillery using upgraded Mastiffs to do the pulling. (I have been very surprised by the effectiveness of towed artillery in Ukraine)

At the same time we have the Jackal which needs to have a Cab placed on it to provide some form of protection from small arms and shell splinters plus from the weather for the recon role.

These already exist and in some cases we have already bought the equipment. Just get on with it, its neither costly or impossible. There will be people who go "Ampthill lost its developers" well either they get their act together or someone else does it. Its about time we had a can do attitude instead of a lets make it last 20yrs development to wring as much money out of UK PLC as possible. And if private industry can't do it, re-establish the Royal Armaments Factories System. I am sure some managers from JCB or a number of other UK manufacturers could get it up and running in months.

The threat of war is constant. We require a constant solution or by another name infinite game..

https://www.youtube.com/watch?v=0bFs6ZiynSU

So this constant situation where by: oh now we have to think about building something because its failing, ie being Reactive rather than proactive. you know like germany or the USA's procurement schedule/ accessment time table.

I equally find it annoying that we have one of the most expensive militaries yet middling quality and/or little to no exports. We seem to fail at economy of scale. the USA, china and russia all excel at it. through population willing to buy the products (ammunition) or scale of factories. Or the german model of leasing assets and fractional purchasing. where you get a base vehicle and module up, so this year you get a tank. next decade you get better armour, or optics, or electronics.

Our army changes priorities on a whim in government as well. you dont need a gun for national aid during covid, or lorry driver shortages.

Its a mess of half measures and double problems.

I tried to get into the army in mid 1966 at the careers office,was told they had no room for mechanics so I joined up in 14 sept 1966.Did my basic training at Royal Electrical & Mechanical Engineers – REME

Depot Poperinghe Barracks.doing my traning one day I was told to go to the main offices,I was asked did I want to be a driver said NO it was the only way I could joint,RIGHT go to the back room & we'll give you a test.I passed it,you are now going on a course to be a mechanic after your taining.It would cost me £20.00 now to buy myself out of the forces,you are doing 6yrs in the army & 6 reserves.I passed out starting my training at S.E.M.E Bordon,Hants,I enjoyed it for that year started with my driving test at end of 2 wks I was put forward for my test in a Bedford RL driving around Southhampton and passed first time,I was on my course for 1year to become a mechanic came second in the test I got so I had second choice of a posting I could choose what I wanted,Decided to go to West Germany.I got posted to many places and excercises in the far east,west Germany 3 times UK 2 times Gibraltar 1 time for 2yrs,N Ireland 4mths then short stints.Been to Batus training area in Canada,I became a full corporal then went on my first class training course to become a mechanic,I did not want to be any other rank higher because of the mess fees.I became an inspector at 12 armoured workshops.Left the forces doing 18+ yrs and enjoyed it once I had finished the basic training which was to get you woken up and speed uniform changes then locker checks,bed blocks,running everywhere around camp,Very,very short hair cuts(I never used my combe hair was so short.I met many men in the forces of the infrantry & other trades.